Please lay on the couch and try to remember your earliest electro/nic experience. For 10% of you, from the haze of time, slowly should emerge some sort of power source and ... if you are old it was probably light bulb or motor, for my generation we talking about high power led. Those of you with light bulb were lucky - they self regulate its current, so you get nice warm light. With my led I was pleased with local equivalent of Betelgeuse and nice cloud of something, what once was p-n junction.

For the second attempt i was equipped with resistor. It worked, there was light, i was happy and ohm law ignorant. It was also that time when i learned about power dissipation and thermo receptor pain threshold when I touched that ressistor. Fastforward to present time, we will use all that experience do make something useful.

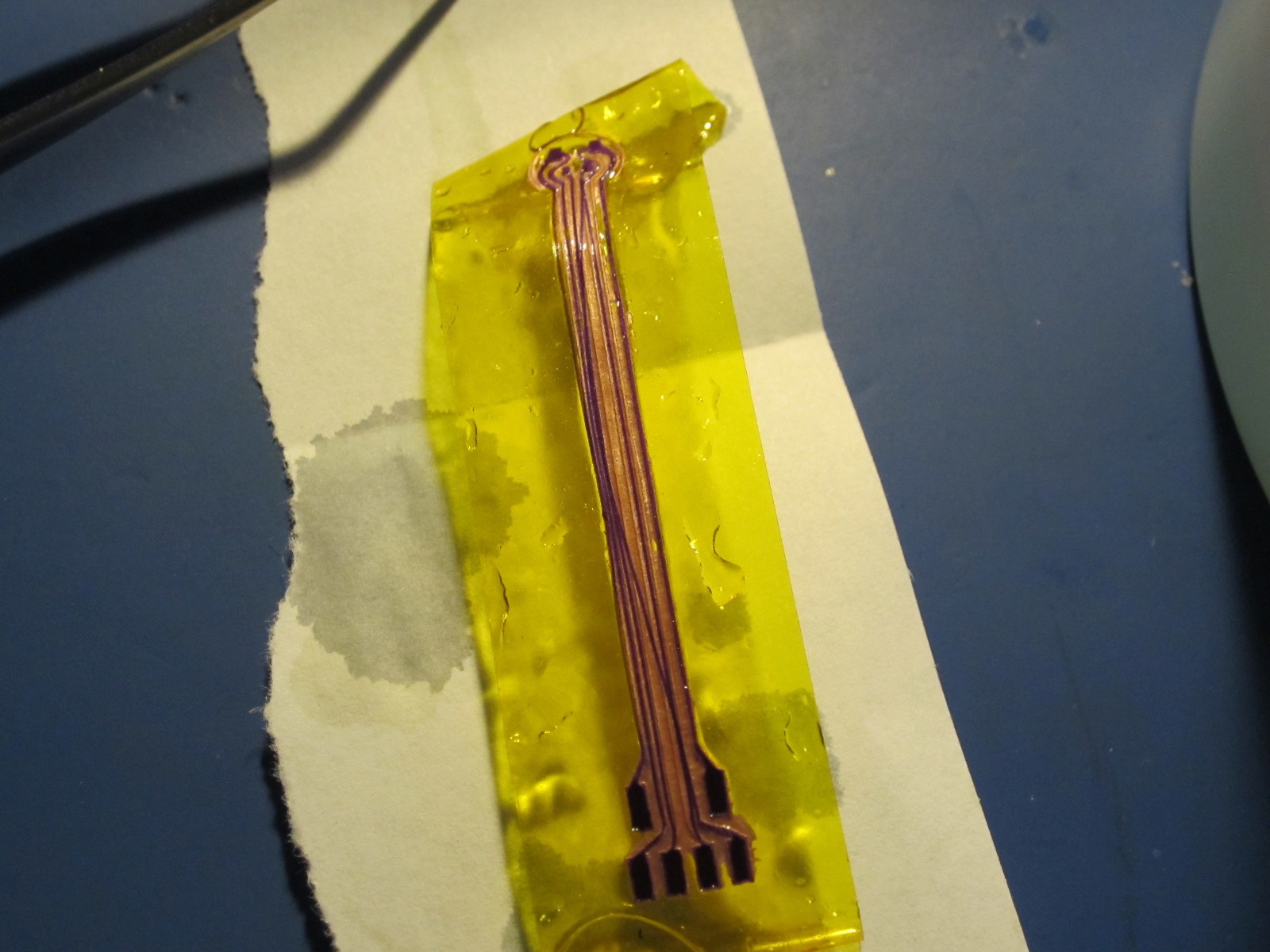

