After landing on a successful iteration of the Picks and Pick Bridge assembly, it was time to construct the rest of the system; specifically, the part of the system I call the Motor Module.

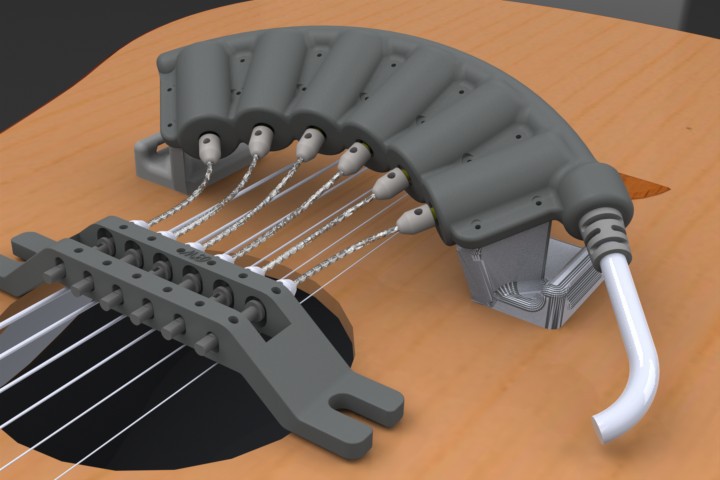

In case you didn't see my first log entry, the concept for Gen1 was to use motors to rotate picks that are held in place over the strings at the sound hole. Here's an early render (which you may have already seen):

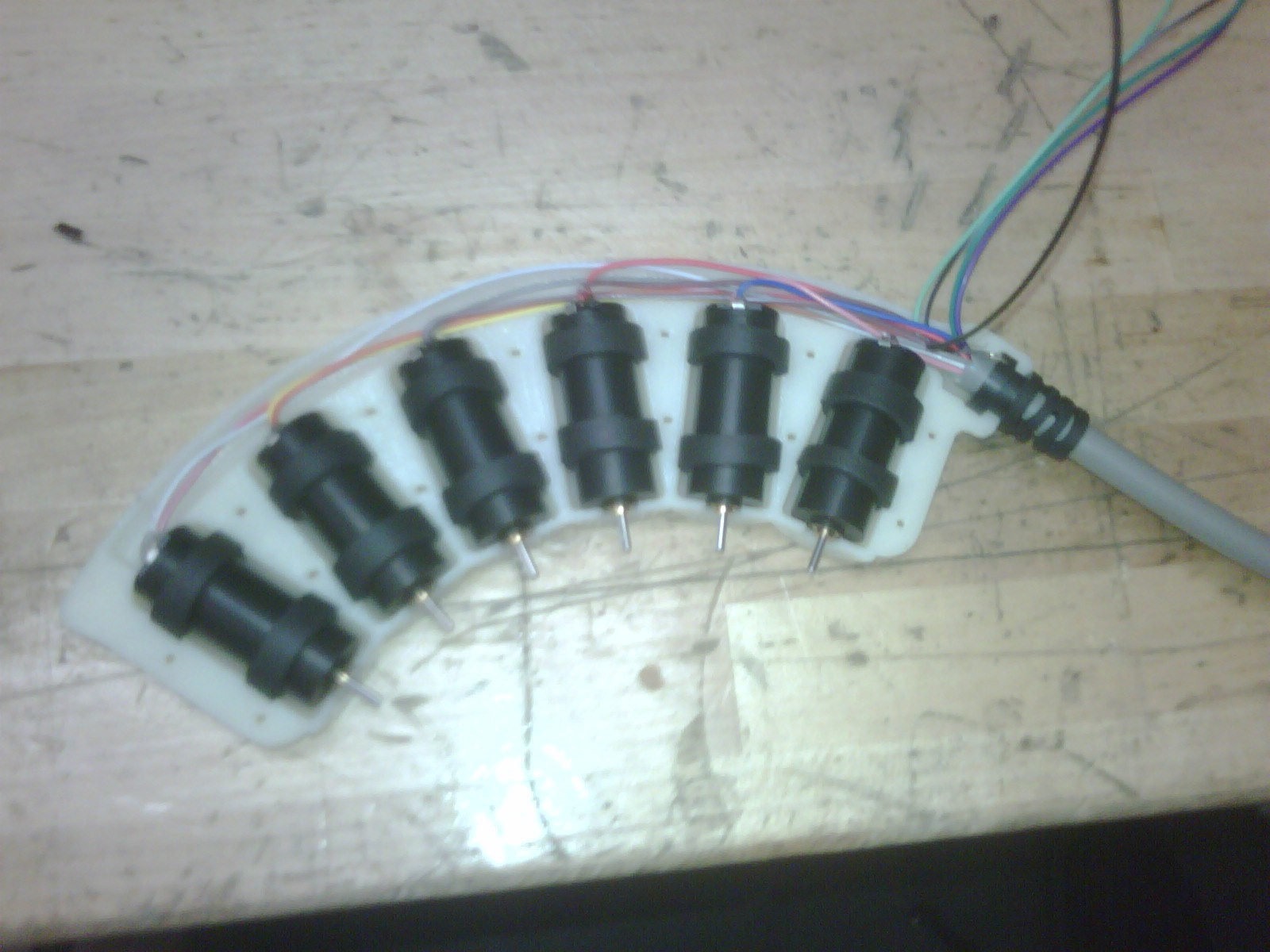

So now, I'll show you the innards of the Motor Module. The construction is pretty simple: A two-part housing, containing six brushed DC motors. Here's the Motor Module with the top half of the housing removed). The DC motors are from MicroMo, which were just set in place with some rubber isolation rings. The channel along the top was where I routed the motor power wires, which exited on the right side through a strain relief. As you can see, It's actually pretty small. The arc was diligently engineered so that the flexible shafts I used to drive the picks would fall into a natural bend.

