Reading about how to print NinjaFlex successfully, and after a few attempts to print it with the standard printer setup, my first goal was to replace the current MultiMaterial (MM) extruder with something with better filament support. Filament support, as best I can tell, simply means that the filament is given less freedom to deviate from the desirable path. I used the BondTech extruders as a baseline for this, I designing a different extruder part utilizing the same BondTech drive gears.

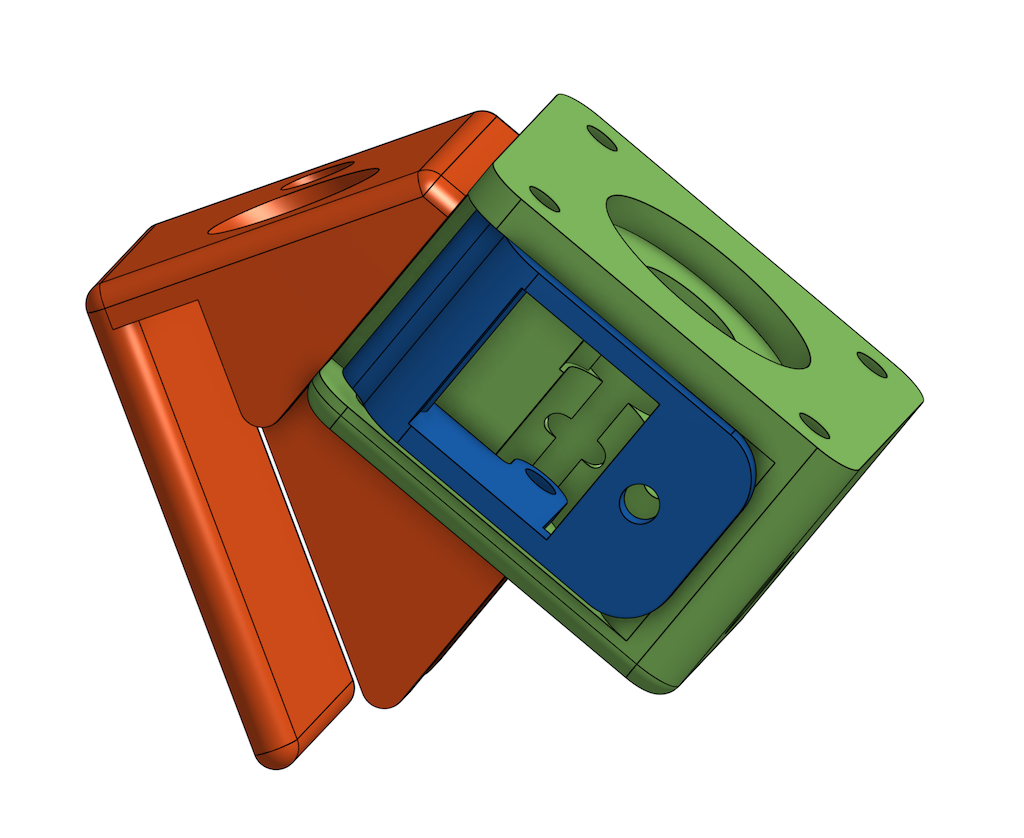

The extruder above is made from three pieces: The main body (green) onto which the stepper motor is attached, the idler (blue) to apply pressure to the drive gears and the clip (orange) to mount the extruder to the frame. I designed left and right handed version to match the rotation of the stepper motors on the Prusa.

In tests, the extruder performed very well, moving filament through the bowden tubes more effectively than the original design, especially softer filament. However, because the filament path is still very long, and not particular straight due to the MM multiplexer, this extruder still cannot push the NinjaFlex reliably into the hotend as it compresses too much. So, not the magic solution to printing NinjaFlex on the MM Prusa.

Tim Wilkinson

Tim Wilkinson

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.