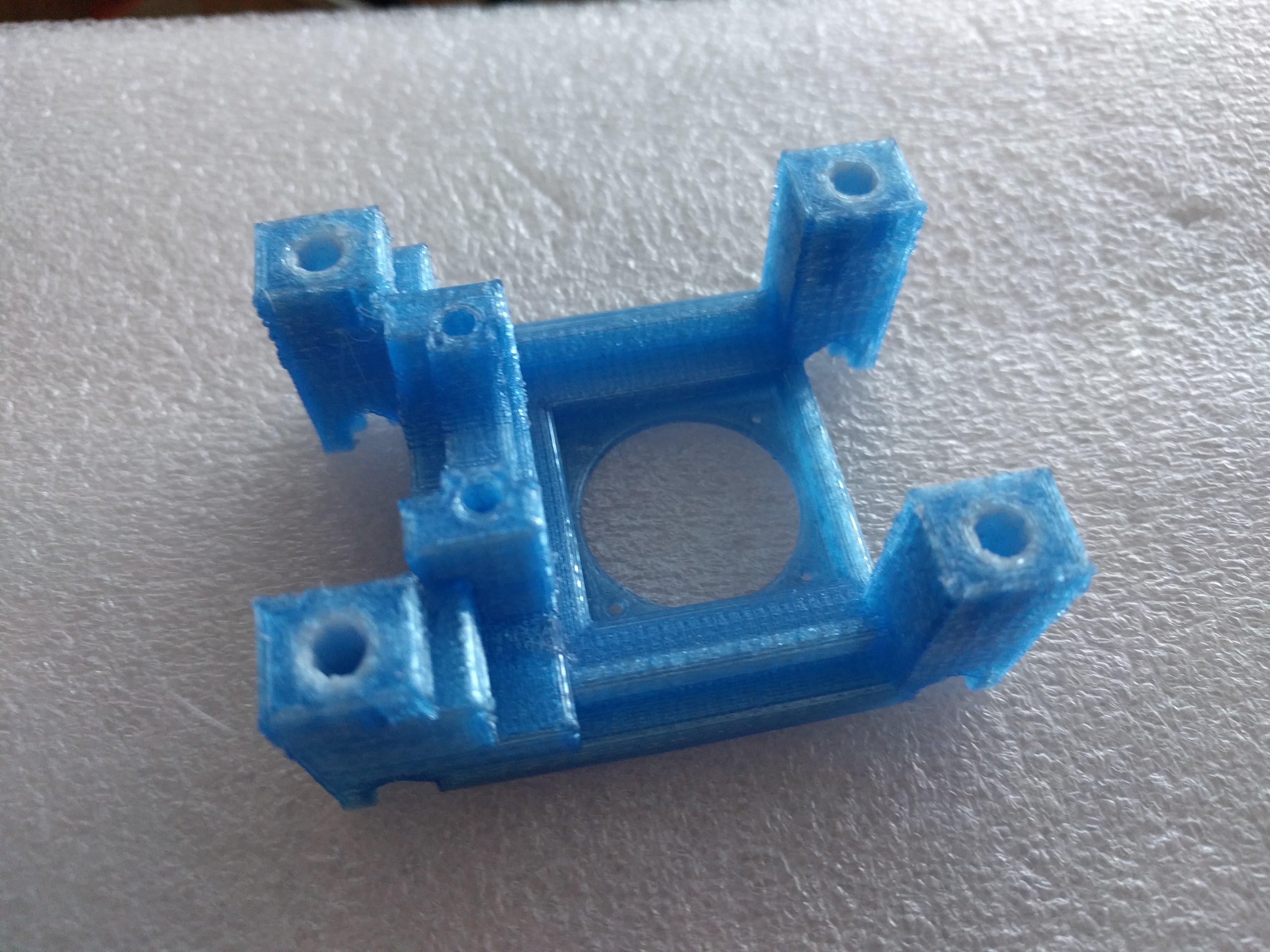

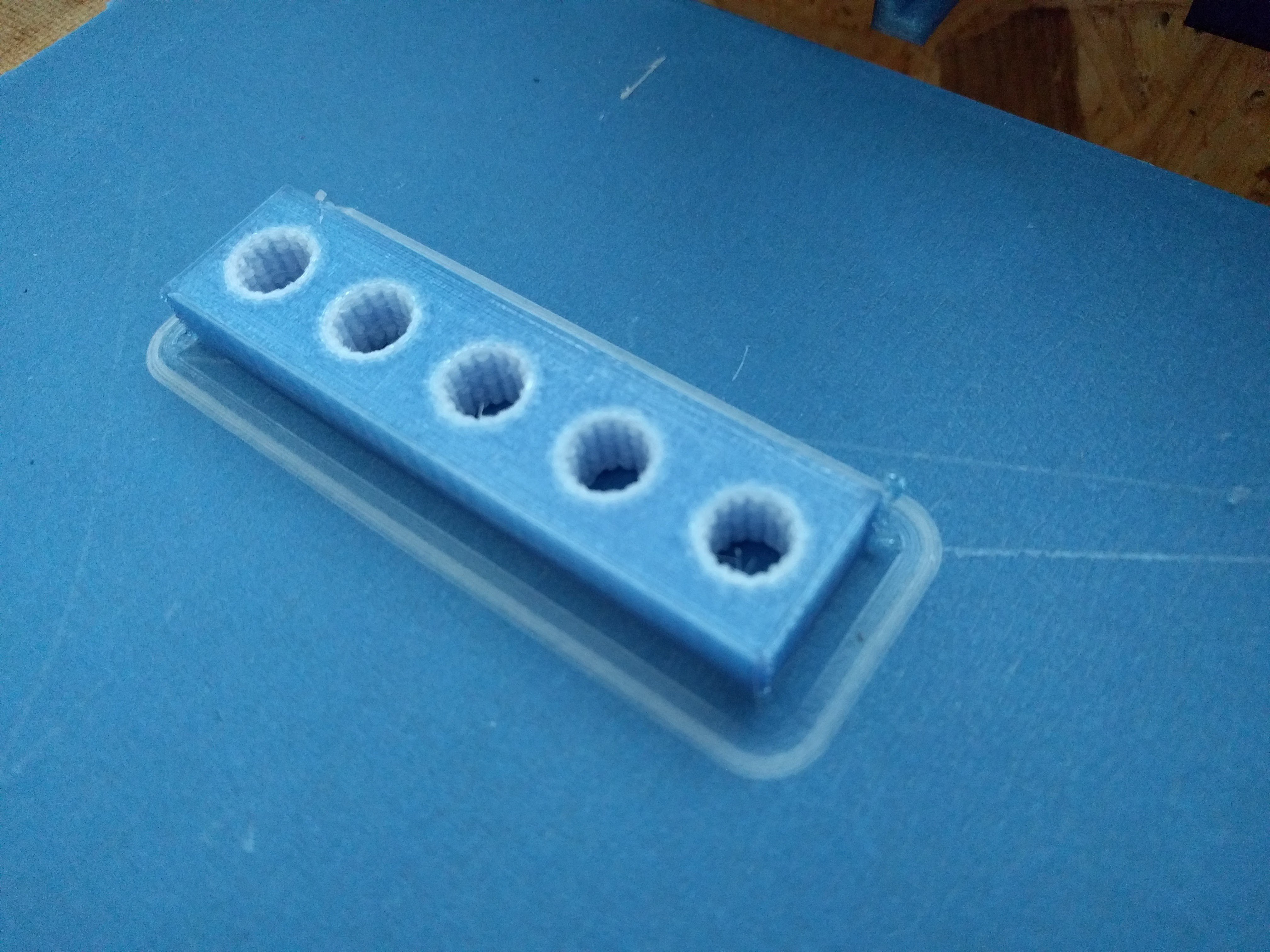

The project entered a new stage, the prototype is good enough to bootstrap itself to print better parts. Below is an image of the hotend fixture that is printed in PET-G (light blue) and POM (white, low friction wear resistant) to replace the previously used brass bushings.

