During this summer, I made 31 loggers and deployed most of them in sea turtle nests, a few at random beach locations, and a couple in constant-temperature chambers at the local National Park HQ.

While I'm pretty happy with the loggers themselves, the "waterproof" casing was disappointing. Most deployments were in very moist or wet conditions, with salt present, so this is not entirely surprising.

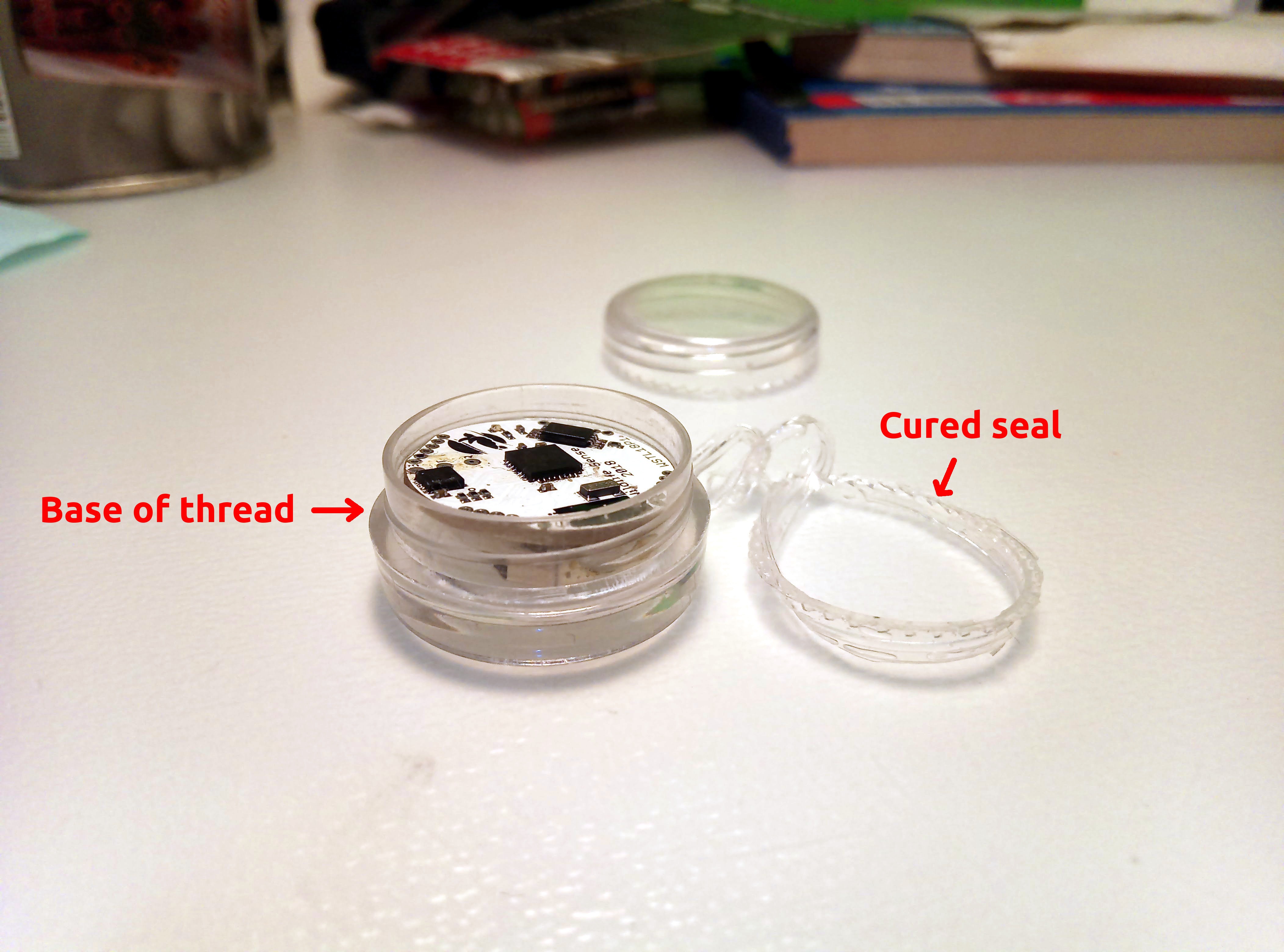

I used low-cost acrylic 3ml jars and planned to seal them with some sealant silicone.

Sealing method 1: Failed

I started with clear silicone placed around the thread on the base part.

Once the silicone cured, it was ready for deployment. The seal had to be broken at the end of logger deployment, but the case could be re-used.

