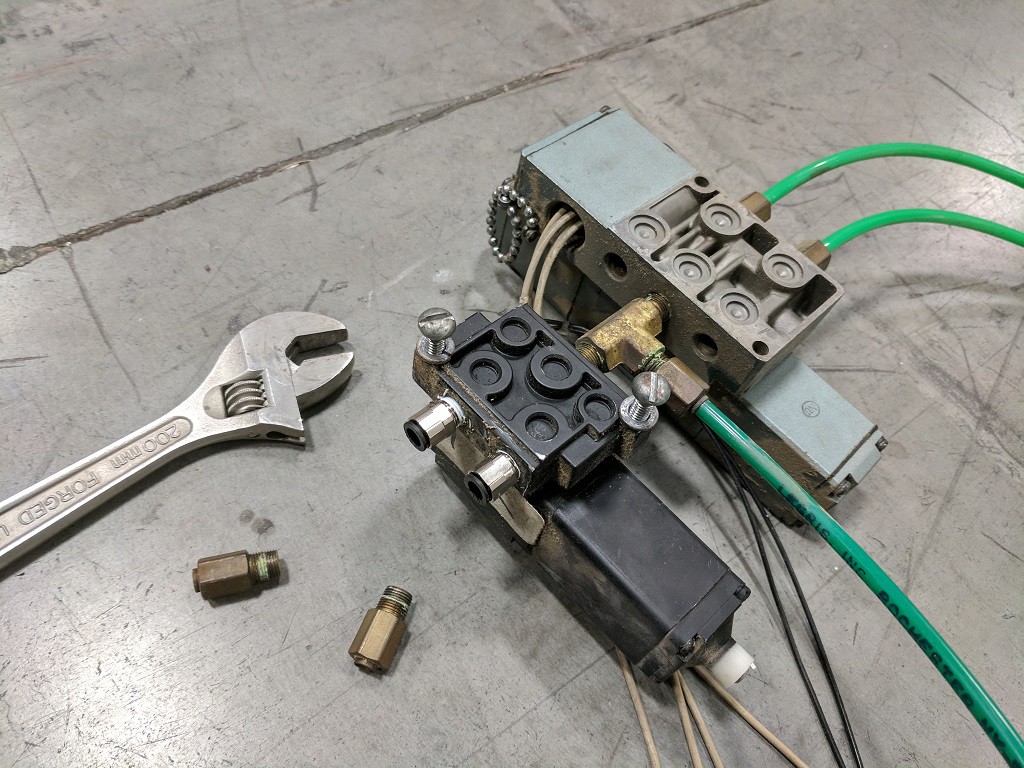

We've just completed the milestone of replacing the compressed air fittings and lines in the machine. We replaced the fittings because we expect the old air seals within them to have decayed with age. Since we have everything disassembled, replacing them now is relatively easy and reduces many potential points of failure.

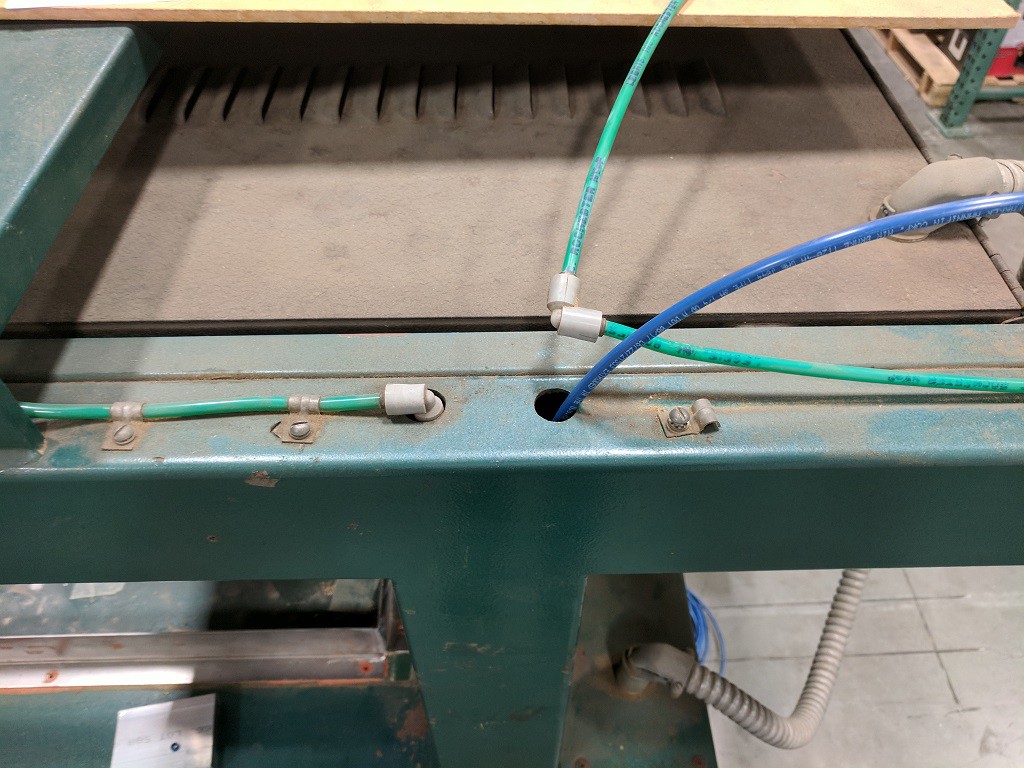

The same logic also applied to replacing lines carrying compressed air throughout the machine. For extra bonus, the new air lines are blue and the old ones are green, making it instantly visible which pieces have been replaced.

Once the compressed air subsystem was buttoned up, we wanted to do a subsystem test. Since we have yet to wire up the 220V power distribution, we can't run the built-in air compressor just yet. So we unplugged the output port of the air compressor and plugged that into the shop air.

Loud hissing announced the presence of a leak in the system. We felt all around the newly installed air lines and fittings, but the source of the leak wasn't any of the new stuff. We eventually located the source of the leak to the compressed air tank that we had not yet touched. Before this test, the quality of the air tank was a question mark. Now that we have finally pulled it out and gave it a good look, we have answer to that question!

During disassembly we noted there was no air dryer between the compressor and the tank, so moisture would have collected in this tank. There is a fluid drain port (not visible in this picture) but it doesn't look like it has ever been used. This hole implies the inside of the tank is a rusty mess and a hole patch repair would only be a futile short-term solution. If we want a self-contained machine not dependent on shop air we will need to replace this tank.

After this discovery, we disconnected the air line from the output port of this tank and hooked that up to shop air. It allowed us to test the rest of the machine.

- The mechanism to move the heater rearward seems OK.

- The mechanism to move the heater forward has a leak that needs to be investigated.

- Trying to move the heater forward/back repeatedly showed no problems (aside from the above leak.)

- The mechanism to move the frame up/down each seems OK individually.

- Trying to actuate up/down movement rapidly would cause the two sides of the air cylinder to fight each other. We are missing an air relief mechanism somewhere in the system. Either we forgot we removed something during disassembly, or an existing relief mechanism has plugged up.

Roger

Roger

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.