.....AAAAAND.....here's the Gen1 system all together!

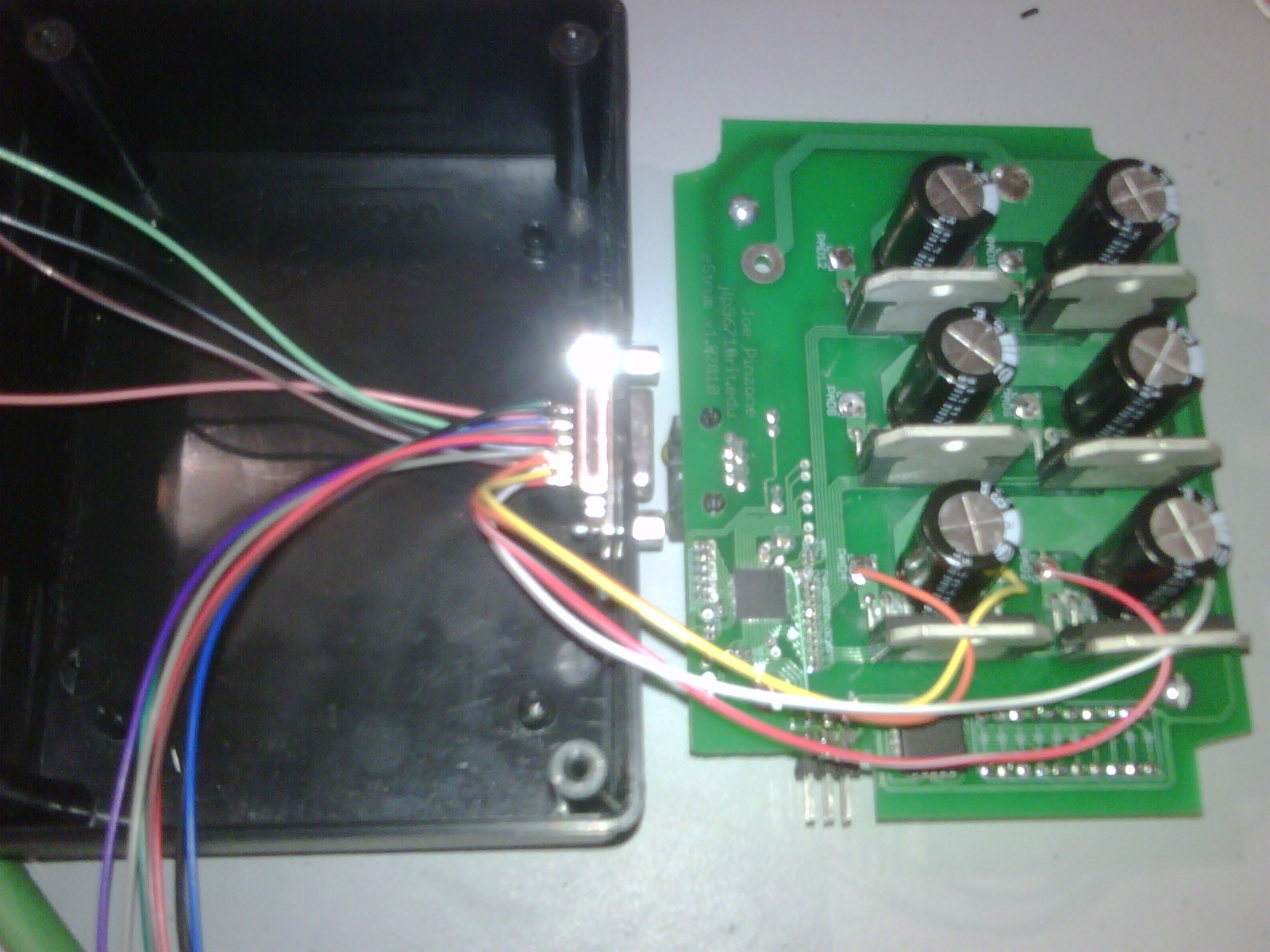

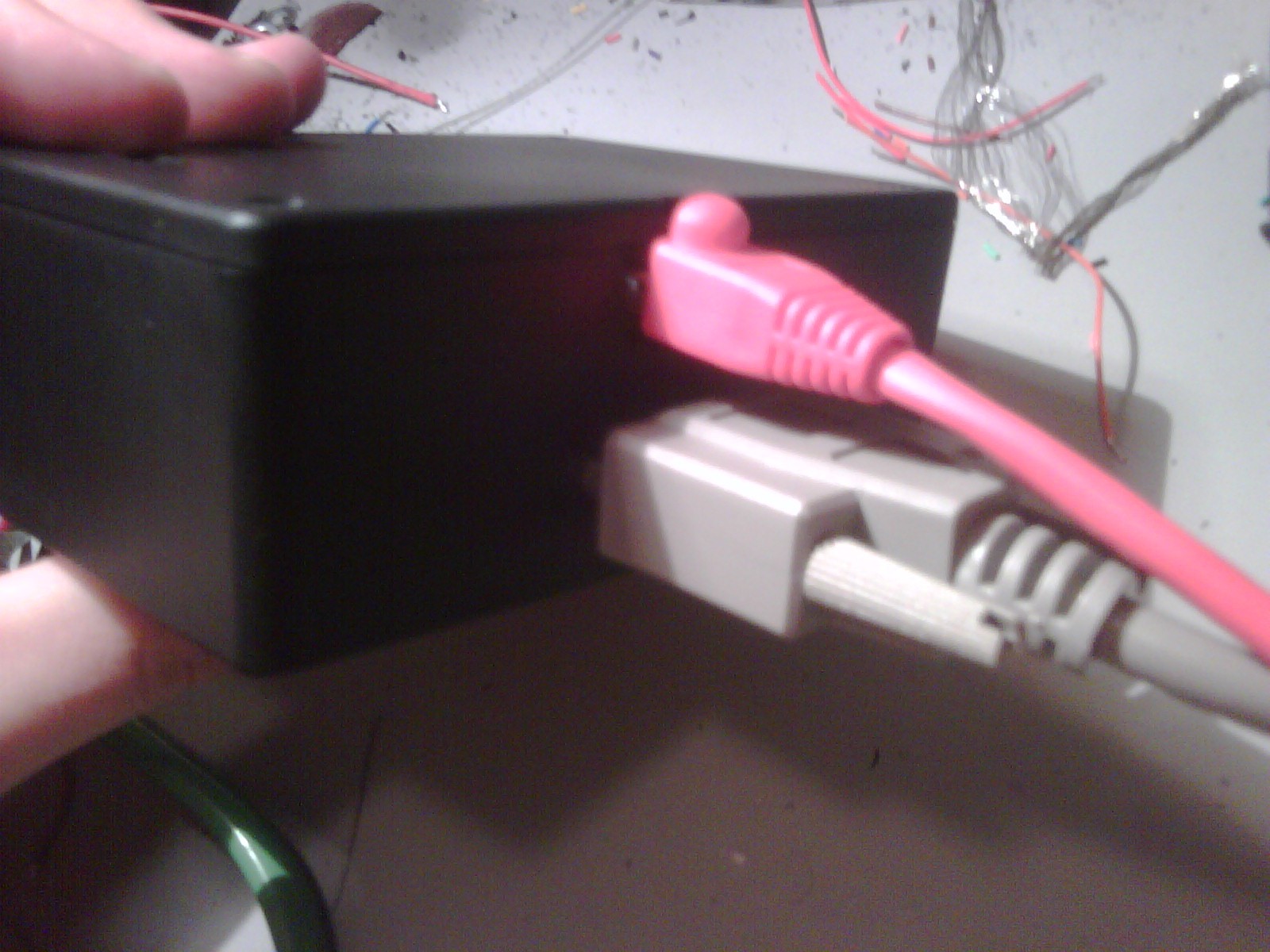

Now, what you haven't seen so far is the motor control box. The control box housed a custom PCB with an AVR MCU and six half-bridge motor drivers. The MCU took the analog inputs from the foot controller FSRs, and would control the half-bridges to rotate the motors/picks. This version used 12VDC power from a wall wart. A repurposed VGA connector was used to connect to the Motor Module, and an RJ45 connector (with blinky lights) was used to connect the foot pad.

A belt clip on the control box mounted nicely to the guitar strap while in use.

Here's a quick video demo of the first tests of the foot pad + controller box:

Here's a quick video demo of the first tests of the foot pad + controller box:

Unfortunately, I don't have video of this version of the system running, but it worked GREAT! It it had issues that eventually caused my friend to abandon it, though. The key issues were:

1) No encoders on the motors, so I was using time-based actuation (bad choice in retrospect). The picks naturally ended up wanting to stop touching the strings after their initial rotation, which caused an undesirable buzzing noise. Unintentional double-strumming was also an issue.

2) The flex shafts were too stiff and not balanced. the whole thing wanted to shake every time a motor spun as a result. Friction comes in many forms.

3) The picks were difficult to adjust to get the sound to be consistent. That's because as you fret a string, it gets pressed down and moves away from the pick bridge. This causes decreased strum intensity for strings that are fretted further down the fret board, and is really detrimental to making good music. After about 5-6 frets, the picks can't even contact the string.

4) She couldn't adjust or replace the pics herself without a lot of hassle, and this project was supposed to be liberating, not add more dependency on others.

Of course, I can't just abandon the project. On to Gen 2!

Joe

Joe

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.