I used this method on the first six loggers, which I tested for a few days at 32cm depth in one of the local beaches. Just a few days later, I went back and retrieved the loggers.

Five of the six loggers survived the initial test. The sixth one also worked but had stopped logging. All loggers showed some signs of corrosion but the limited time, just a few days, didn't allow the corrosion to progress.

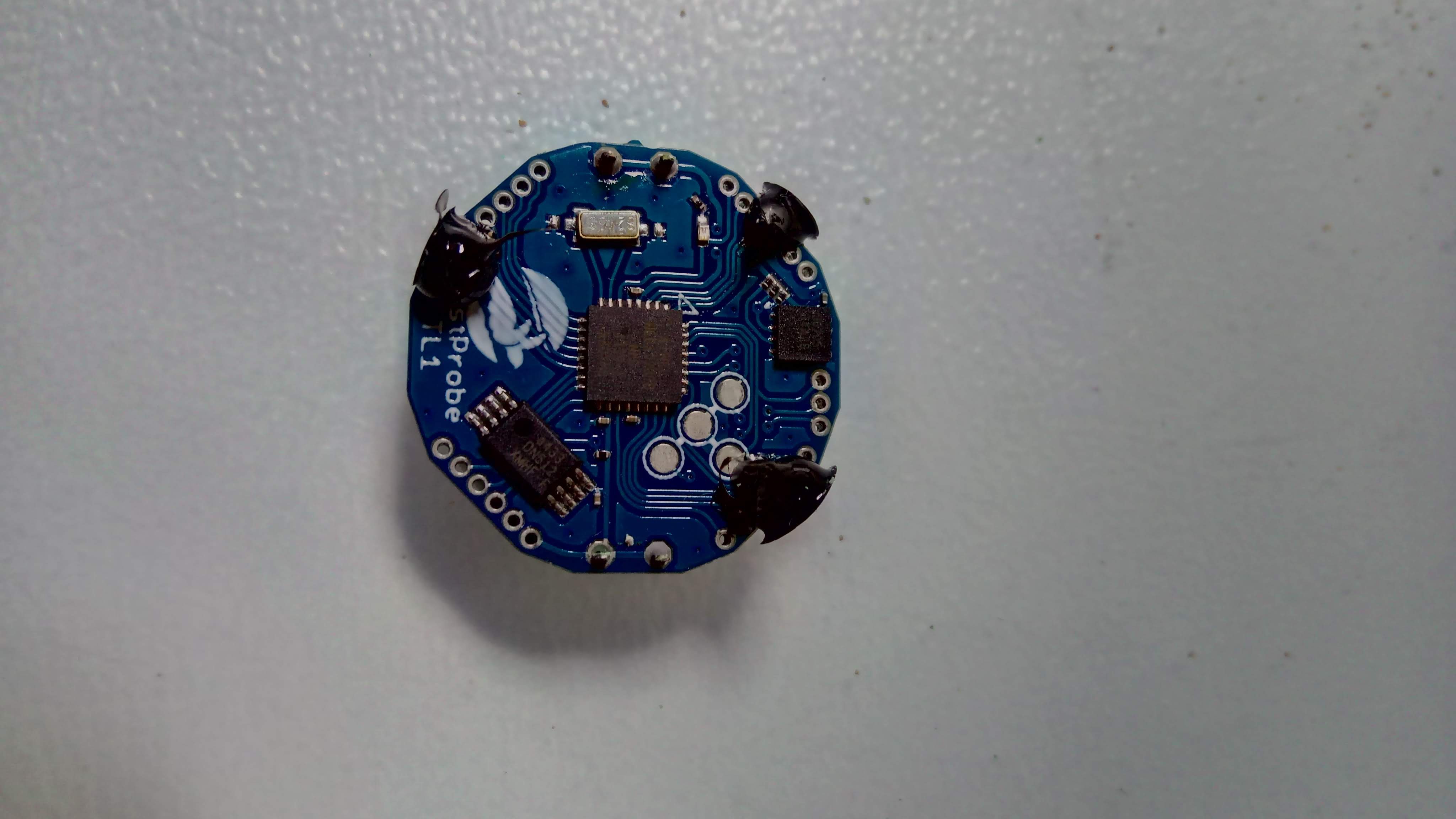

This photo is from one of the loggers above that was re-used and had accumulated more corrosion:

In this short-time deployment, the uart pogo-pin connector functioned without problems.

