This log describes the design of the hand chassis, and the mechanical transmission system. The electronic circuitry and sensor modalities will be discussed in a later entry.

Design Considerations

I chose to go with a five finger anthropomorphic hand design as opposed to some sort of two or three finger gripper for the following reasons:

- to enable the hand to grasp a range of different objects. The human hand has specialised itself over time to become the perfect multi-purpose tool, allowing for a wide range of different grasps, such as pinch, wrap, circular grasp. See the below chart for details [1].

- to address my original motivation of researching prosthetics, a human hand design makes the most sense.

- to utilise open source materials available on anthropomorphic hand designs. Although I designed my prototype from scratch, there is a vast pool of inspiration to be taken from fantastic projects such as Gael Langevin's InMoov hand [2] or OpenBionics [3].

The Hand Chassis and Tendon-Based Transmission System

All parts for the hand were designed in Autodesk Fusion 360 (freely available for students!) and printed in PLA plastic.

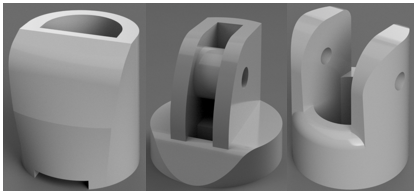

All fingers consist of the same base parts (see below), only the base of the male and female part changes size according to the length of the specific phalanx.

Phalanges are connected with joints rotating around 2mm metal rod. The finger assembly was tested on a printed finger base:

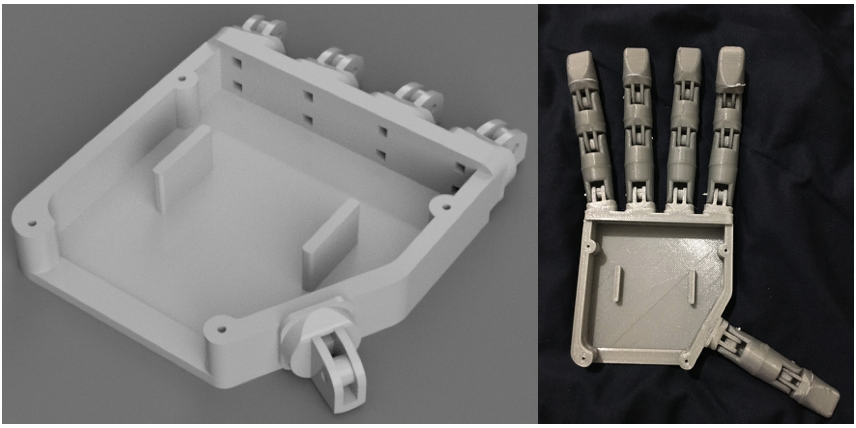

Next, a palm was designed with five male finger parts as the base for each finger and the thumb. The initial palm design was supposed to house the camera before it was moved to the wrist, hence there are guides for the Bowden system and space for the camera inside the palm.

I went on the print and assemble the first hand prototype:

