Since we just tested the air subsystem and found problems that will probably require buying parts from McMaster-Carr, we decided to perform a vacuum subsystem test with what we already have on hand to see if we need to add anything else to the shopping list. Only some of the fittings and vacuum lines have been replaced, and the vacuum table itself is in pieces, but we can put together enough to test the vacuum pump, the accumulator tank, the solenoid-actuated vacuum valve, and the fittings and lines connecting them.

We were happy to see the system could generate vacuum beyond an indicated 25 inches of mercury. This measurement is taken with a grain of salt coming from the old vacuum gauge that was on the machine. But while the absolute value ("25 inches") might be suspect, the relative value is still useful information. We shut off the vacuum pump and went to work on other things. After 15 minutes, the vacuum held steady enough that there was no visible movement of the needle.

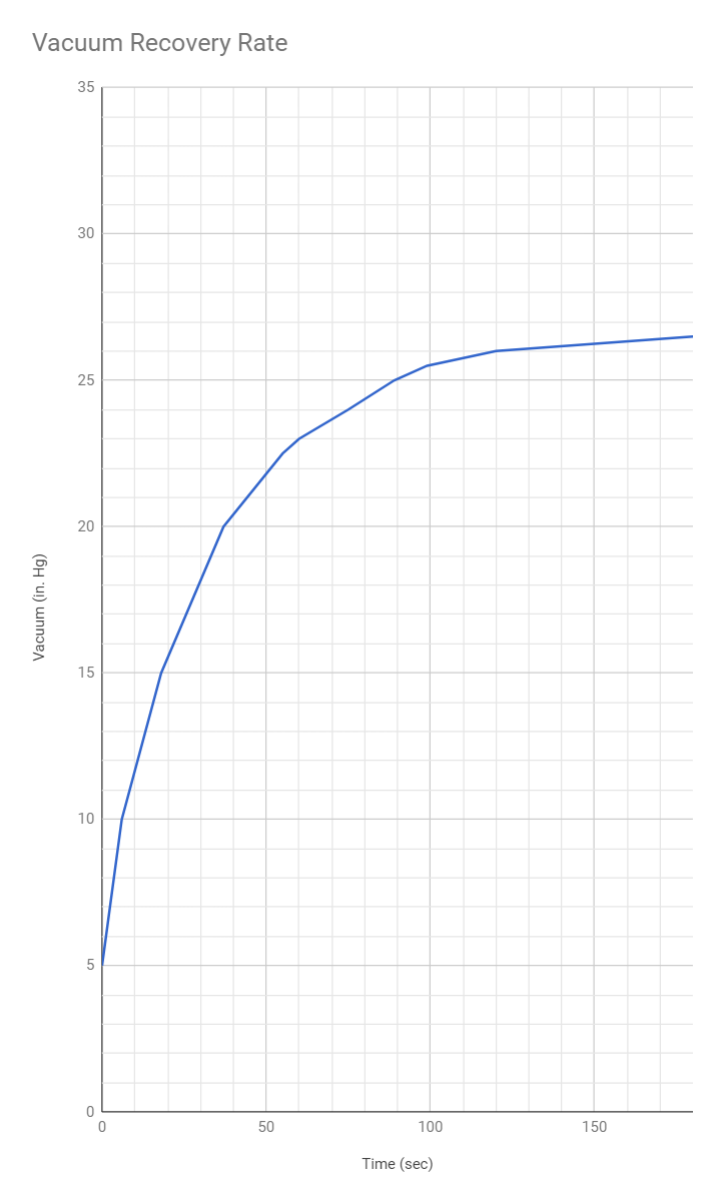

The next test is the rate at which vacuum is generated. We don't need it to be super fast, but we don't want it to be the limiting factor in cycle time. As soon as the softened workpiece is pulled against the mold, the vacuum should start building back up. It can continue doing so as the completed workpiece is removed and the next workpiece is loaded and heated. By the time the next piece is heated, we want to have sufficient vacuum in the system ready to go instead of having to wait.

Using the solenoid, we opened the valve and admit air into the system, dropping the vacuum down to an indicated 5" Hg. We closed the valve and started writing down the vacuum reading relative to a stopwatch.

The recovery rate is acceptable. After one minute it was back up to an indicated 23" and 90 seconds brings us to 25". It didn't have much grunt beyond that - it took double the time (an additional 90 seconds or 3 minutes total) to reach 26.5", where the needle stopped moving.

We expect a new pump to recover vacuum more quickly, and provide a stronger vacuum, than this tired old thing. But this performance indicates the vacuum pump will not be the limiting factor in our cycle time and that's good enough.

Roger

Roger

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.