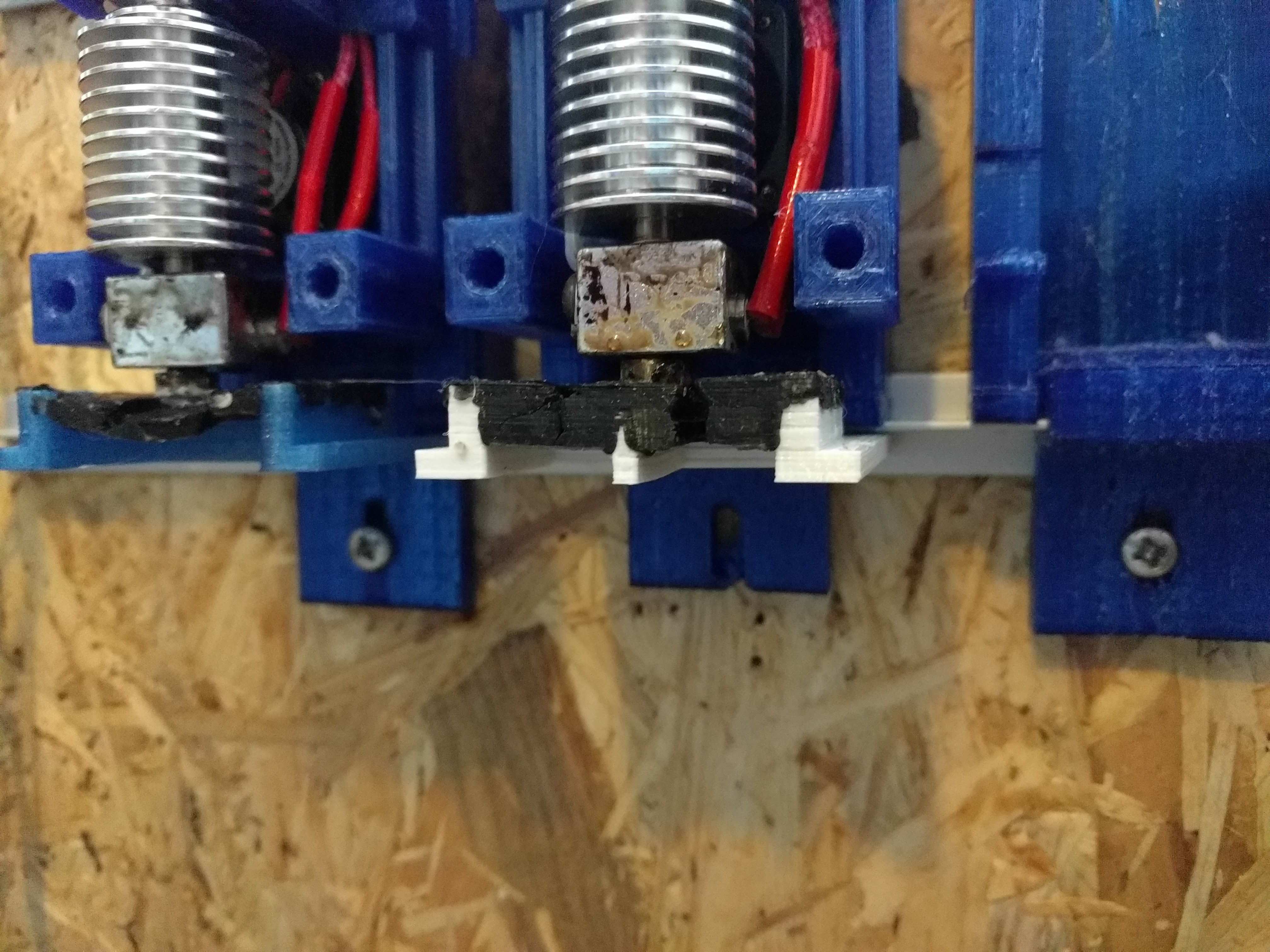

The joint between the carriage and the hotend is now made out of four printed 4mm bushings (instead of two brass) and four 4mm shafts. Loading and unloading is now faster and smoother. The overall design is very compact and forms an air duct to guide cooling air down to the printed part.

