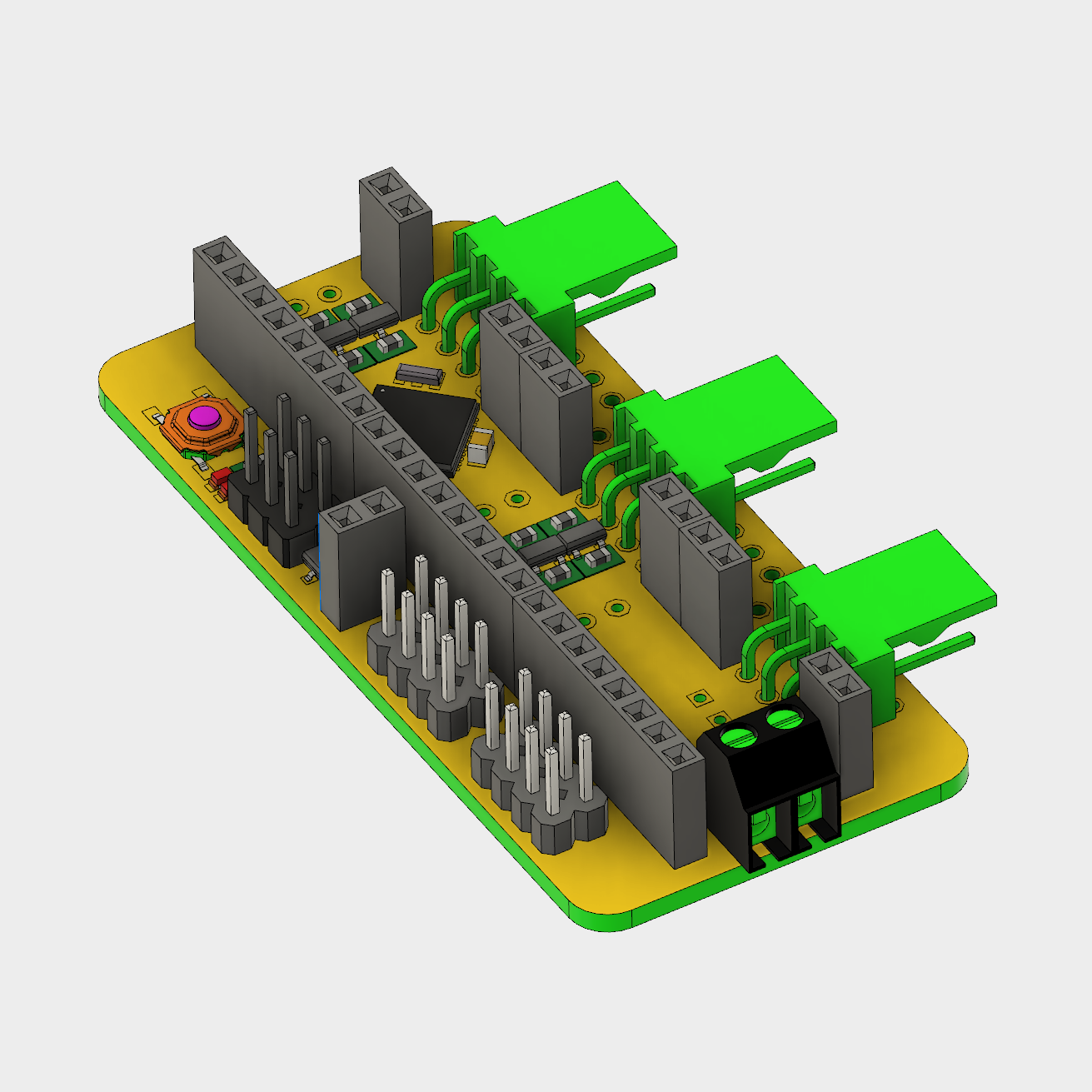

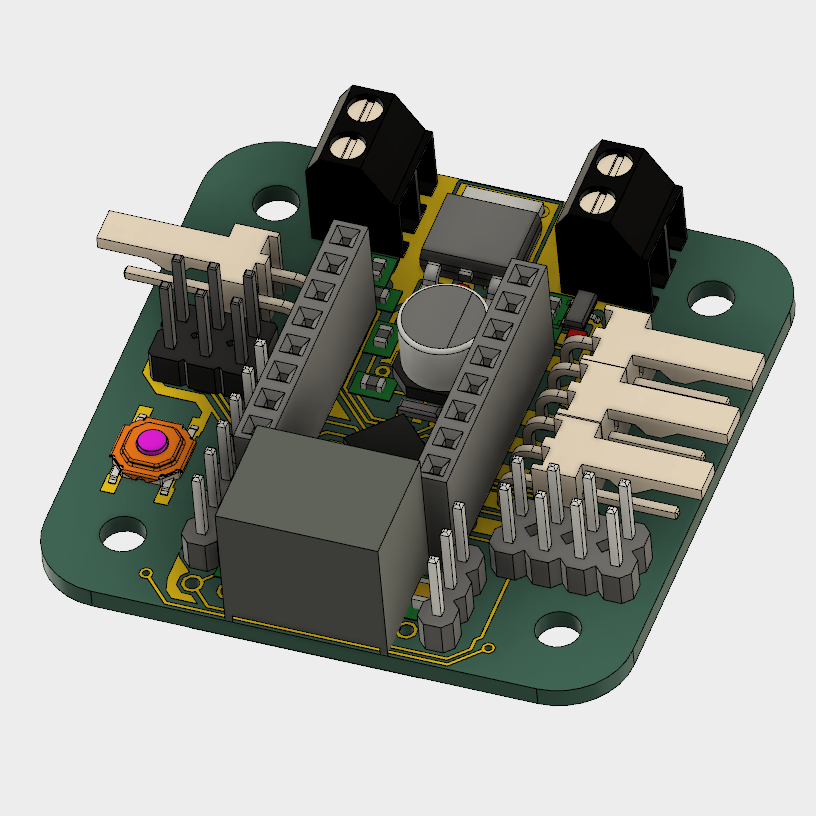

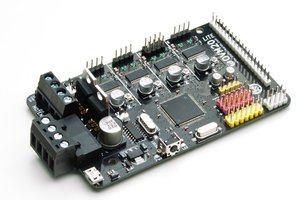

Features (stepZeroR1)

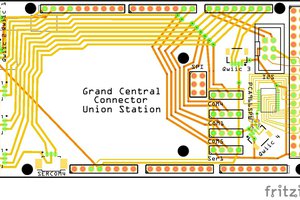

- ATmega1284p Sanguino (Arduino compatible) core running at 20MHz

- Switching regulator DC-DC converter to power the RPi (1.5A OKI-78SR)

- Communicates to RPi via UART to upload firmware and connect to OctoPrint

- Headers for three StepStick stepper drivers (micro step adjusted via solder jumbers)

- Connectors for three end stop limit switches

- Four expansion ports (I2C based) for driving extruders, heated bed, spindle, etc

Mo Badr

Mo Badr

derethor

derethor

Uriel Katz

Uriel Katz

bobgreenwade

bobgreenwade

Alastair Young

Alastair Young

You should check out https://github.com/KevinOConnor/klipper for software juiciness.