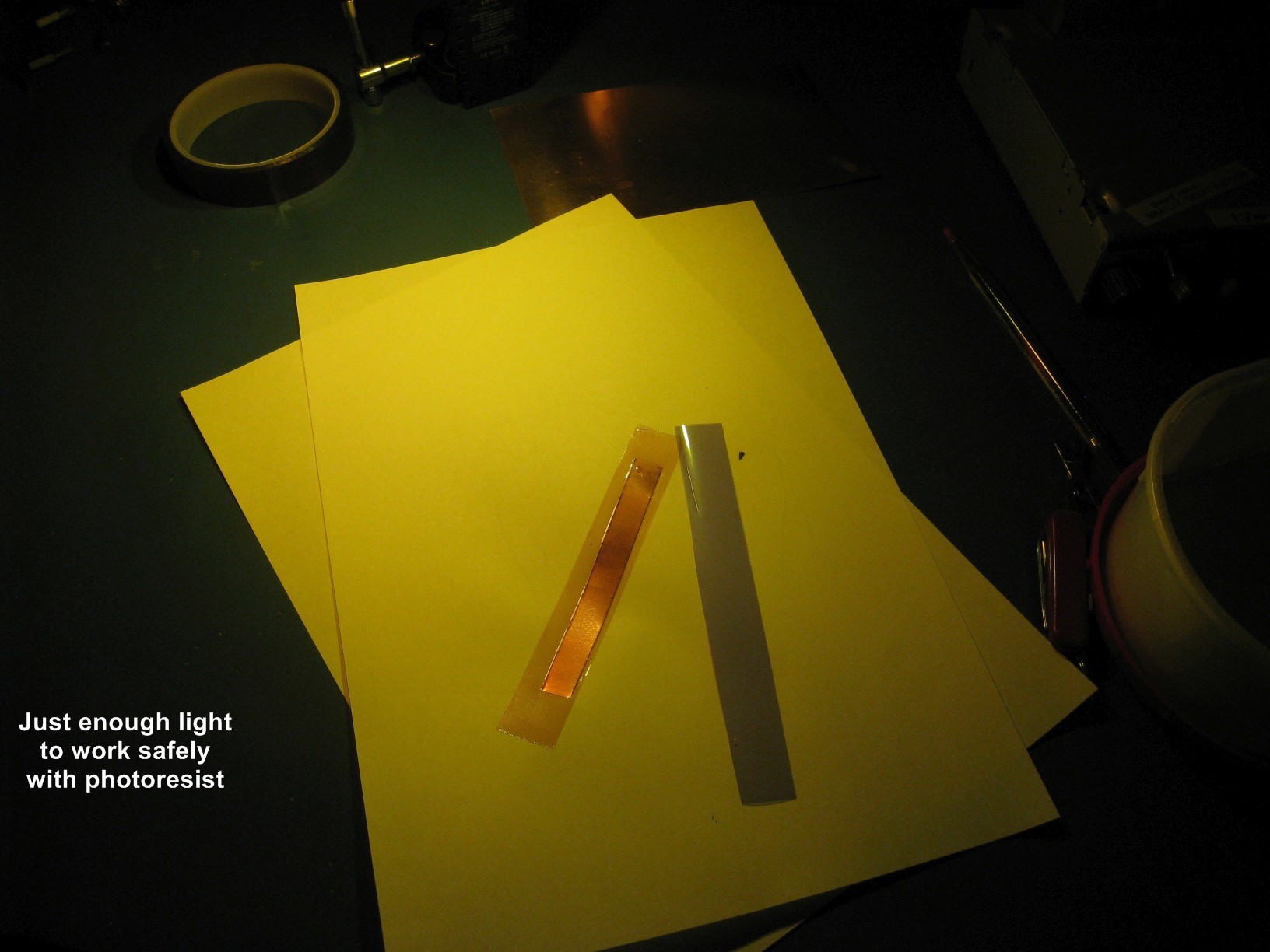

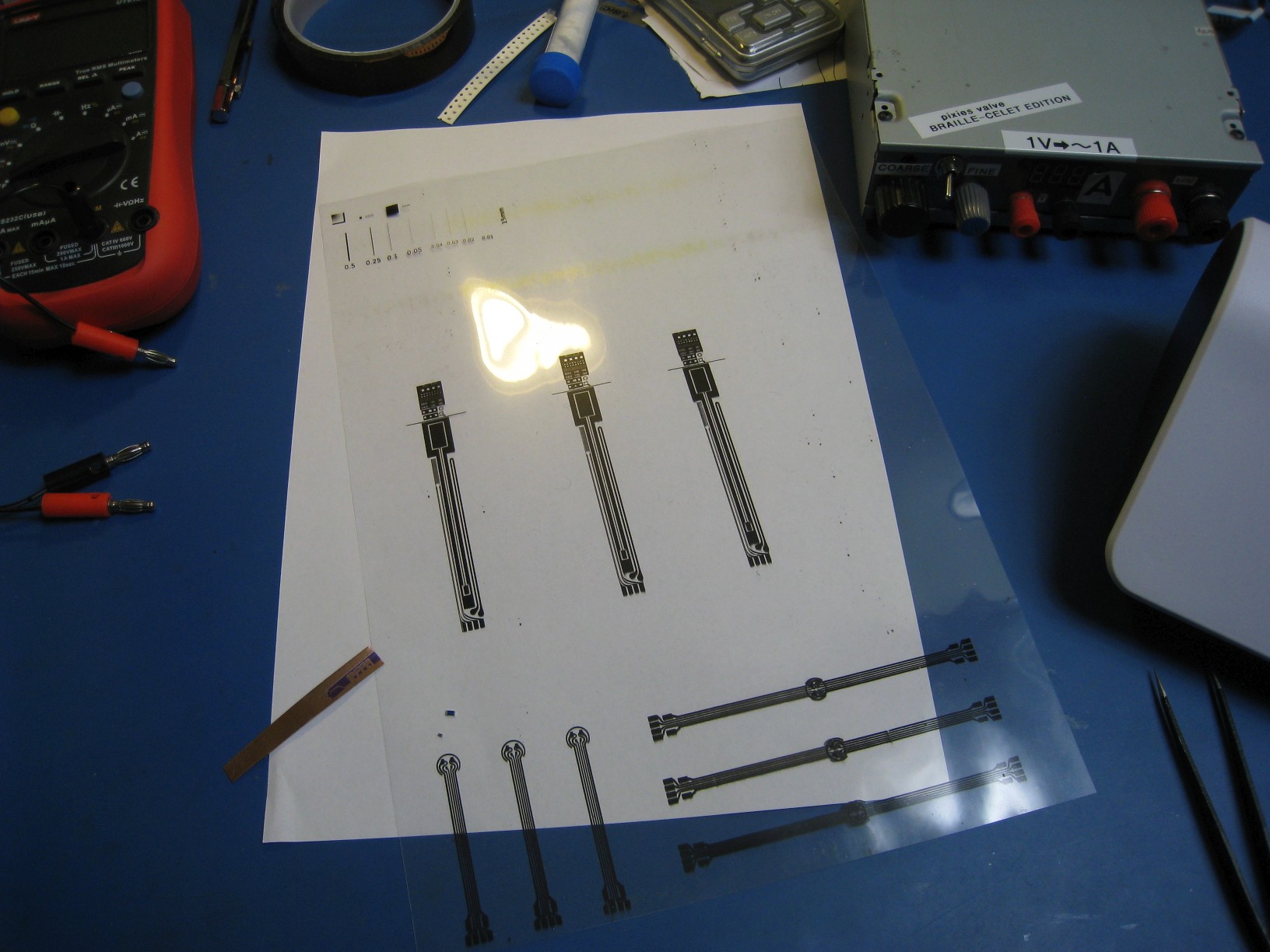

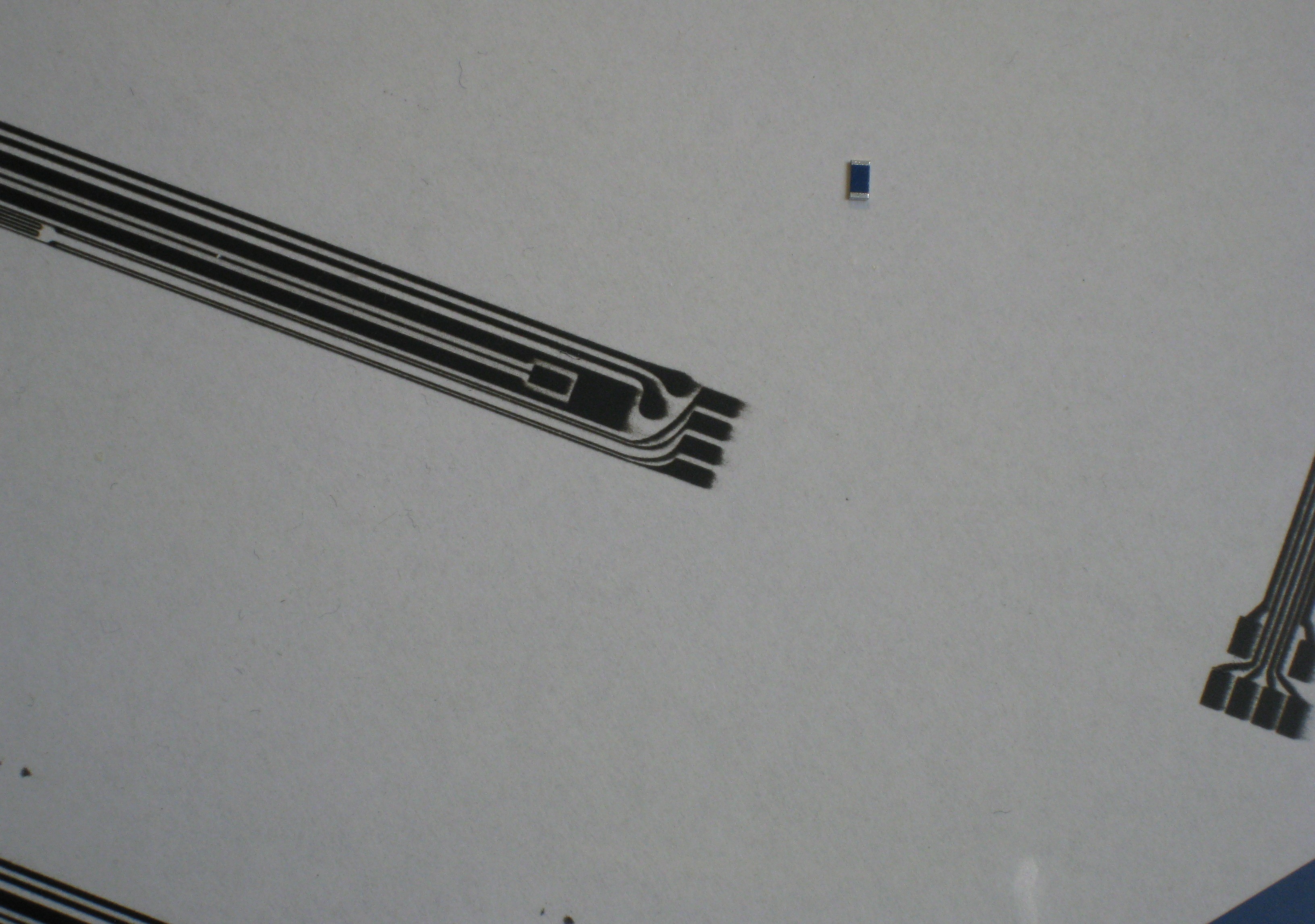

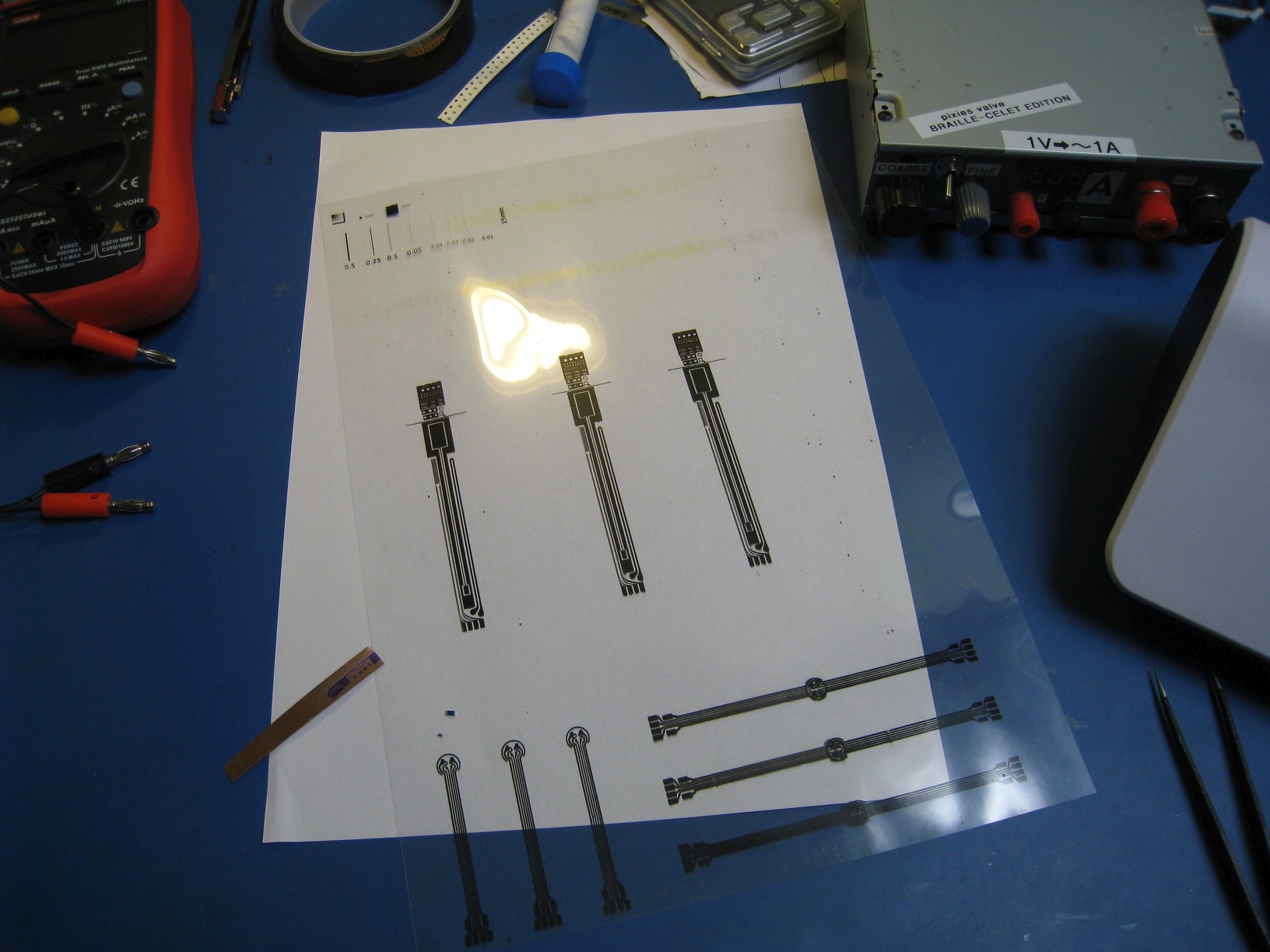

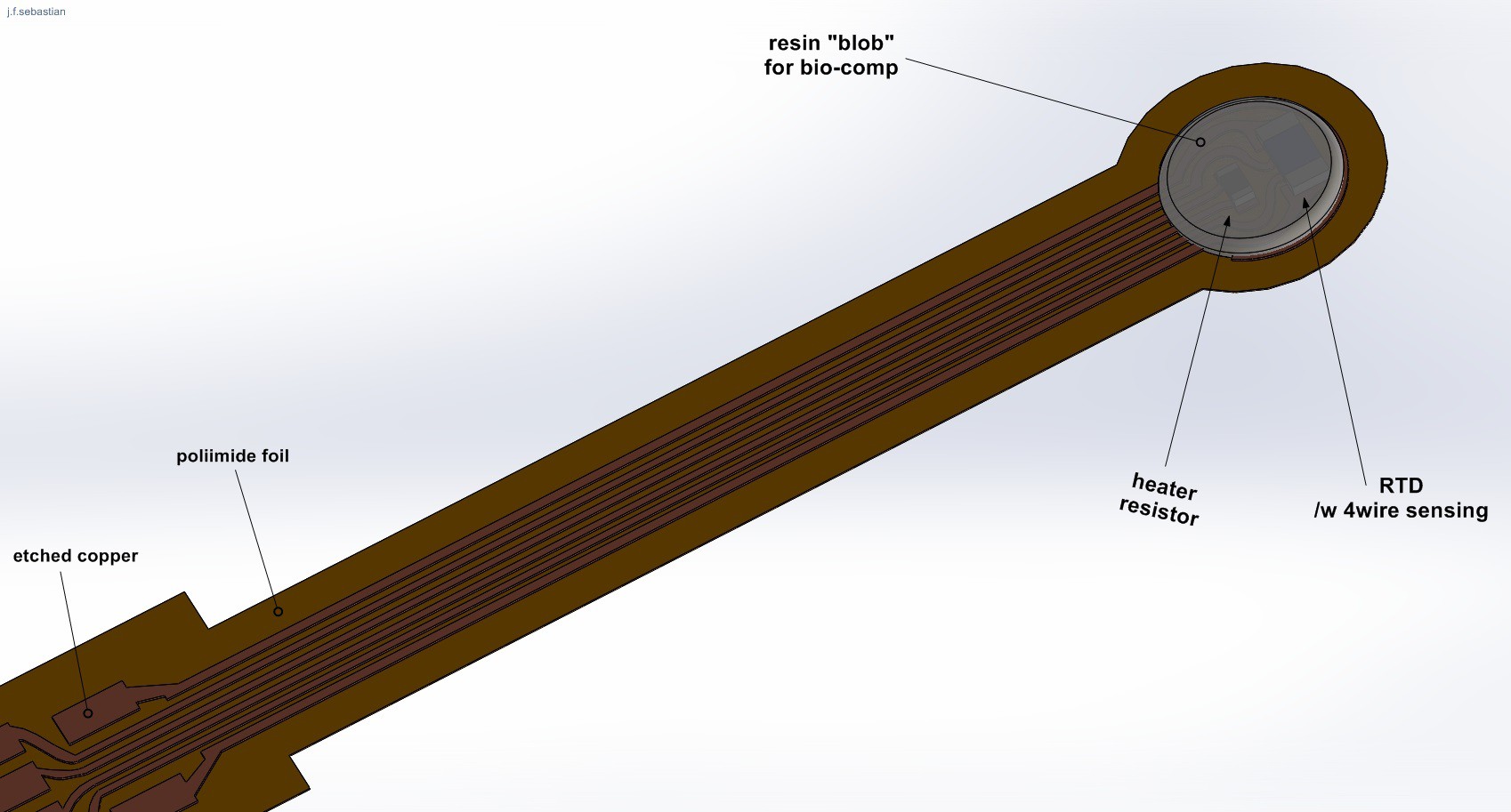

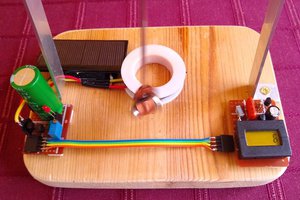

The idea is simple. Use the section between heat detect and pain threshold as communication interface. Let’s heat the small resistor, in controlled manner, to quickly dissipate, programed heat dose. Just enough for stimulate receptor. Let it be or 1 signal. Now, as our device is basically strapped to big, efficient, fluid-air cooled heat sink (aka human body) resistor will cool relatively quick - our 0 (no signal). Braille is all about to detect six signals (dots) at a time. So the proposition is to make flexible circuit, with six "dots" on hand strapped, thin foil connected to a bracelet. That is for output.

