To fit inside a bookshelf, the depth of the build has to be under 30cm. On the prototype, it is actually 22cm. It's height is 52cm and the width is 40cm. In operation, the Y-slider moves out up to 6 cm. The X-slider moves +/- 10cm and on the Z-Axis (up/down) it's friggin +/-10cm as well.

The operation zone is designed to hold a standard PCB or printed circuit board by the size of 10x16 cm. A standard perfboard of this size with a raster of 2.54mm holds around 61x39=2379 soldering holes.

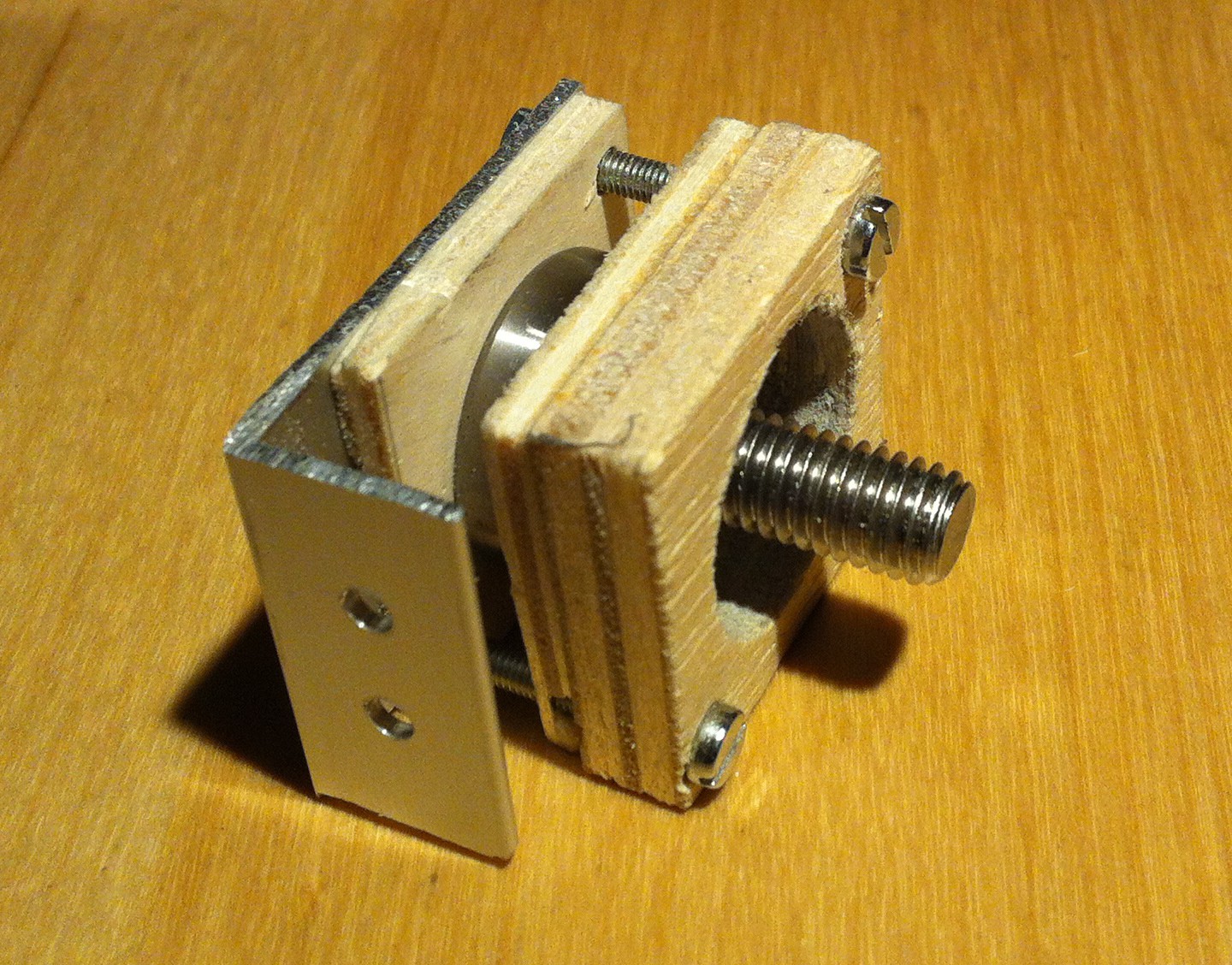

The mount point for tools is made up from two M8 bolts by the vertical distance of 20cm on a socket 6cm wide. This enables tools by the width of up to 20cm as the X-shift is 10cm only. Furthermore, tools can be changed quickly by hand-fastening the M8 nuts.

The axis movements are enabled by so called high torque micro servos which rotate M8 threaded rods, which is by the way a long established and well proven method in the backyard CNC scene, regarding the rods. Regarding the servos I am not so sure, here I guess the stepper motors dominate. Anyway, a servo is much cheaper overall and it gets the job done.

The servo (for example a MG90S clone) at 4.8V applies around insane 1.8Kg/cm torque at a speed of 60°/0.12sec nominal and measured builtin under load (500g) in the backyard around 1Kg/cm at 360°/1.3sec. The M8 gear transfers this into a linear motion, meaning 1.2mm/1.3sec. Therefore, it takes around 173sec to traverse the operational zone in X and 108sec in Y. Roughly estimated, it takes 173x39=6747 seconds or 1h52min to visit all 2379 soldering holes of the perfboard under load. This is a long time. But on the other hand I guess you could never manually solder 2000 connections in 2 hrs anyway.

To control the servos, a ring you need. Which would be casted as esp, raspberry or arduino. I roll the dice and .. it's the arduino nano clone. It has the PWM controllers, ADC and USB on board, which means easy development with the IDE on and powered by a PC. Plus it's cheap.

To fire the servos, I use a 7805 with low drop and 2amps, feeded by an scrap 14V1A transformator.

Ok, sorry for the long post - I finish with the image of a rod bearing mount:

--

--

Regards

Horst Schlawutzke

Horst Schlawutzke

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.