The first concept of the Adaptive Guitar was actually a lot different from it's current form. The original idea was to rotate a (custom) "pick" ( made of a flexible piece of plastic on an axle ) over the string to make it sound. While I considered using hobby servos, they were way too slow and noisy, so I figured I'd go straight to a more tailored approach.

Each string got it's own pick, and the picks are held in place by what I call the Pick Bridge (since it bridges the sound hole). Each pick was to be driven by a small rotary motor, connected to the pick by flexible drive shafts and custom couplers. Power and control was external...we'll talk about that later.

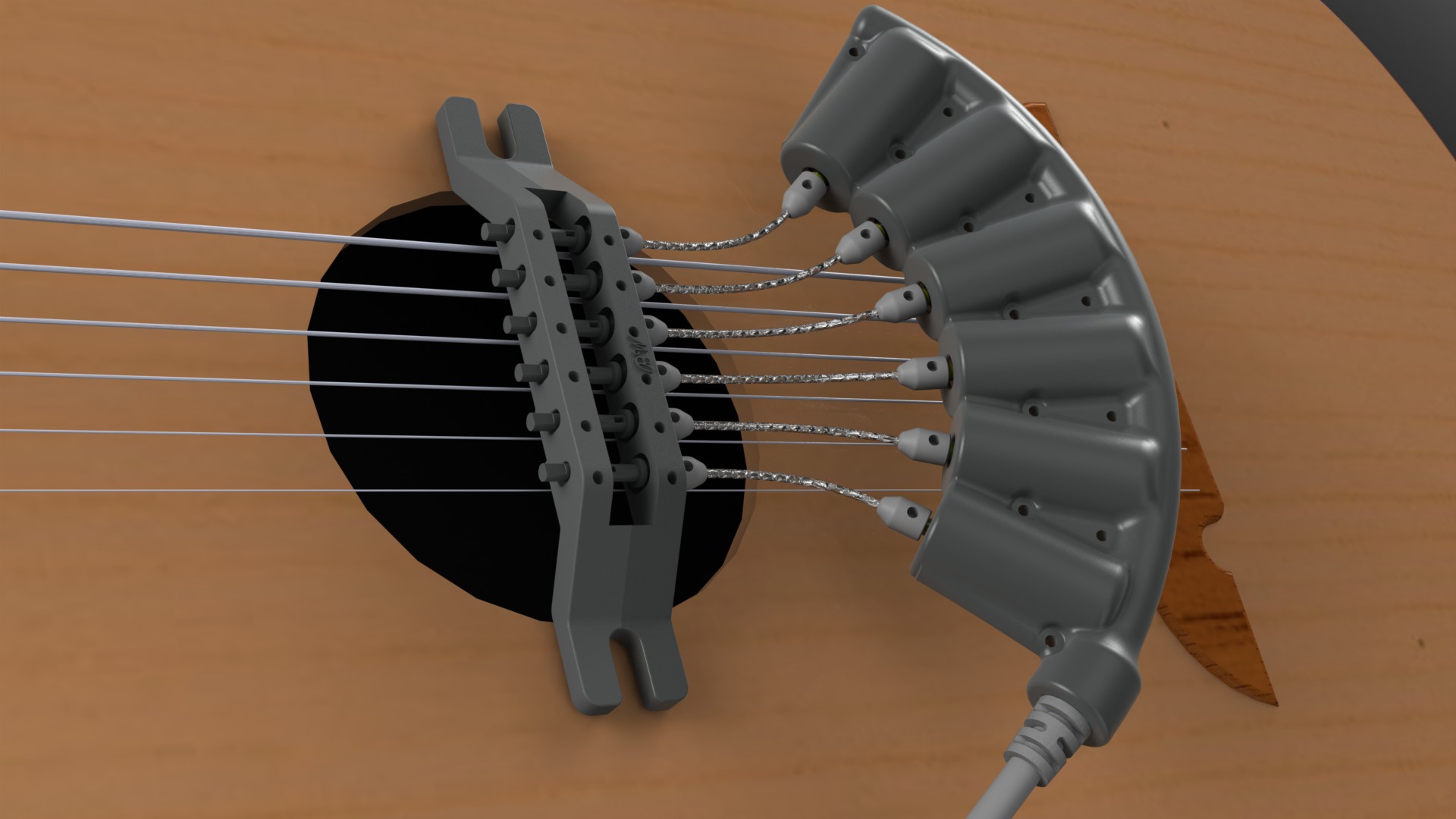

Here's an early render. There are certain elements missing, but you get the picture: A motor turns, which rotates the corresponding pick, which strums the string. Each strum is one revolution of the motor. The shafts are braided steel cables, similar to bike brake cables, but lighter gauge. I couldn't use rigid shafts because the motors were wider than the string spacing and couldn't be perfectly aligned. I thought of U-joints, but didn't know where to find any that size at the time. Note I didn't have the supporting features designed yet - I was just trying to get the main parts of the concept laid out, so stuff is floating...

The concept seemed solid enough, so I set off building my first iteration of the pick bridge assembly. Here's a picture showing the first Pick Bridge (aluminum at the time) and the original pick prototypes. The first prototype picks were made of a split pin with a piece of milk jug plastic pinched into place. Later, tried having them 3D printed (shown in orange, in position in the Pick Bridge).

Here's the Pick Bridge, mid-fab, showing my first mount concept, which required holes drilled in the guitar to mount PEM-type bolts. Thumb nuts held the bridge in place, and the slots on the bridge ends allowed horizontal alignment of the whole thing over the strings. I did all of the machining myself.

Here's the Pick Bridge, mid-fab, showing my first mount concept, which required holes drilled in the guitar to mount PEM-type bolts. Thumb nuts held the bridge in place, and the slots on the bridge ends allowed horizontal alignment of the whole thing over the strings. I did all of the machining myself.

Here's a test video. I'm not going to talk about the control box yet, so bare with me.

Two primary issues plagued this version; Most notably, the plastic parts of the picks quickly broke due to repeated bending after only short periods of use, and the sound was inconsistent and not very loud. The pick axles were a relatively loose fit in their holes on the Pick Bridge, so they made a lot of racket when they were turned or moved. Time to try something new!

Joe

Joe

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.