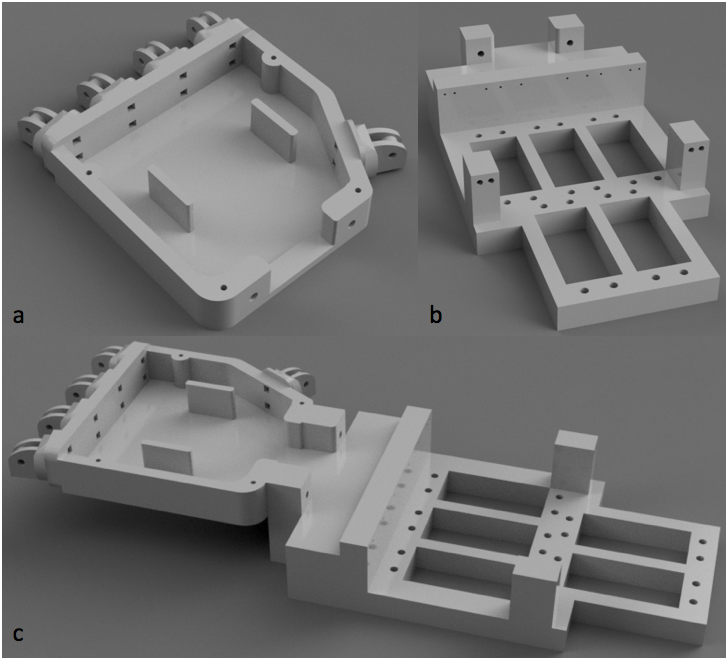

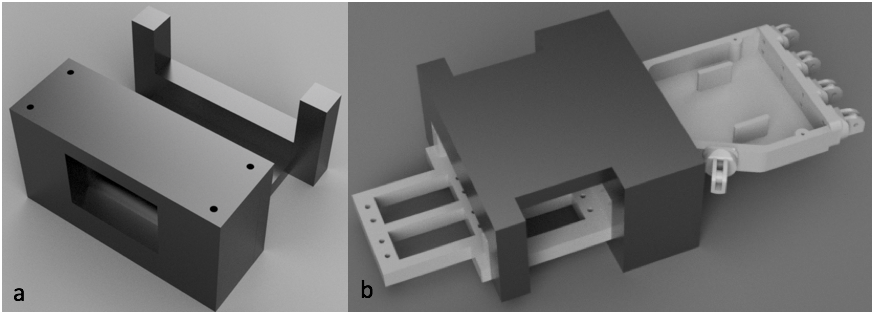

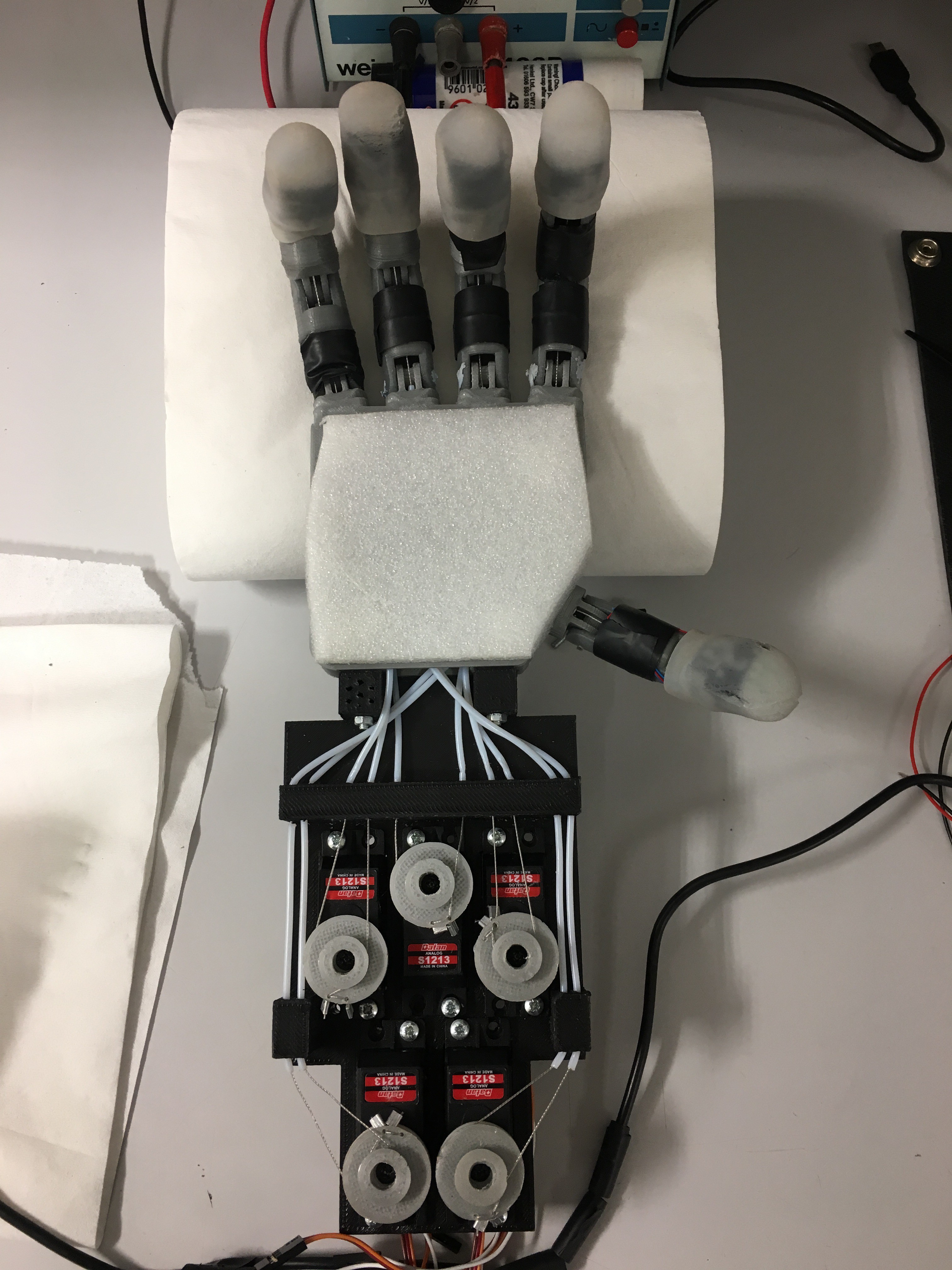

Once the first hand was printed it needed to be actuated using five servo motors. The five servos are housed in a servo bed with guides which lead the tendons from the palm to the servos. The tendons are mounted onto each servo horn using two servo rings of different sizes, as I found this gives the maximum turn with minimum backlash. This is due to the way the fingers bend the opposing tendons don’t expand and contract by the same amount. The palm design needed to be altered at the wrist to allow for two M3 bolts to connect the palm to the servo bed. Here are some renderings of the altered palm design(a) and the servo bed (b), as well as their assembly.

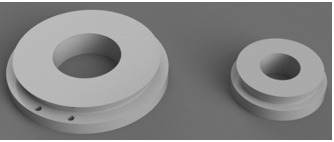

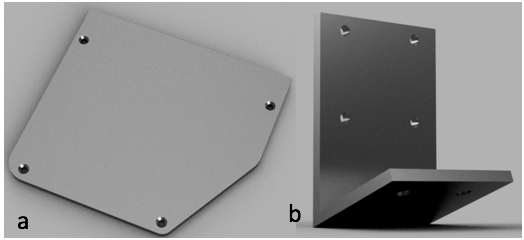

These are the servo rings used to connect each tendon to its servo:

To complete the actuation and transmission part of the hand, two tendons were run through each finger, for extension and contraction respectively. The tendons run out of each finger into a Bowden system, through the palm and out through the wrist into the servo bed to their respective servo motors.

The tendons itself are 0.5mm closed loop wire which is normally used for transmission in model aircrafts. The wire was crimped to the servo rings using 0.5mm diameter aluminium ferrules.

The Bowden system was built using 1mm inner diameter/2mm outer diameter PTFE tubing.

To be able to use the hand prototype in different positions I designed a cover for the servo bed that allows for the hand to be placed on its side, facing up, or facing down. This provides flexibility for using the hand in different settings and makes the actuation system less prone to damage. Please note that in order for the thumb to move freely you need to saw off the right corner of the cover (I haven't gotten round to changing the STL file, sorry).

After testing the assembled hand, it became apparent that embedding the camera into the palm was impractical, and it was moved onto the servo bed cover instead. For this a mounting bracket (b) was designed and the palm covered with a lid (a):

The overall design was refined by adding a soft silicone coating to each fingertip (toe cap protectors believe it or not) and an 8mm thick foam sheet onto the lid of the palm to provide more grip and dexterity.