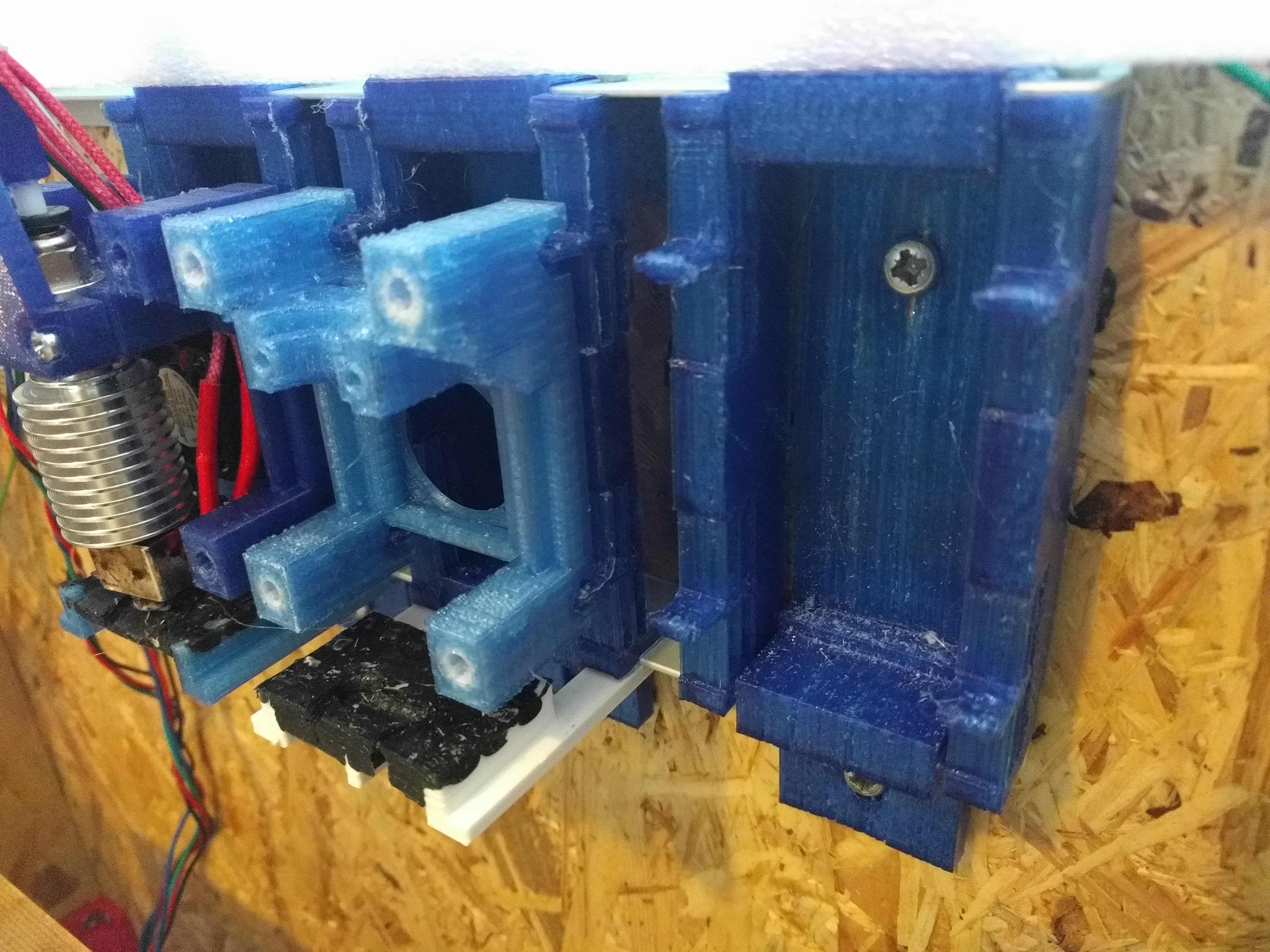

carriage without hotend

carriage without hotend

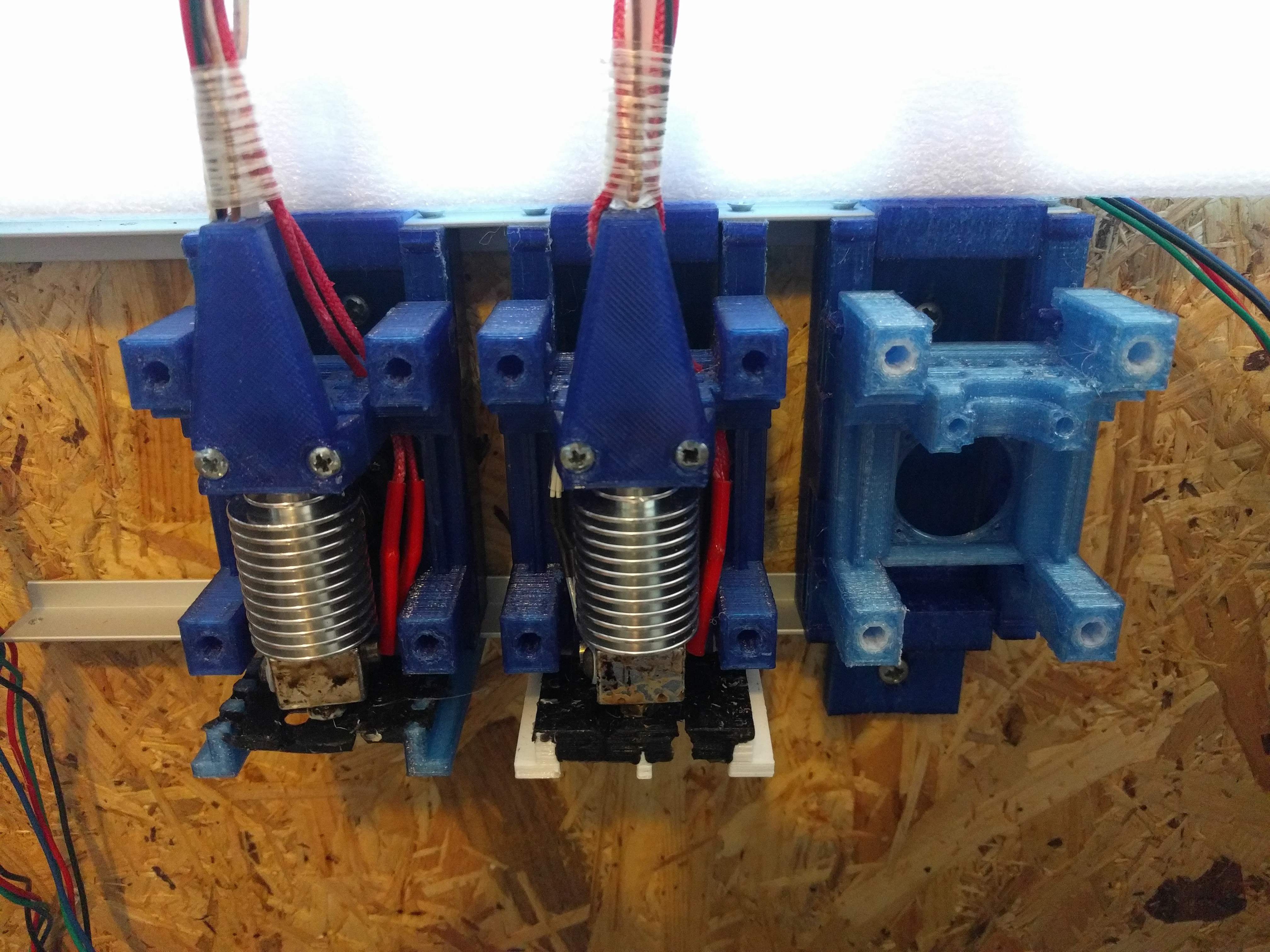

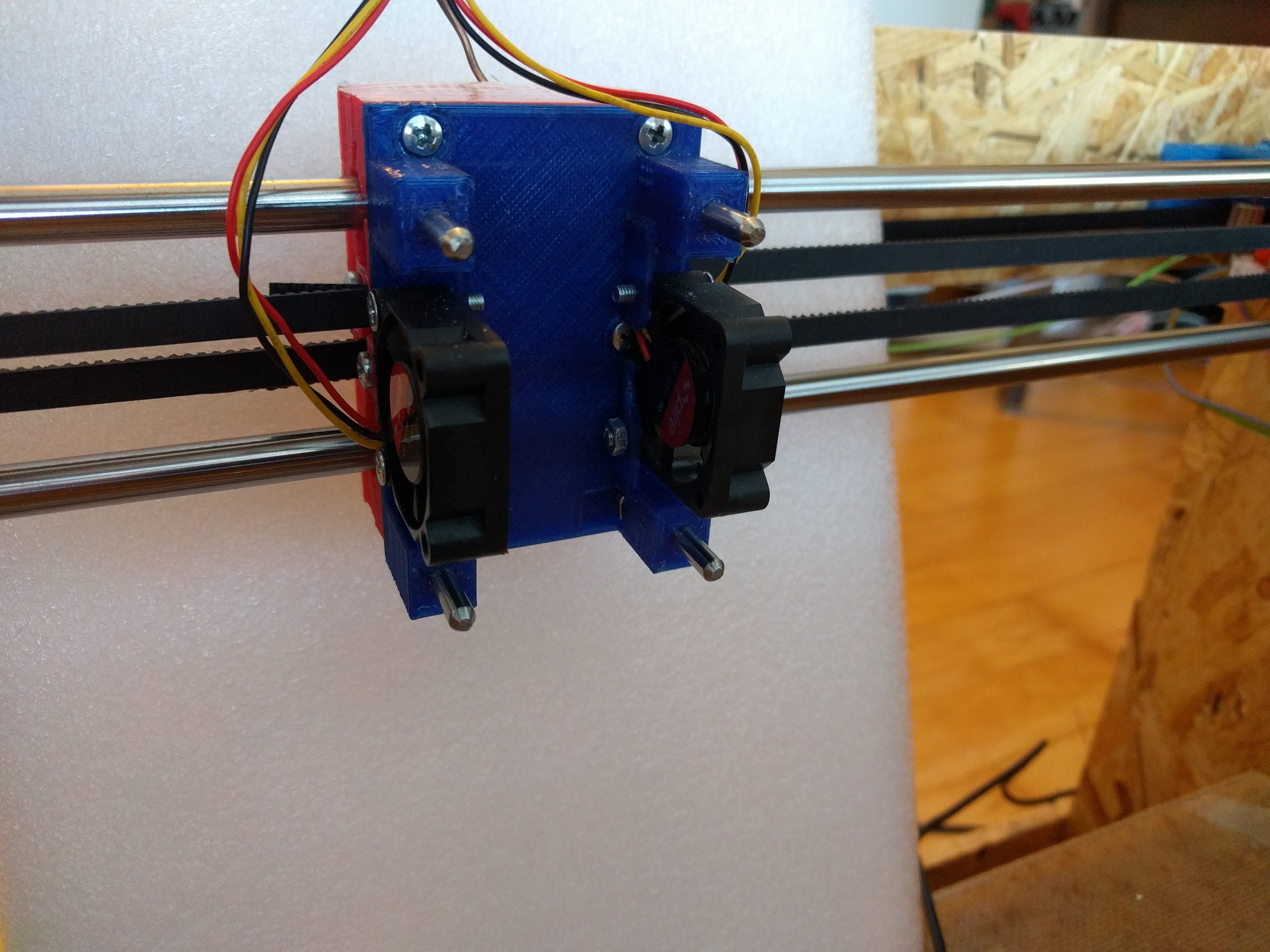

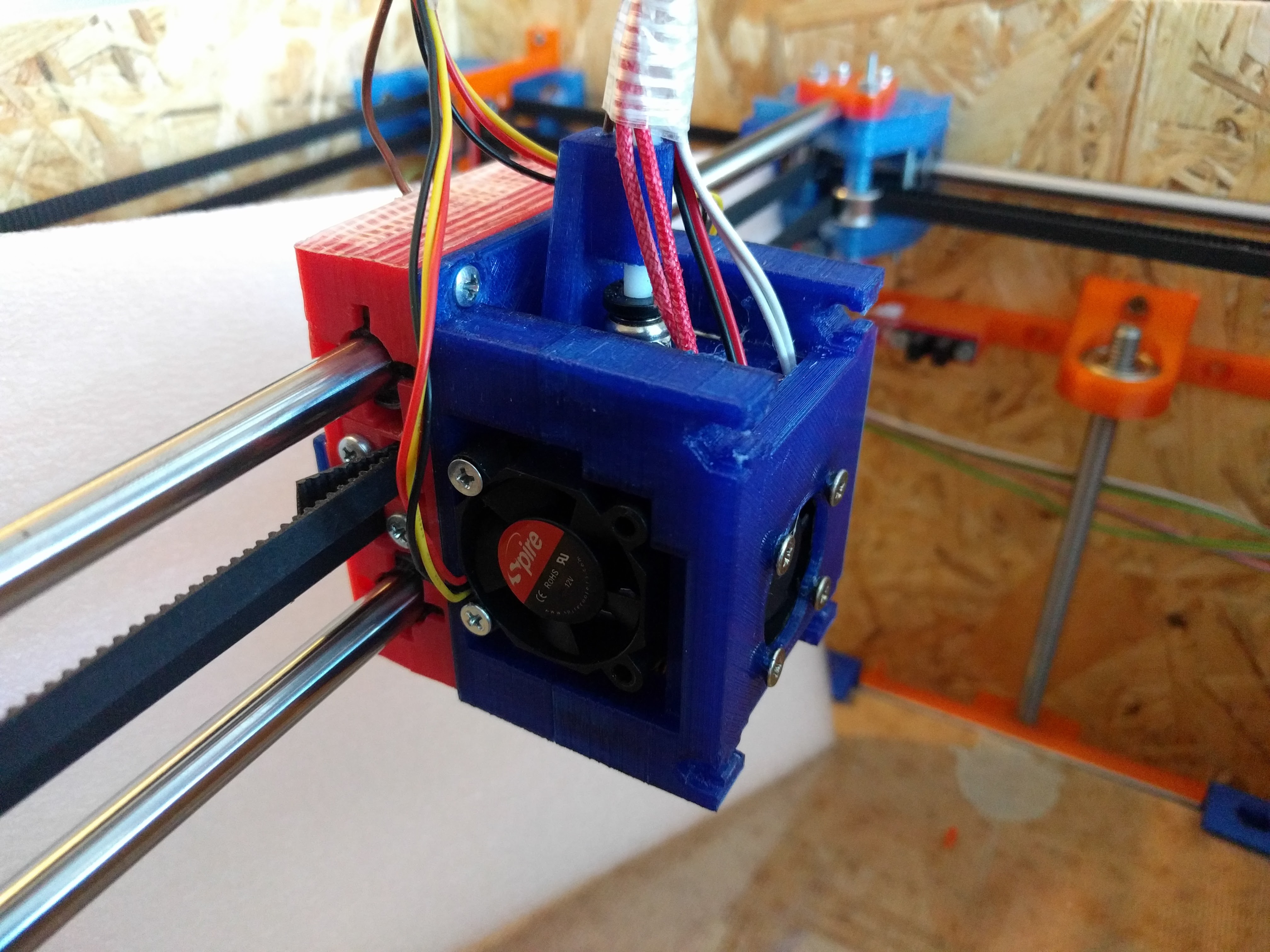

carriage with hotend

carriage with hotend

Four pins and holes are now used to provide a enough support for unused hotends sitting in the rest. It is possible now to block the nozzles with a silicone wiper and prevent oozing. Additionally, the hotend is now moving in only one direction over the wiper, which reduces the chance of picking up previously removed filament.

This is how printing looks like now. The short stops after loading are because Cura reduces the hotend temperature (15°C) while it is unused and then needs to wait for the hotend to heat up again. In between the code has been fixed and the pause happens while the nozzle is blocked.

This is the finished part. No prime tower and cleaning. I'm very pleased with the result.

rolmie

rolmie

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.