Features are:

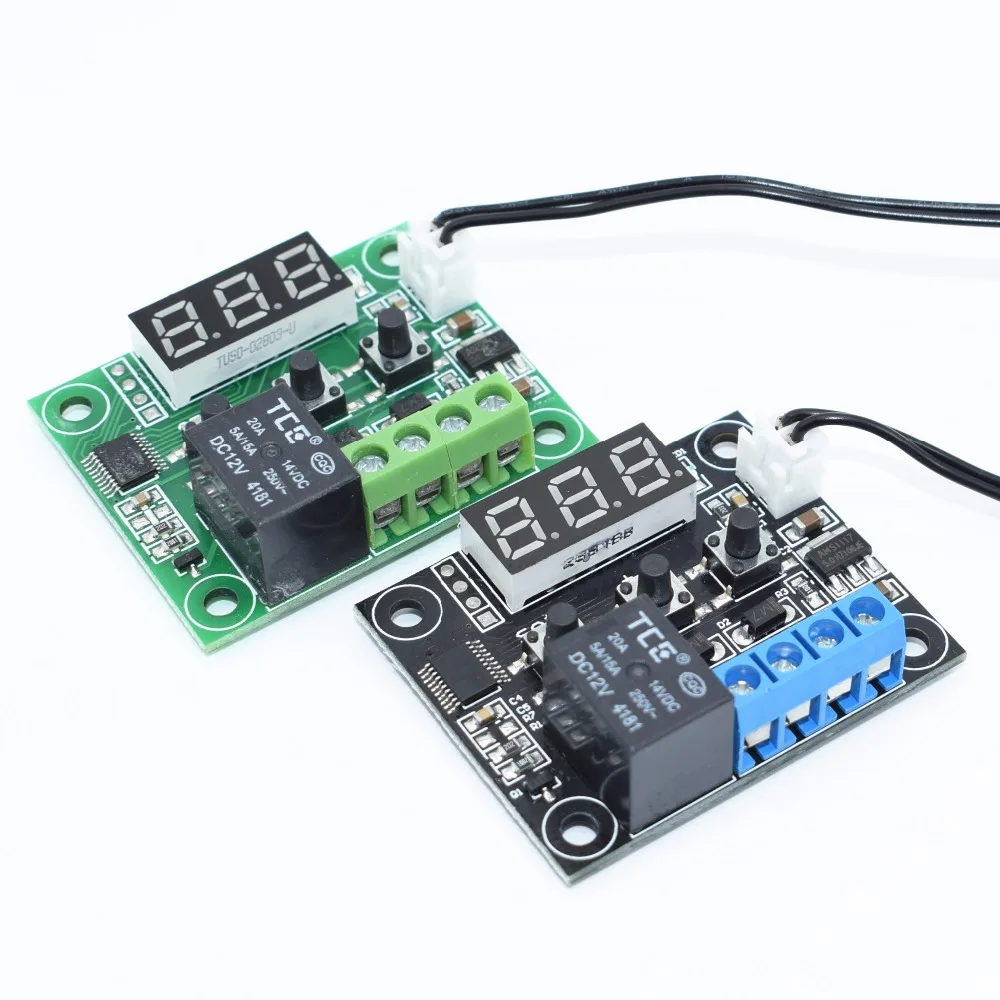

- heating thermostat, e.g. for building a chicken egg incubator

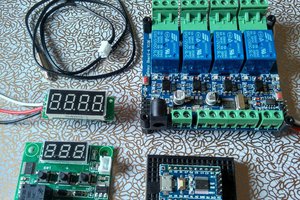

- no special tool installation necessary:

- ready-made binaries, and source code, are provided

- new binaries can be built with the help of Travis-CI

- interactive programming in Forth, even while the thermostat task is running!

- any serial terminal program can be used, e.g. picocom, or cutecom (settings 9600-N-8-1)

- data logger with 6 minutes (0.1h) to 10h interval, and a 144 entry ring-buffer with log access through a serial console:

- Lowest temperature

- Highest temperature

- Heating duty cycle

- Number of relay cycles

- L.dump command prints the log through the serial console - the latest entry is in the last line

- L.wipe command erases the log memory

- basic sensor failure detection

- easy to use parameters menu (no need to search for a manual!) for set-point, hysteresis, and trip-delay

Thomas

Thomas

Check out the

Check out the

Jorj Bauer

Jorj Bauer

Ashwin K Whitchurch

Ashwin K Whitchurch

Got clones with c5 unpopulated FT61E143 and these are factory set wrong. the factory temperature settings are unusable. p1 min 0.1 max 20. p2 min 24 max 120. p3 min -55 max 14, p4 min -10 max 10. p5 min 0.1 max 10 p6 ON OFF. no p7, no p8. the red light does come on on these but the relay does not get triggered at all while red light does light up. Can these be set to 'normal' settings? Will need STM8S003F3 and what to populate c5? How to trigger the relay.

sidenote: have rex100 ac but want to use on 12v battery. what is a good cheap 12v to 220v converting option to use without loosing too much electricity from the battery? It has to last all night. Standard inverter gives up beeping loudly in small hours of night.