This project to light up my longboard with LEDs was mainly inspired by two things:

Firstly, i put one of my boards under a taxi (actually it was was friends board, which made it worse). Luckily it was only the board and not myself. On reflection of this incident, all i could say for certain was, if there had been lights on the board the driver of the car would have definitely seen me. ( On a side note, my Shark Wheels survived the encounter.. kudos. )

I really liked that board.

Secondly, I saw two projects whilst browsing the internet, both were attempts to track the wheel position on a skateboard and match it to the LEDs running down the board. That was such a cool visual trick, i really wanted to try it.

http://www.instructables.com/id/Ground-Tracking-LED-Longboard-Mod/

https://softsolder.com/2012/08/29/longboard-speed-sensing-ground-effect-lighting/

Both of these things happened in the same week and as i had some spare LED strip i though i would have a go.

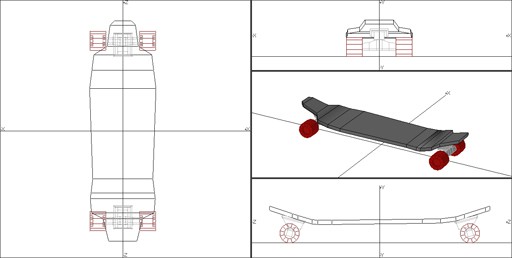

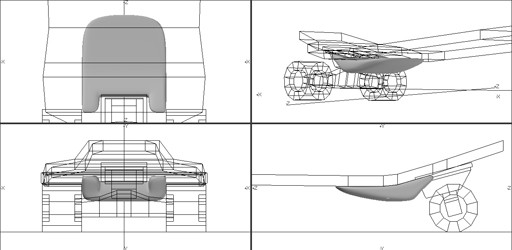

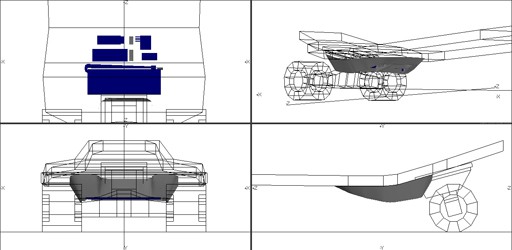

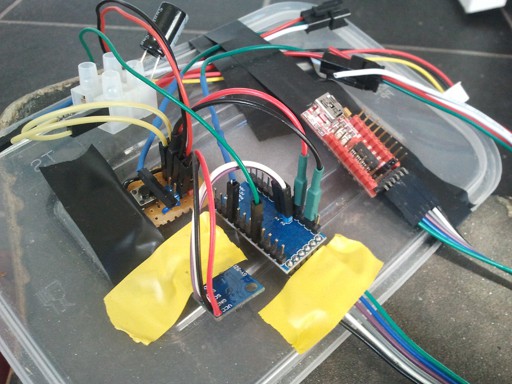

The rough concept which was then worked out involved battery power, a microcontroller, buttons, LED strips, sensors on wheels and a sensor to tell the orientation of the board. Based on this i then roughed out a set of modes which could be mixed and matched, mabye with animations as go-betweens.

- Front/Rear lights. For safety so we can be seen when riding at night. Fade on when the board is placed horizontal.

- Turning indicator lights. Utilising sensors we can detect when the board turns a corner and blink the direction. Avaliable when the board is horiontal.

- Stood vertical. Utilising sensors we can tell when the board is stood up. We then fade the LEDs to the bottom with an animation, then, if not turned off by the switch, the board will 'breathe'. (My main board has a unique feature, the rear of the board is in line with the wheels, meaning it can stand up by itself, very handy.)

- Stood vertical (upside down). This will be dependent on whether the board in case has mirrored ends or a definite front and back. Most probably this will just be the inverse of 'stood vertical'. The only difference being the direction of the interceding animation.

- Stood on it's side (either). This could be used for portable lighting, or as an emergency feature should you lose control of your board.

- Breathing. The bottom few LEDs on the board will gently pulse a glow at 12 times a minute (average breathing time when sleeping?).

