UPDATE: V3 includes an on/off switch!

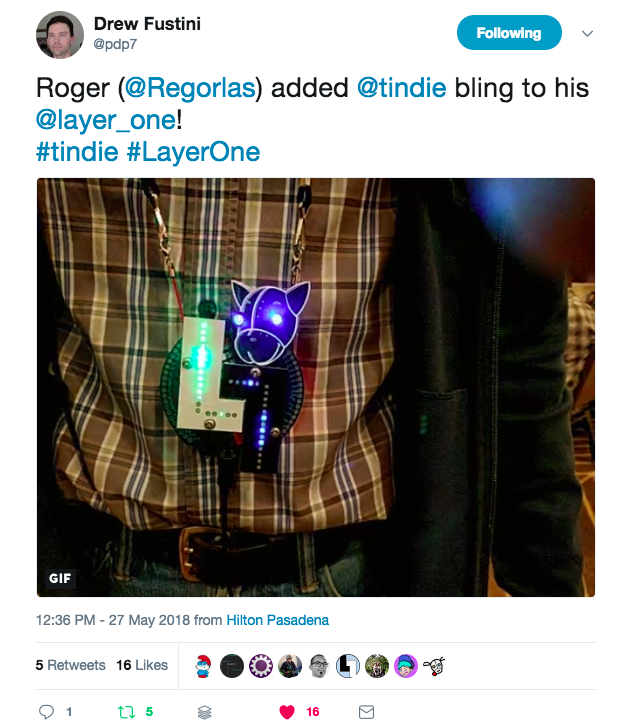

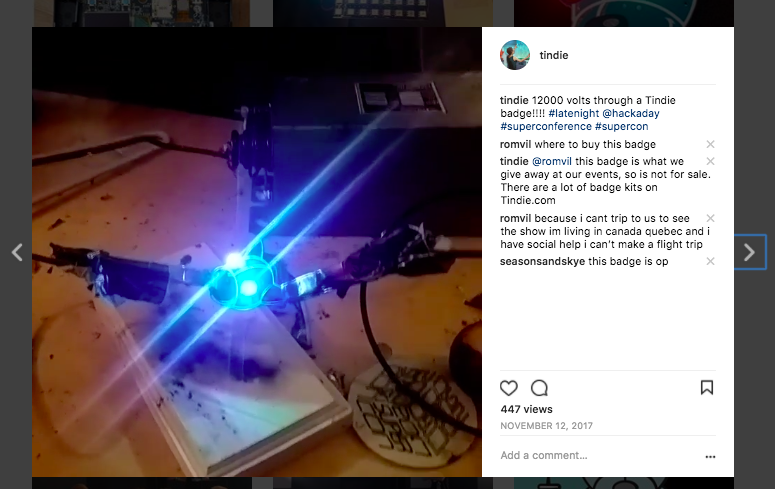

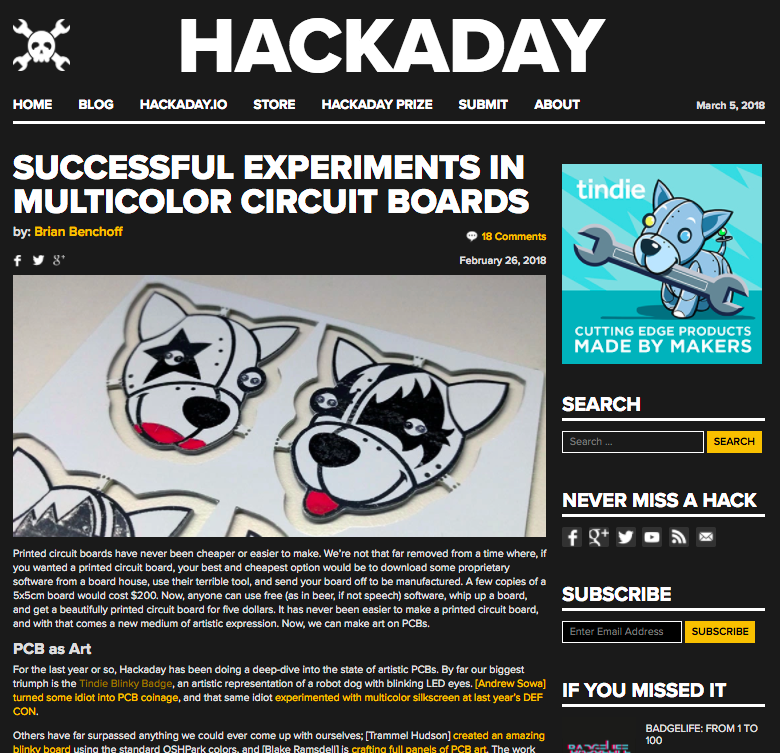

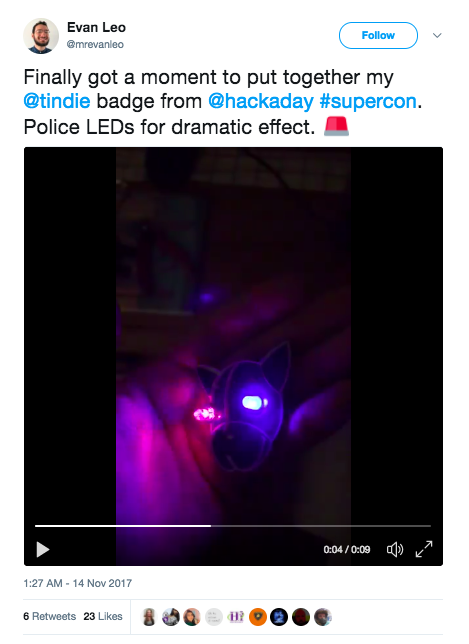

Read Brian Benchoff's post on Hackaday about how this all started when we wanted a badge for DEFCON 25 in under two weeks. Once we got back we realized that it could be made better with a switch and cheaper with BOM cost optimization and the badge iterations.

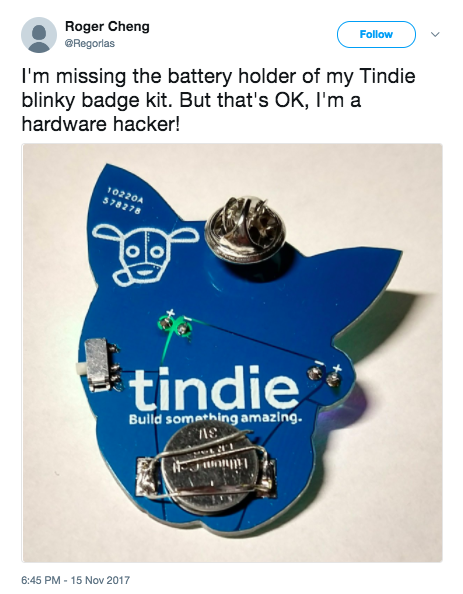

Tindie

Tindie

Follow

Follow

awkward intelligence

awkward intelligence

Benchoff

Benchoff

Mike Szczys

Mike Szczys

Can you post the gerbers for just one badge and not the panel?