Today I went to print the new end effector.

First off, I had left the Zip-lock bag open in which I keep my top secret absolutely fabulous nylon filament. Given I'm currently in Florida, that was a really bad choice and the filament was unusable until I dried it out. A couple hours in and out of an electric oven set on low and the moisture level was back to a printable level.

Pretty cool little hygrometer eh. Lasts 6 months on a single rechargeable AA.

So I heated up the print head to 240C and went to swap in a shiny new nozzle. When I screwed the new one in it just kept turning and turning... The old one fit nice and tight when I took it out. Tried to put the old one back in and it started to tighten up, then it stripped also.

<insert expletives here>

So I got out my micrometer and measured the threads on another one of my 'new' nozzles. The threads on this thing were a full 0.6mm smaller diameter than they should have been.

I guess that's what you get when buying 14 nozzles for $8 with free 2 day shipping. Complete crap.

So my quest to save a buck has ended up costing me part of a custom machined prototype print head.

Removed the mixing chamber, took it out to the garage, and pounded on it with a hammer until the AL mushroomed in enough to allow me to cut a new thread. ONE new thread.

Wet sanded the sealing surface back to being flat, reassembled it, and gingerly put one of the largest thread diameter new nozzles in the printer. It was marked as a 0.4mm nozzle. Measured the resulting extrusion as 0.56mm. Again... Complete crap.

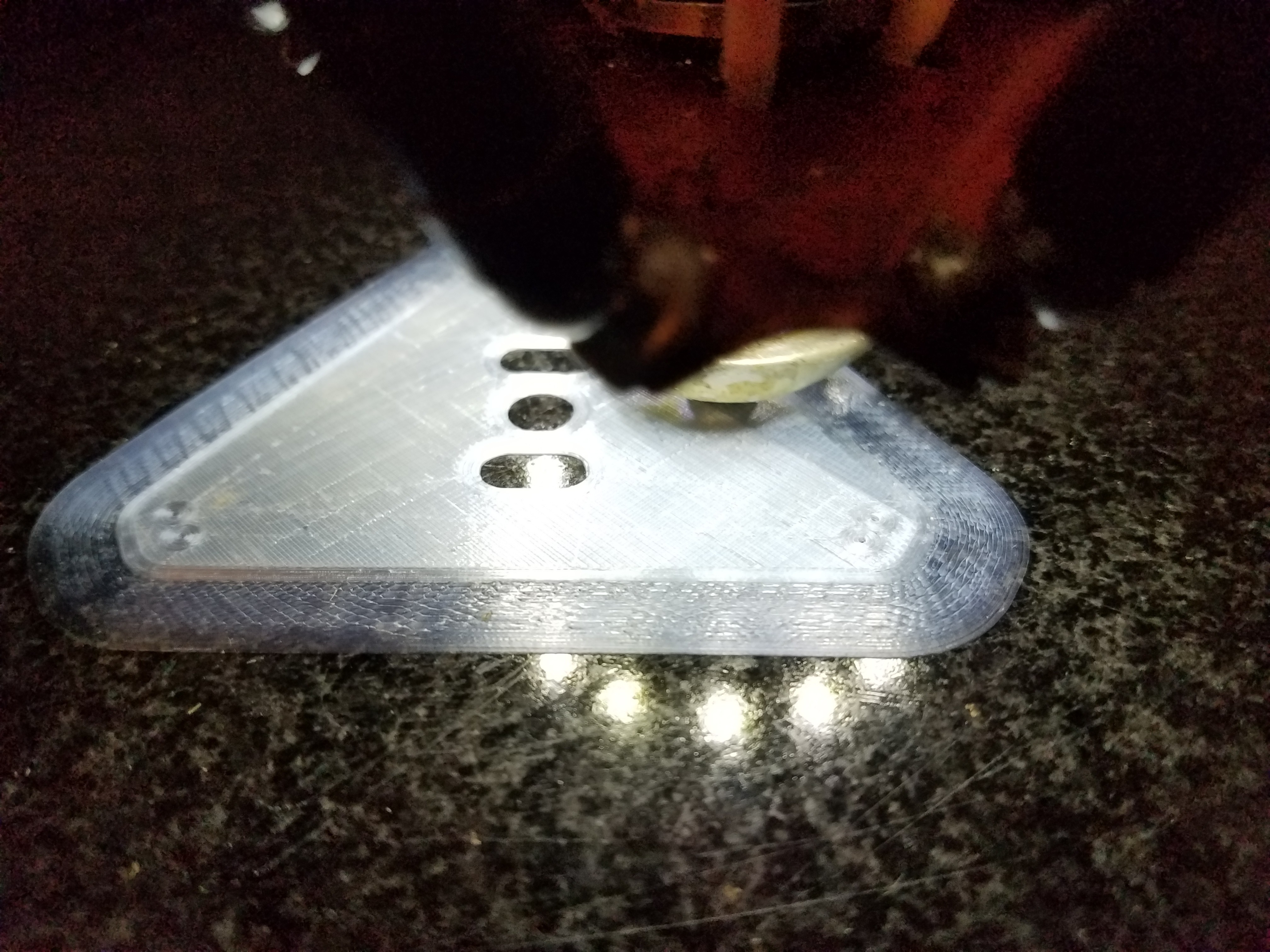

So I re-sliced the object in Cura to match my now colossal extrusion diameter, and it is now printing......really......slowly....

EDIT: The nozzle popped out again so that chamber is toast, but I had a spare mixing chamber from an older version of the print head which fit.

Back to printing again, and I'll never buy cheap nozzles again.

Daren Schwenke

Daren Schwenke

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Tried that, and using aluminum foil. There was additional flailing which occurred which I did not document, but at least it's back to printing now. Lesson learned, moving on.

Are you sure? yes | no

May be Teflon tape used for sealing water fittings can be used to keep the nozzle in.

Are you sure? yes | no