Sealing method 2: Failed

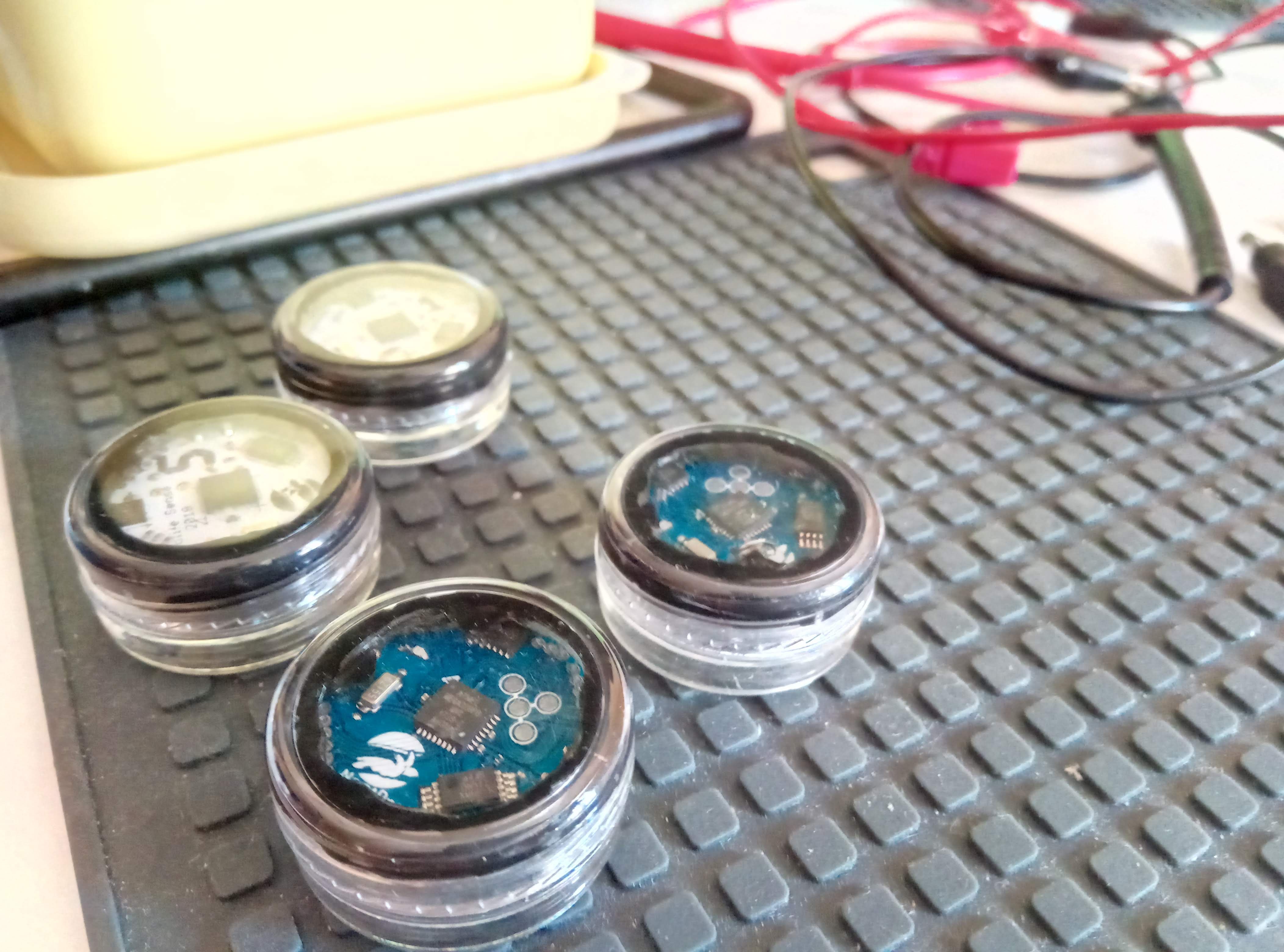

Using clear silicone to seal the jars meant that I couldn't see if the seal was complete or had any gaps. So I transitioned to black silicone and placed it at the top of the thread, between the base and the lid parts of the jar.

The thin sealant layer is hard to see in this photo. Alcohol, contact cleaner, or nail polish remover didn't help at all, only persistent mechanical force helped just enough to download the data.

With this method, all loggers had some corrosion on the battery holder, which was at the lower part of the case, but worked until retrieval after several weeks in very wet sand. Still, the contact insulation problem meant I had to return to clear silicone.

Sealing method 3: Perhaps...