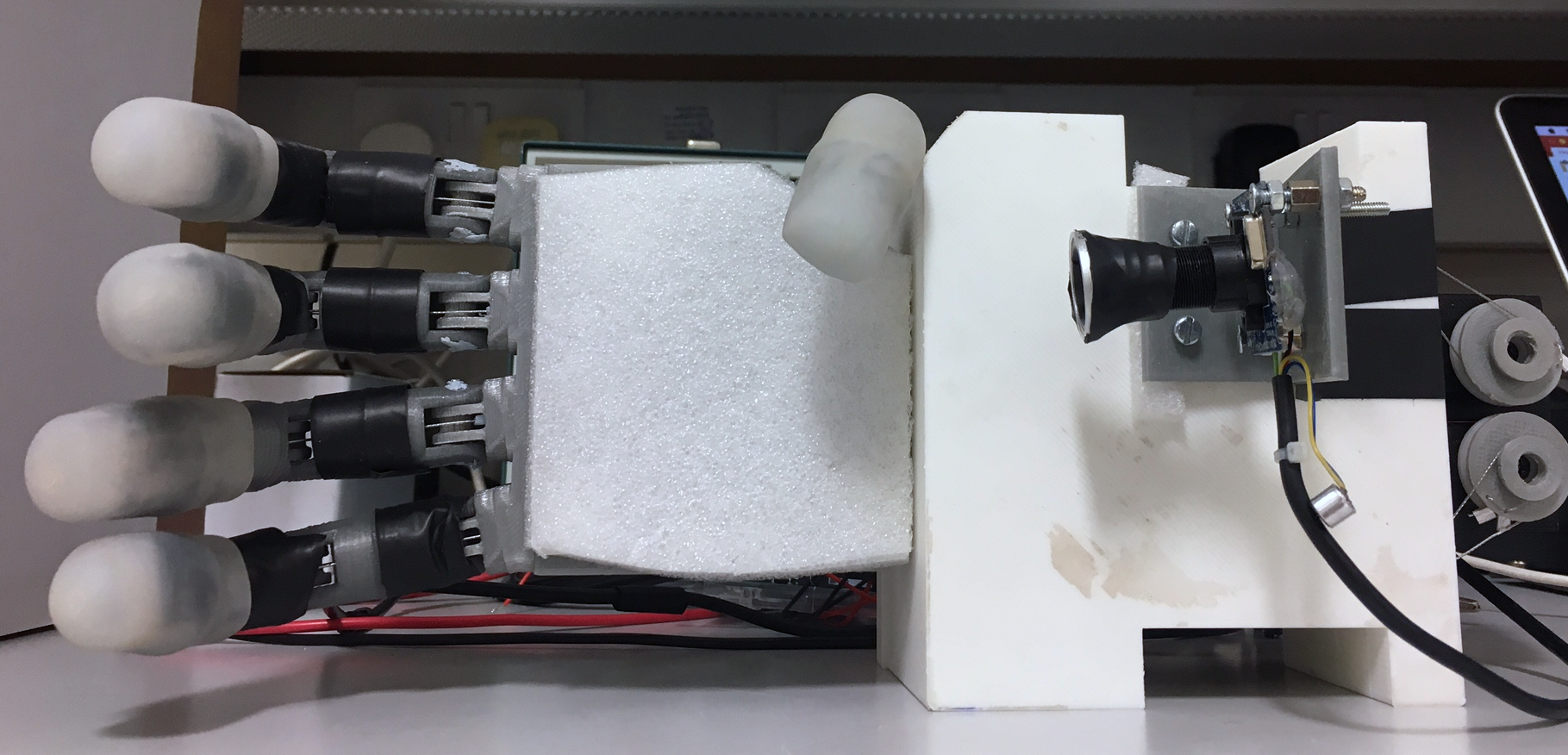

Here is a photo of the current assembly:

Here you can see the assembly with the servo cover removed:

In the next log I will cover the electronic circuitry as well as the low-level API I wrote, bringing the hand to life.

STL files for all parts are available to download under files.

-

M. R. Cutovksy, “On Grasp Choice, Grasp Models, and the Design of Hands for Manufacturing Tasks,”

IEEE Transactions on Robotics and Automation, vol. 5, no. 3, pp. 269-279, 1989.

“Open Bionics,” Open Bionics, 2016. [Online]. Available: https://www.openbionics.com/about/.

G. Langevin, “InMoov: Hand and Forearm,” InMoov, 2016. [Online]. Available: https://inmoov.fr/hand-

and-forarm/.

Stephanie Stoll

Stephanie Stoll

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.