System overview:

As you can see in the gallery, here's a set of metal parts with a smattering of mounting holes. All of which enable convenient mounting of Arduino-format boards, plus my own DINuino-format prototyping boards and related custom designs.

They can be packaged "open-frame" by utilizing just the L-shaped DIN mounting plate.

You can also attach the 3 cover pieces to create a fully enclosed device.

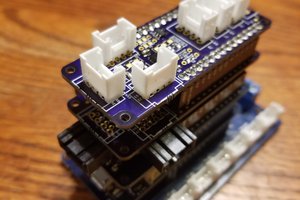

My first DINuino prototyping board (shown) offers a place to plug in an Arduino (UNO to MEGA sized) CPU module. A standard 0.1" grid of holes can be utilized for your custom circuitry. You can find more on this prototyping board in its own project area.

DIN-Uino Mounting Plate:

* Base-plate can be used for open-frame project, but it is designed to accept a cover so you can create a fully-enclosed project.

* Intended primarily for projects that use the DIN-Uino carrier board.

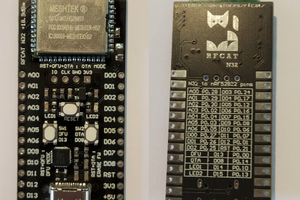

* Can also be used with Arduino-compatible hardware alone. In this case, the Arduino "CPU" module would mount directly to the base-plate. There are numerous holes that allow you to mount the "CPU" either face-up or face-down. Use standard M3 (or #4-40) hardware/spacers/etc.

* 1/16" thick aluminum (all metal parts are the same thickness).

* Features a mounting-foot: After clipping your module to a DIN-rail, this foot allows you to firmly affix (and ground!) your module to the mounting plate.

* DIN-rail clip: Metal, spring-loaded. Standard catalog item from Hammond Mfg. This clip does NOT need a tool, just push down swing away from the DIN-rail. Remove the mounting-foot screw first of course - if you're using that feature.

Cover:

The cover plate normally would come blank (for your own custom application). As shown, it is configured to fit with the DINuino-MEGA-B prototyping board, thus allowing access to the power-input, LEDs, and Phoenix connectors.

Side-plates:

These plate are designed to be symmetrical - they can be used on the left or right side. However, the configuration shown in the gallery - has the left side plate with a couple of connector holes - which line up with the power and USB connector on a typical Arduino-Mega-2560 board. Of course, for your custom applications - cut your own holes into blank plates!

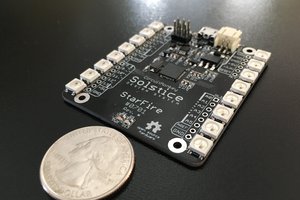

DIN enclosure size:

The current set of cover+sideplates are designed to implement a 42mm wide DIN module. However, a taller cover (and taller sideplates) can easily be designed to make larger enclosures. The base-plate always remains the same.

Alastair Young

Alastair Young

OzQube

OzQube

Nikolaj Andersson Nielsen

Nikolaj Andersson Nielsen

maehem

maehem