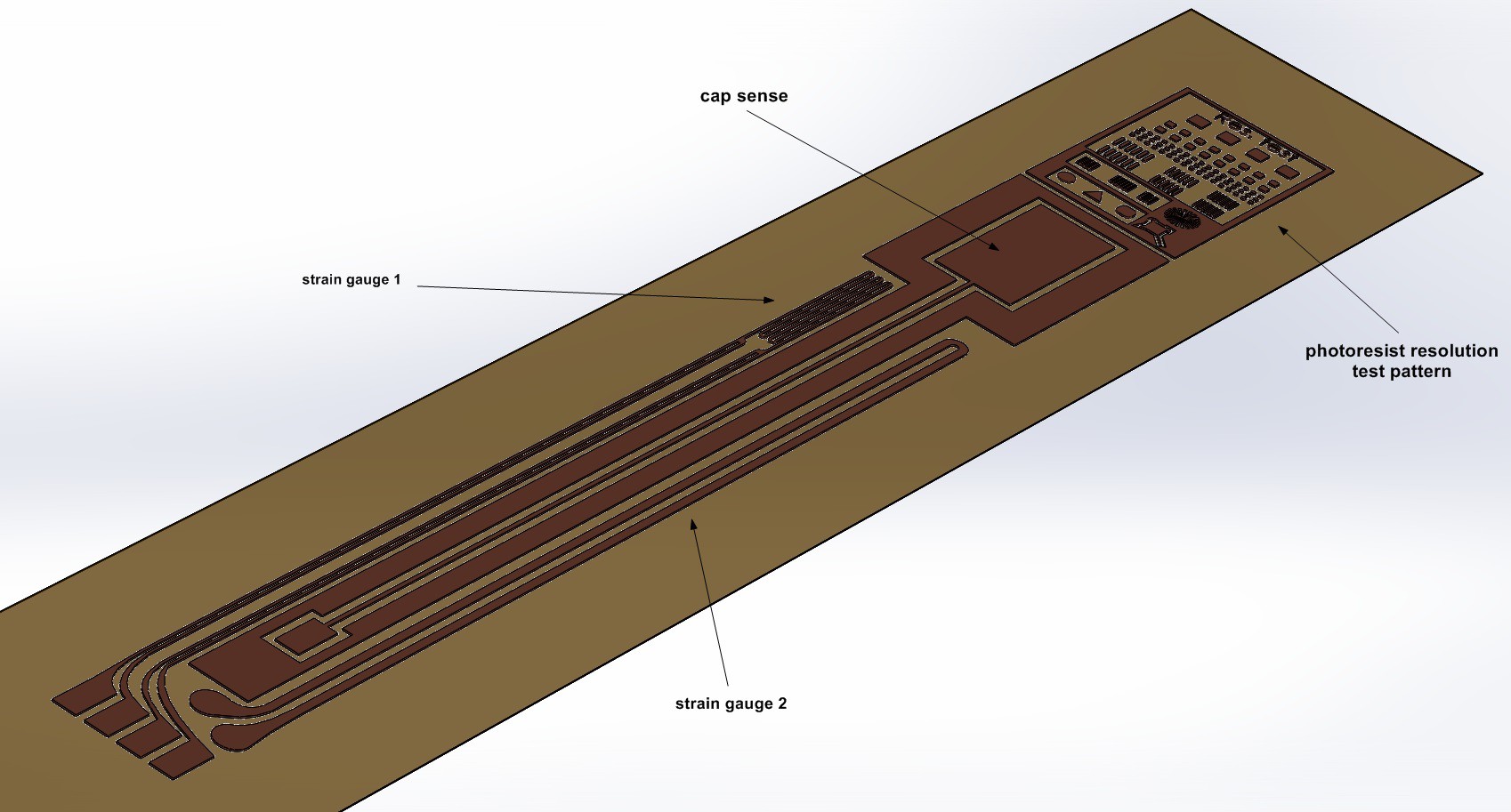

For input, moving fingers and thumb area will be pickup with strain gauge, just like on weight or universal testing machine for material samples. One big advantage of it is that it can be made thin and are precise. They can detect slightest movement, no need for full hand gesture. On top of that there is cap sense on finger tips for quick input when motion is not impaired.

The advantage of I see in that system is:

-small and thin - use of standard smd components and flex circuit, any shape, discreet, non-motion blocking

-cheap - from the above - use of existing, verified, mass produce technology

-outside application - video game feedback (shot), silent alert and communication

-easy indyvidual adaptation - both shape (silicone+polyimide sandwich) and thermal characteristic (res+rtd loop)

-if application turns out not viable, it will work as fancy hand warmer,

as winter is coming at starking rate.