- Horizontal underlights. Eventually many modes will be available when riding your board, from full colour flood, through blinks, to ground tracking patterns. For my purposes i only require a few, plus effects, as i will be just cruising around.

- Full colour. Variable brightness and full RGB colour range.

- Full colour with fade towards direction of inertia. eg. Skate forward and the light bunches up to the front and fades slight towards the rear. When you stop your board the light moves to the back of the board and the red tail lights get brighter. It will do this all at roughly the same speed as you do.

- Ground tracking. Using our sensors we can tell exactly how the board is moving. this enables us to pull a visual trick.The simple version is to light up one LED on either side of the board, in the middle. Then, when the board moves, we move the light in the opposite direction at the same speed. This has the effect of making the light stay in the same position. This effect works better the more LEDs there are per meter. This one LED effect can then be expanded into patterns scrolling down the side of the board, except it looks like the patterns stay still, as the board moves. One mode could have repeating stripes the same length as the strips on the road. Another could track the road markings themselves if you skated down the middle of the road and turn the lights on to match.

matt thurstan

matt thurstan

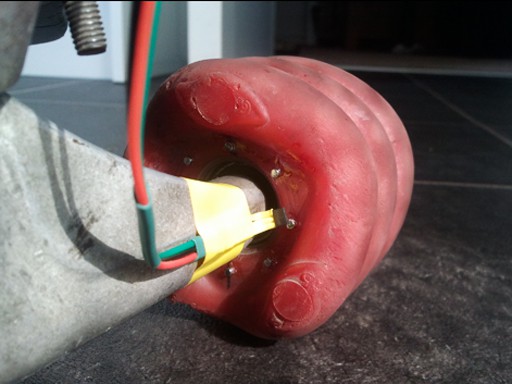

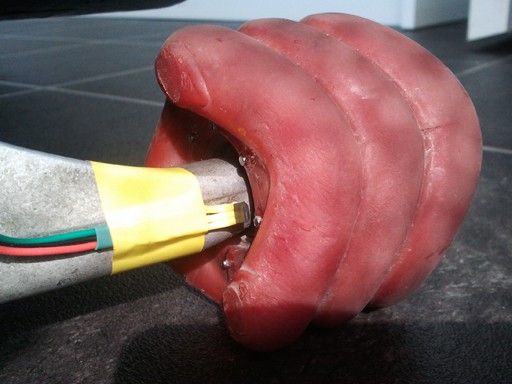

Close-up of magnets glued onto a crazy Shark Wheel.

Close-up of magnets glued onto a crazy Shark Wheel.

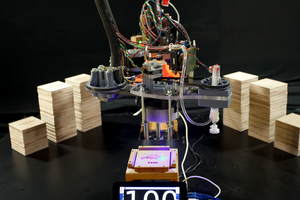

With 40 LEDs this will give us about 2 hours use if all the LEDs are turned on at full-brightness. As the LEDs won't be on all the time, this lengthens the usage, add in some other tricks like duty-cycle reduction in the programming and we should end up with a 4-5 hours continuous maximum usage scenario. But, given the likelihood of NOT skating around with all lights constantly flashing at full brightness in convoluted patterns that give bystanders epilipsy, i am optimistic in hoping for at least 10 hours use between charges.

With 40 LEDs this will give us about 2 hours use if all the LEDs are turned on at full-brightness. As the LEDs won't be on all the time, this lengthens the usage, add in some other tricks like duty-cycle reduction in the programming and we should end up with a 4-5 hours continuous maximum usage scenario. But, given the likelihood of NOT skating around with all lights constantly flashing at full brightness in convoluted patterns that give bystanders epilipsy, i am optimistic in hoping for at least 10 hours use between charges.

Andy Smith

Andy Smith

anfroholic

anfroholic

maehem

maehem

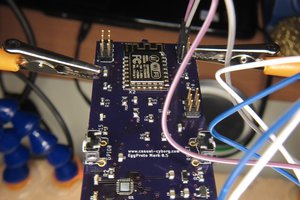

Casual Cyborg

Casual Cyborg