Based on the design concepts from the Concept Development phase of the grant, a test fixture prototype was designed and fabricated. For cost efficiency, the text fixture had enough pins (147 pins in a 7x21 array) to demonstrate graphical and textual output while conserving development capital for additional materials testing and iteration of design. Performance and function were prioritized over screen size.

The text fixture was designed to assess performance of a range of potential components and over a range of demands. Prior to a technical design, systematic experiments were organized that could test hypotheses that were critical to answer prior to an expensive scaling of the design for full scale prototyping and testing.

Software to control the components was developed. The software allowed for components to be tested over a wide range of their performance capabilities and in various combinations.

A test fixture was built and tested. Material selection for components was found to be a critical factor in the success or failure of the system (based on the PFMEA. As such, a wider range of materials were tested. Mechanical systems failed and new component designs were created and also tested in the test fixture. Through testing, materials selection was narrowed to a set of materials and materials configurations that provide optimal functioning in a cost effective form. Mechanical systems were refined to a state of reliability and performance that matched the success criteria for the development stage.

The final test fixture was demonstrated to the blind singer Andrea Bocelli who requested the first unit from the assembly line.

Videos of the system functioning, or in person demonstrations are available with a CDA in place.

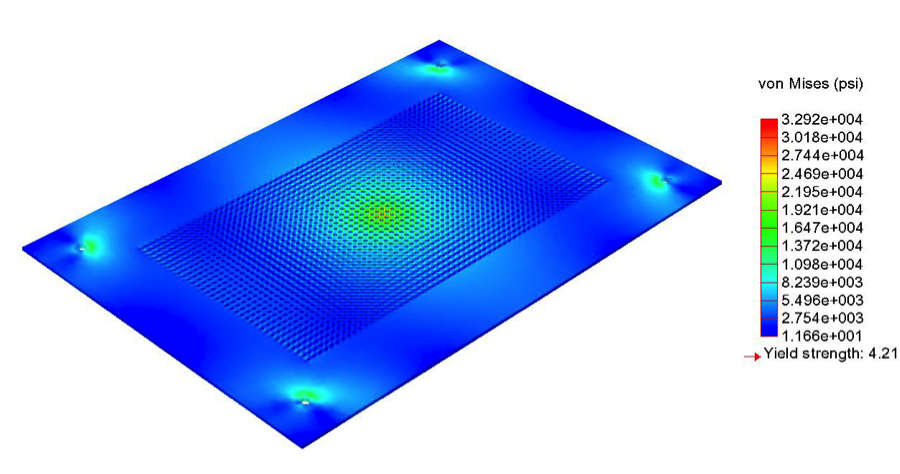

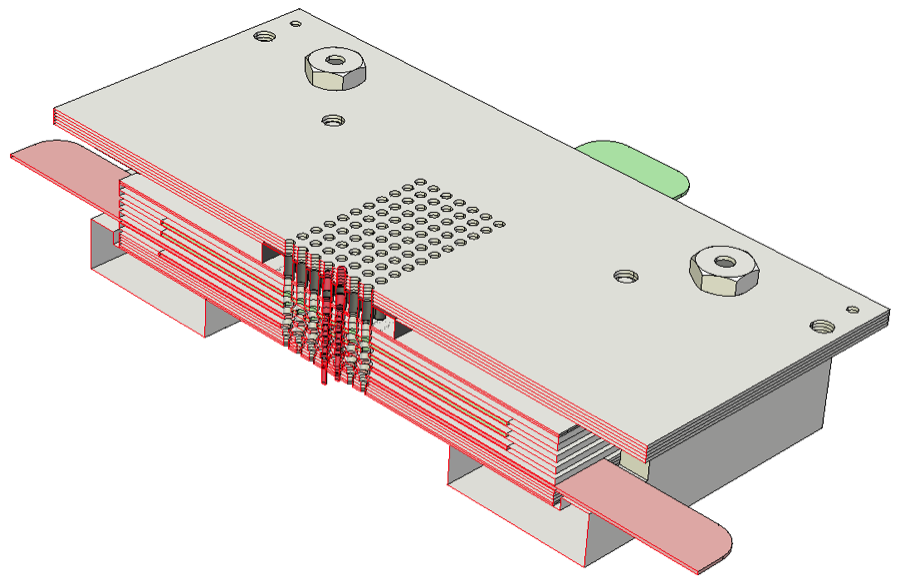

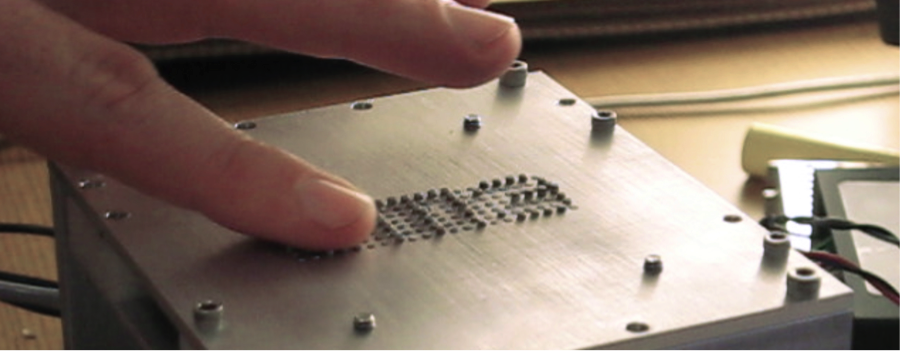

Images shown are:

1. Finite Element Analysis of possible material tested for use as a top touch plate under pressure.

2. CAD cut aways of the internal components of the tactile pins and holding plates.

3. A photograph from the demonstration video on the prototype.

4. One of the Swiss turned pins used in prototyping.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.