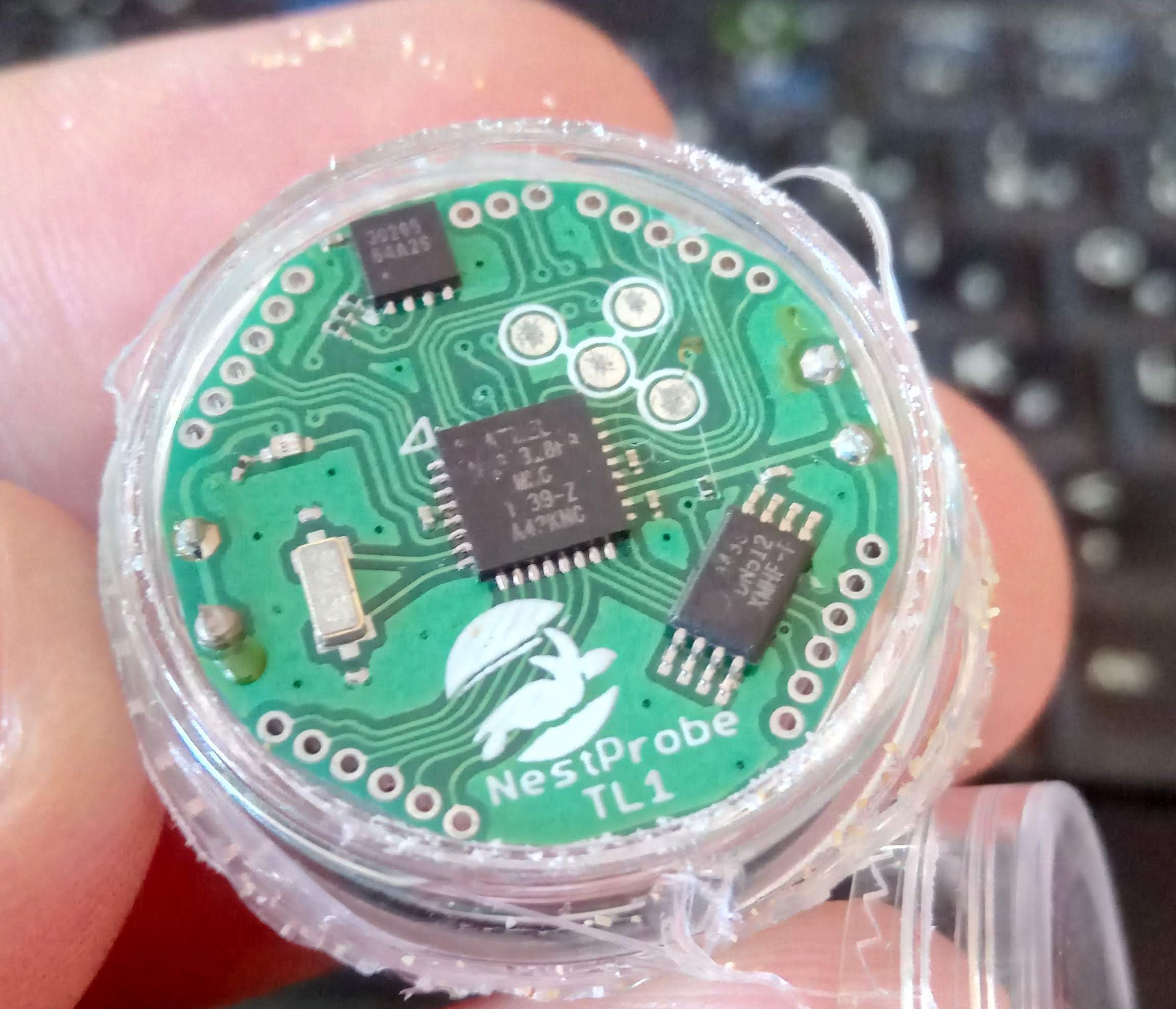

For the third method, I was able to find circular pads that are used to seal these specific cases. The seal is not meant to be water-tight, so still had to add silicone around the screw-cap thread.

This is how two loggers looked after retrieval. Number 23 had been used previously and was already corroded, so only number 27 was new.

I still had a small deposition on the contact pads.

This caused limited problems on control and data download. I could use it ok, but wouldn't release this to "regular" users.

It's not a sealed deal ...

I'm pretty sure there is a limited leak of salty moisture into the logger case. At this point I'm not prepared to move to a custom molded solution, so I'll stick with method 3 with some extra method to strengthen the seal. With the nesting season over, I have all winter to work on this.

Nikos

Nikos

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.