A couple months back I split the heated bed on my other printer. My fault. Nema23 steppers, machined aluminum/steel rails, and 9mm belts ensured I could supply enough force to split it.

Since my table saw is 1500 miles away currently, this makes creating a replacement difficult. That and the ceramic tiles I've found locally all suck. 'Polished' is apparently a relative thing as they have a nice wavy reflection, aka, not flat. Guess I got lucky with my first couple tiles.

So, I've been making do with a smaller granite floor tile as they are basically perfectly flat and in stock at Home Depot. I pre-heat it in the toaster oven, drop it in, give it a spray with Aquanet, and print.

That works pretty well for nylon, PLA, TPU, and small ABS parts. Large ABS parts warp off the bed when the tile starts to cool down so it's basically a matter of how fast I can print.

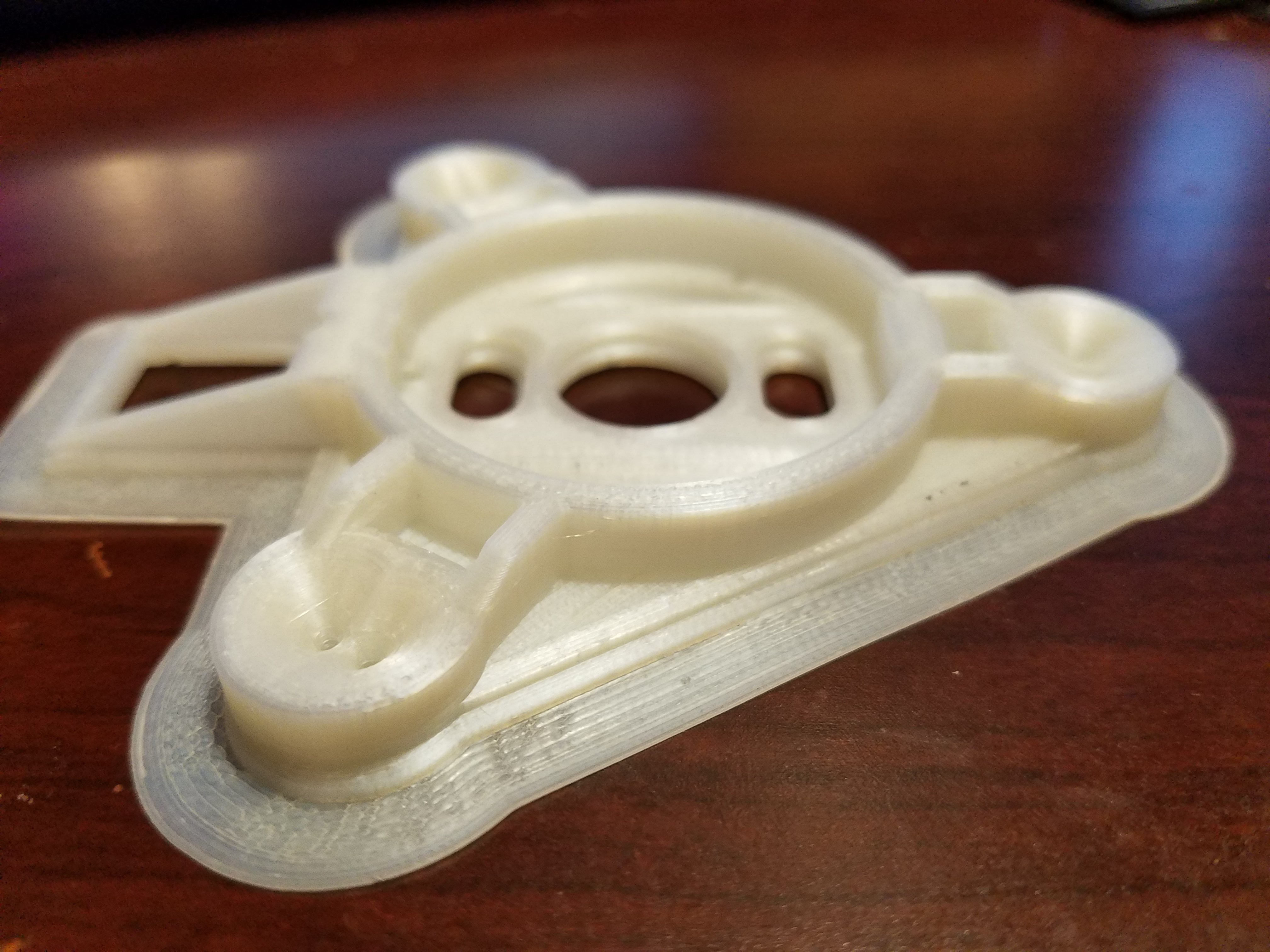

I increased the thickness of basically everything on the last version of the end effector, so now I can't print it fast enough in ABS.

Tried it in nylon.

The print head must have snagged on something (100% infill and a little over-extrusion for strength), so the tile moved during the print. This resulted in the ledge/offset you can see on the base. Good news is it feels stiff enough to work when printed in nylon now.

Trying again.

EDIT: and again... and again..

I had to turn on Z Seam Alignment: Random as Cura kept putting the seam in the same spot on an inside corner which was resulting in significant over-extrusion in that one area. So the material would build up there and eventually knock the print loose during a travel.

One more try.

Daren Schwenke

Daren Schwenke

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.