Components:

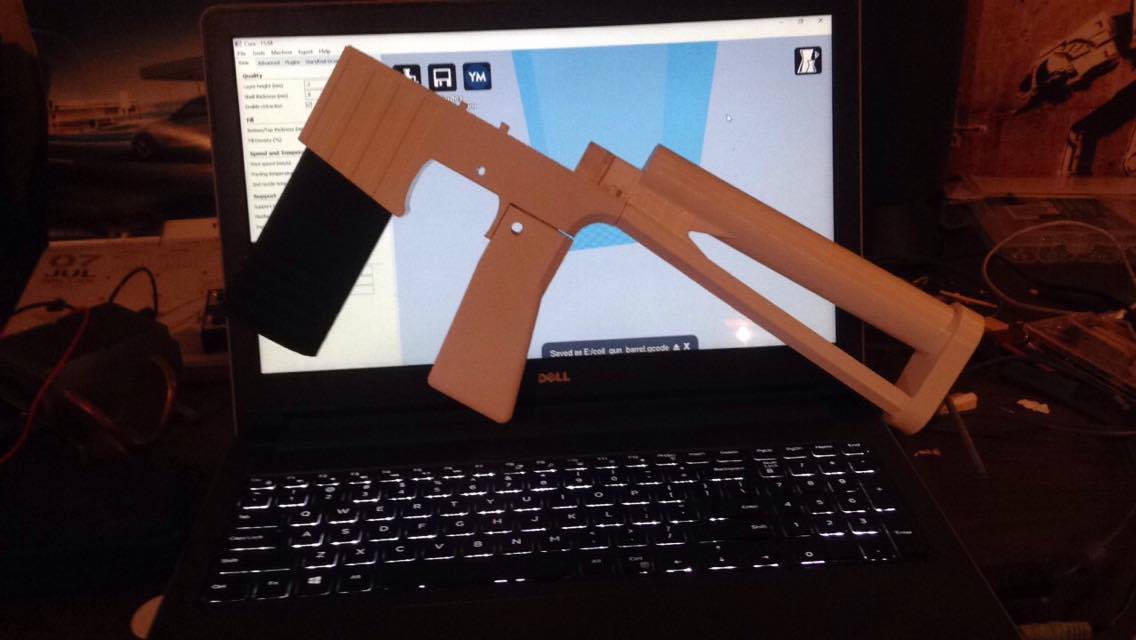

AR-15 lower receiver

short mag

butt stock

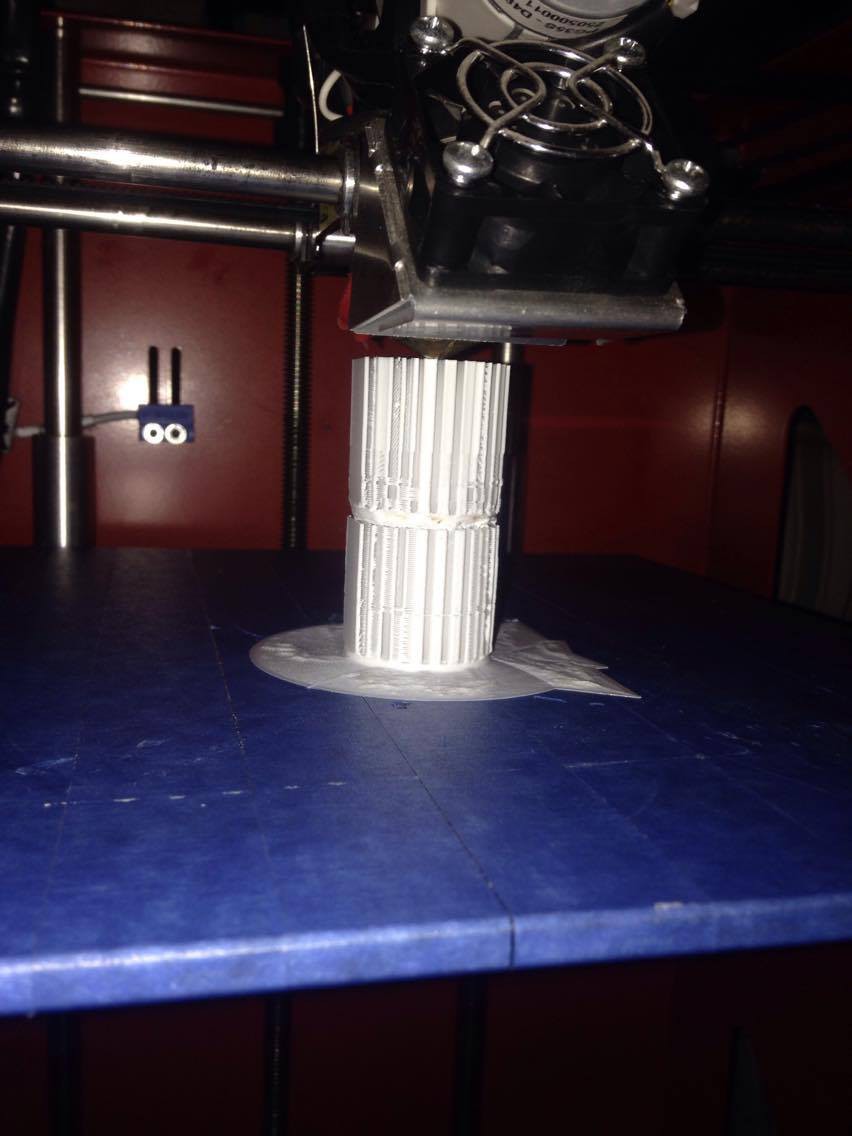

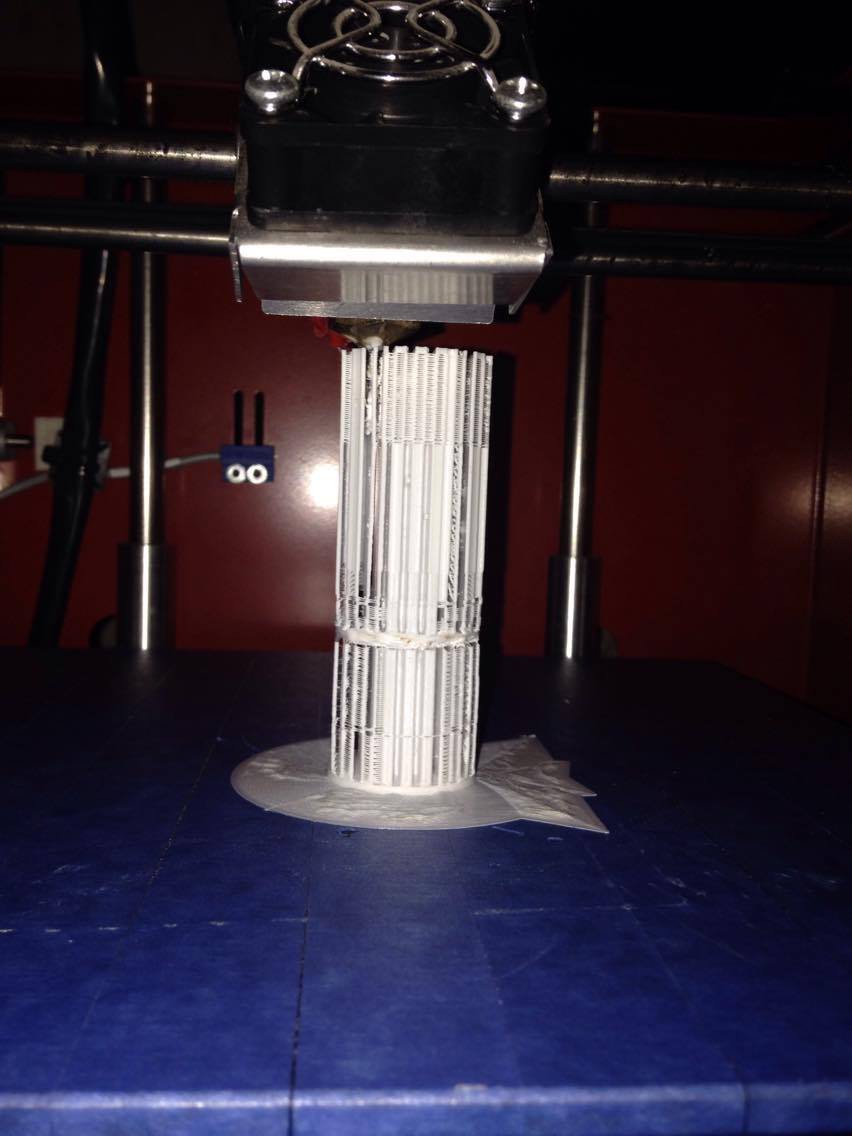

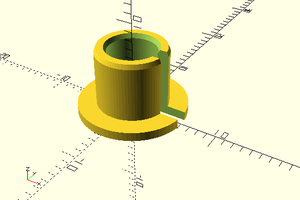

16" barrel- uses an inner barrel with coil stops to assist in coil winding

barrel cover - acrylic (protects electronics)

muzzle - holds barrel cover in place, looks nice, "iron sights"

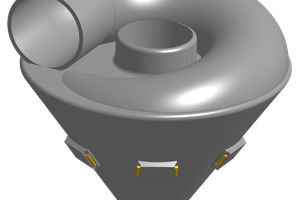

custom upper housing - guides projectile from mag to barrel and had (poor) "iron sights" (actually PLA)

push rod - pushes projectile into first coil since the first coil is forward of the mag (not directly above)

----------

Plan to use super-caps to provide the current to the coils when firing

-circuit will use power mosfets to turn the coils on and off

-mosfet will be triggered by an optical sensor

-rest of electronics is unclear (still building housing)

Peter McCloud

Peter McCloud

johnowhitaker

johnowhitaker

Christian Lerche

Christian Lerche

Aaron P.

Aaron P.