Ok, so things so far have been going exactly as I figured......that is painully slow.

I received the vacuum pump and as luck would have it, it's a total piece of garbage.

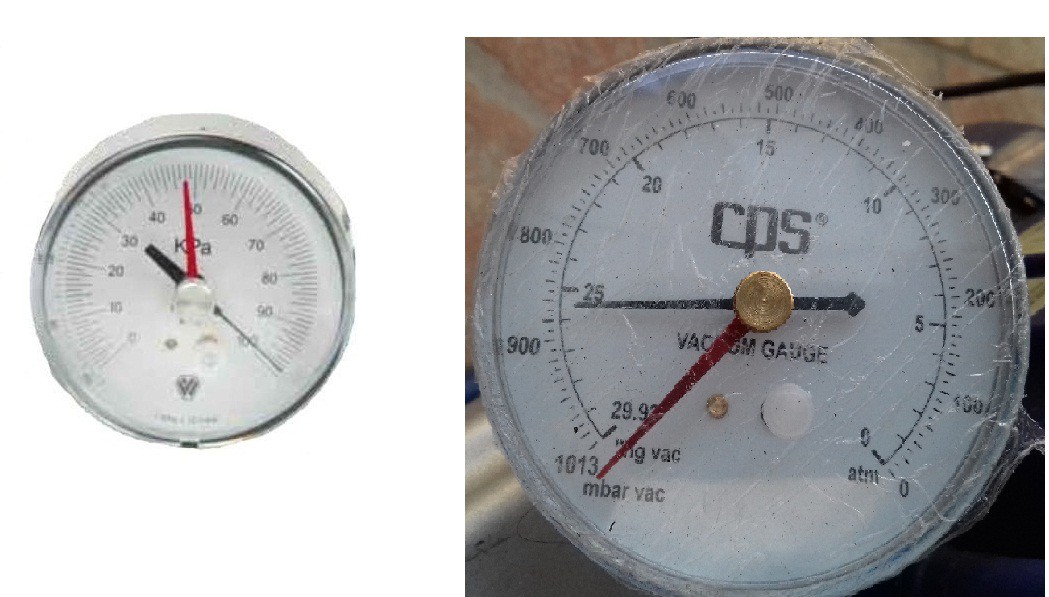

The vacuum gauge on it when it came looke like it had a rough life, so I had to replace it. Turns out that a vacuum gauge witht he correct scale is kind of hard to get in my country. Only 1 or 2 online shops that have it in stock.

This is how the original gauge looked. No glass on it and the indicator needle buggered off to some better place.

This is the pump I got. It's from ITE (german-chineseium grade vacuum pump, from what I can gather from the datasheet) and it's a Blue-Tec MK-60.

Here's the specs on it

So after about a week, the new vacuum gauge came and lowe and behold....it was nothing like the description.

On the left is the gauge from the store's pic. On the right is the very one that I got. But, ignoring my frustration, at least I was closer to testing my pump.

The next thing that got in my way of firing up the pump was a lack of proper fittings. After being delayed 1 week because of my half-arsery and ordering the wrong kind of fitting (Ordered by mistake a 1/8 NPT fitting instead of a 1/4 NPT), when I actually got to order the right one, it never came. No one phoned me to say if they have it in stock or not, no mails, no nothing.

Because my frustration grew eve more, I decided to go at it caveman style and plug the pump's inlet with what I hoped to be and airtight seal made from a small round piece of rubber gasket, wide enought to cover the 1/4 hole of the fitting.

And, of course, when you're on a roll, why stop, right? Turns out that the vacuum pump doesn't go all the way down to the specified vacuum.

I bought some vacuum pump oil and flushed the pump twice (the old oil was OK, but it looked more like motor oil than vacuum pump oil) but still it only went down to about 250 mbar, which is way more that the required 0.05 mbar. Also, the oil that came with the pump had some grime in it, probably because the pump inlet was left open in a shop somewhere.

So, as of now, I either have a leak in the system (probably the rubber is not sealing well) or the pump is actually FUBAR from being run with the wrong kind of oil and/or because of debris still inside it. I can only verify this by actually putting a 1/8 NPT plug on the inlet and running it like that but alas. these seem to be as rare as hen's teeth.

To be continued.....

Razvan Caldararu

Razvan Caldararu

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.