To do and roadmap:

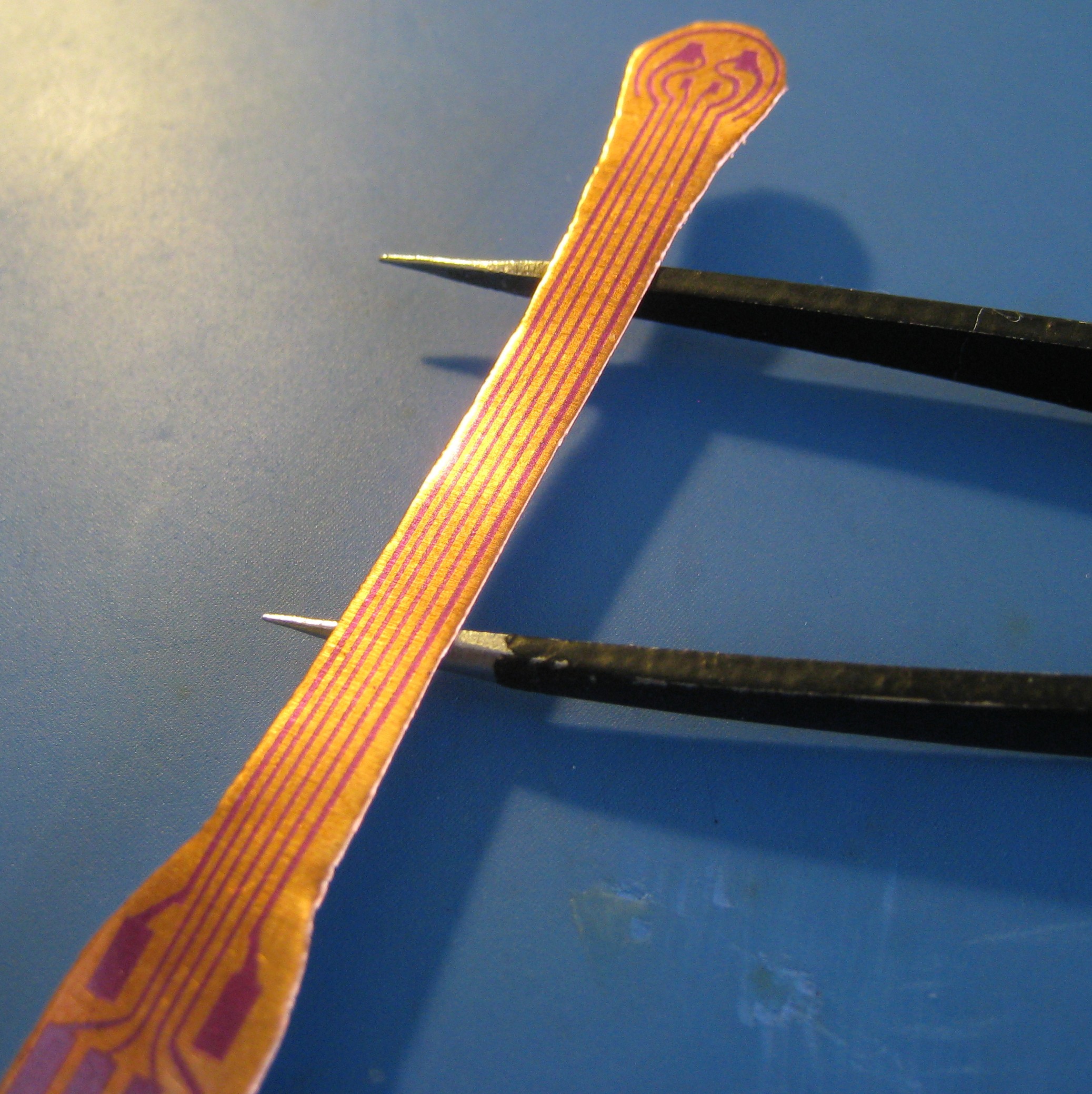

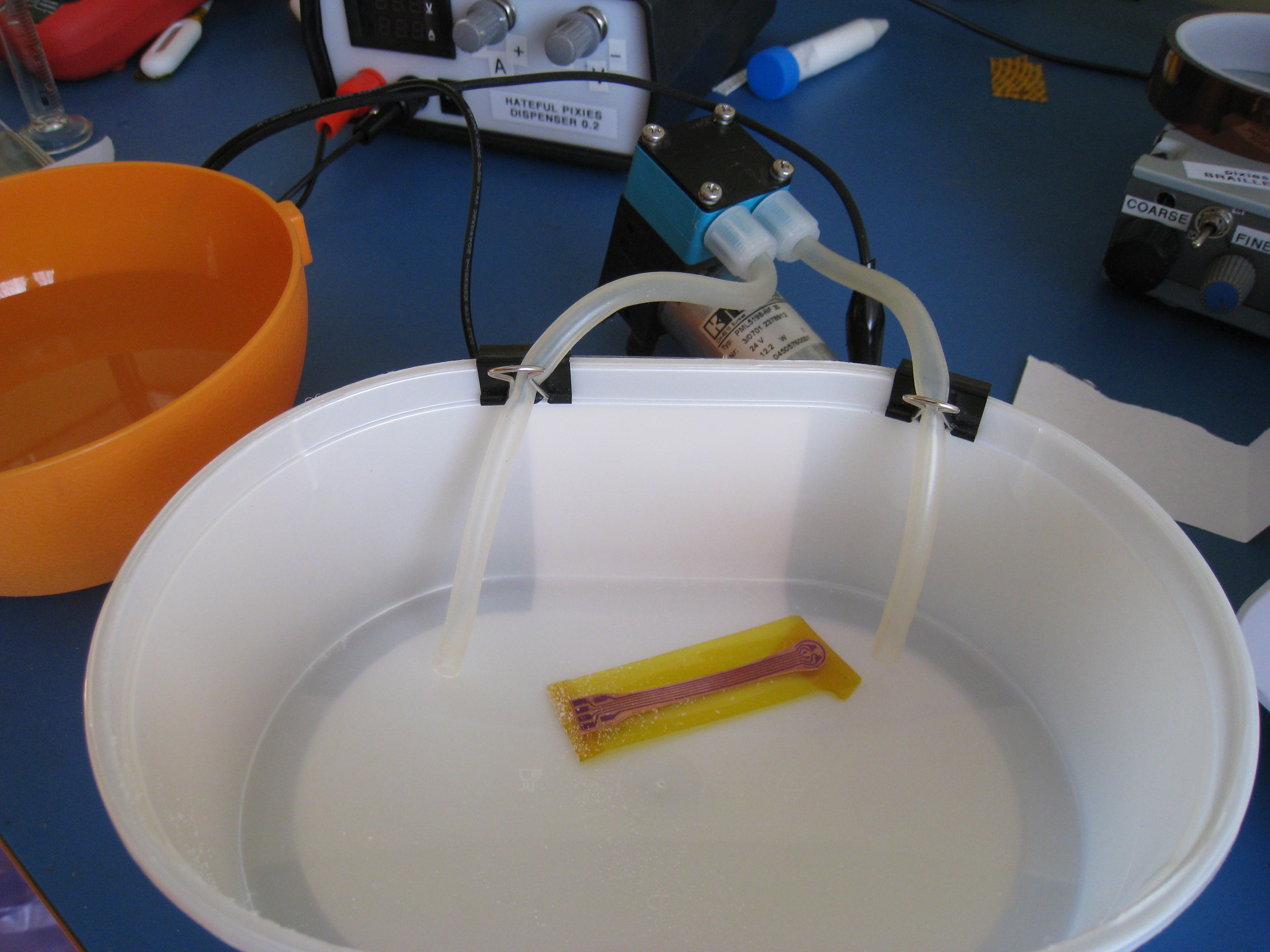

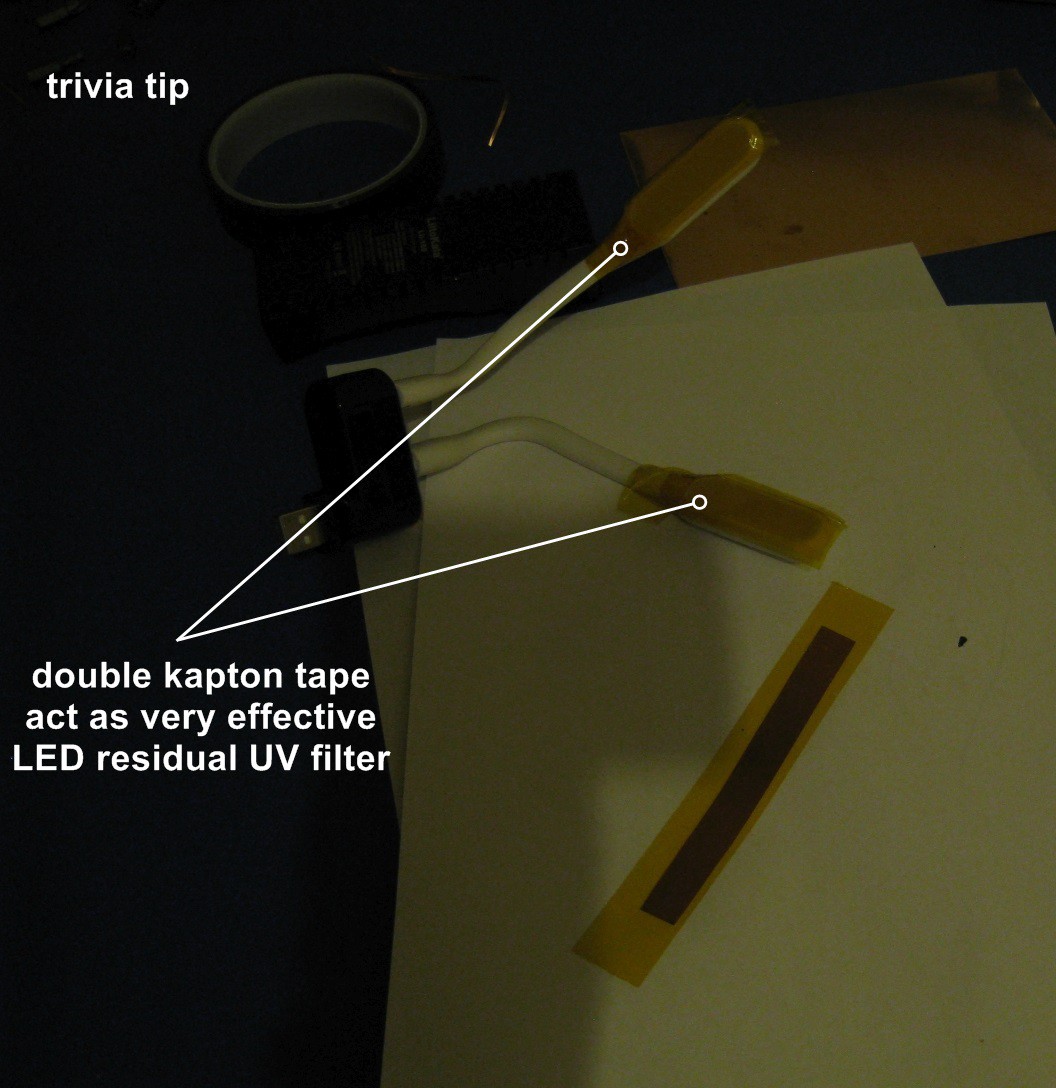

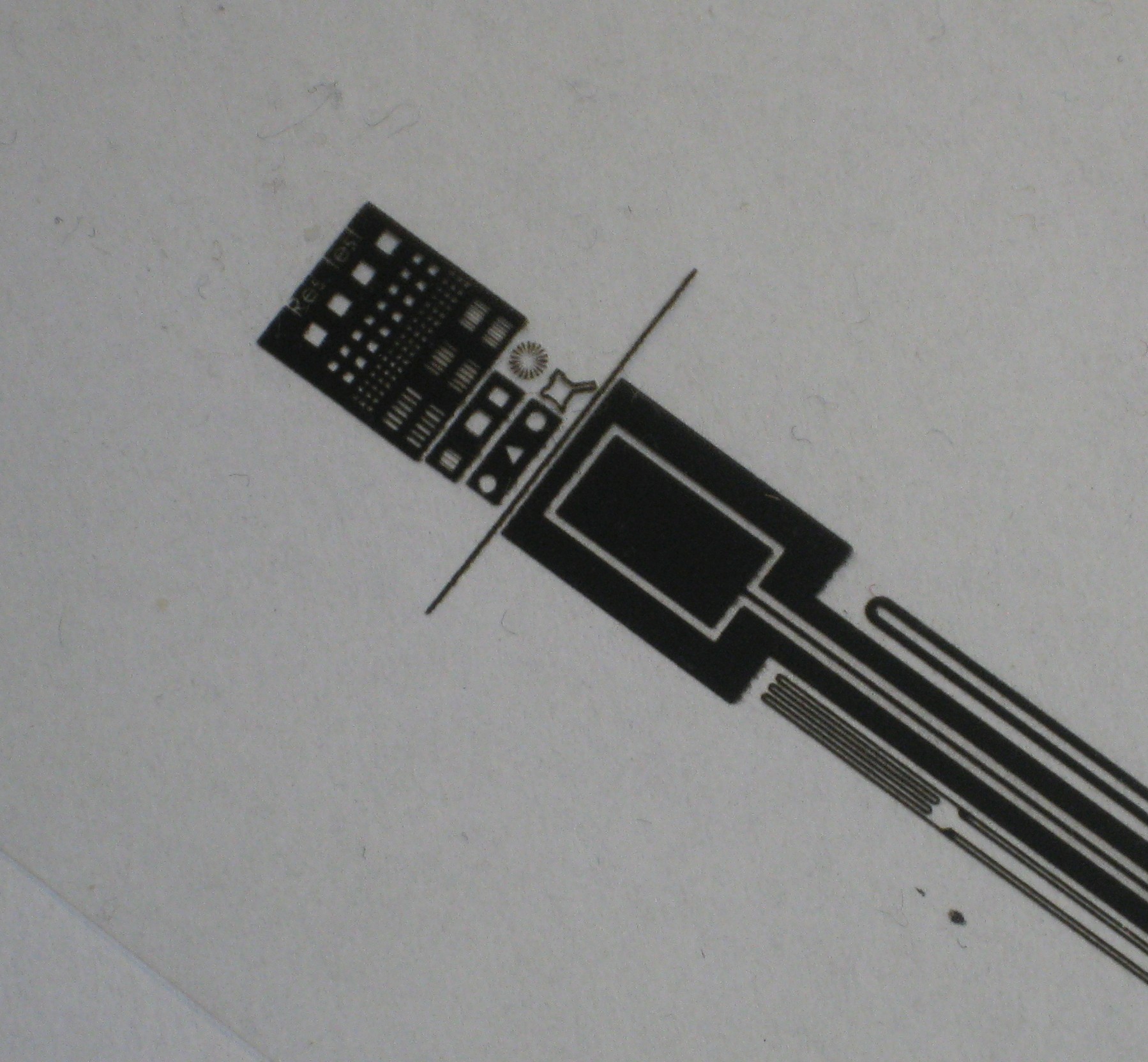

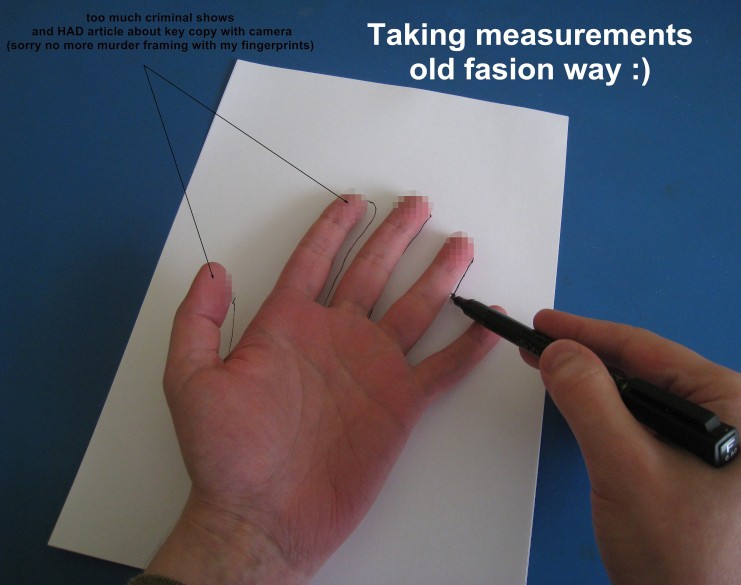

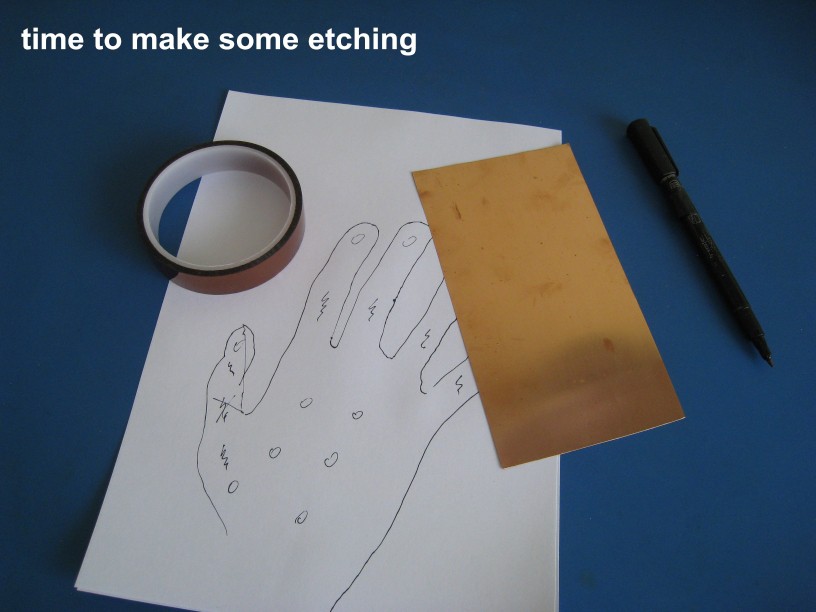

-test the idea - prototype circuit with kapton tape and resistor to asses thermo receptor density in hand for efficient "dots" location

-asses thermal hysteresis of receptor to calculate maximum information transfer rate, recover time, etc.

-based on above calculate power requirements and chose hardware for bracelet (mcu,adc,mosfets,wireless stage)

-smartphone/computer interface, app for peer-to-peer comm, city navigation.

j.f.sebastian

j.f.sebastian

Javier Betancor

Javier Betancor

George Albercook

George Albercook

Saabman

Saabman