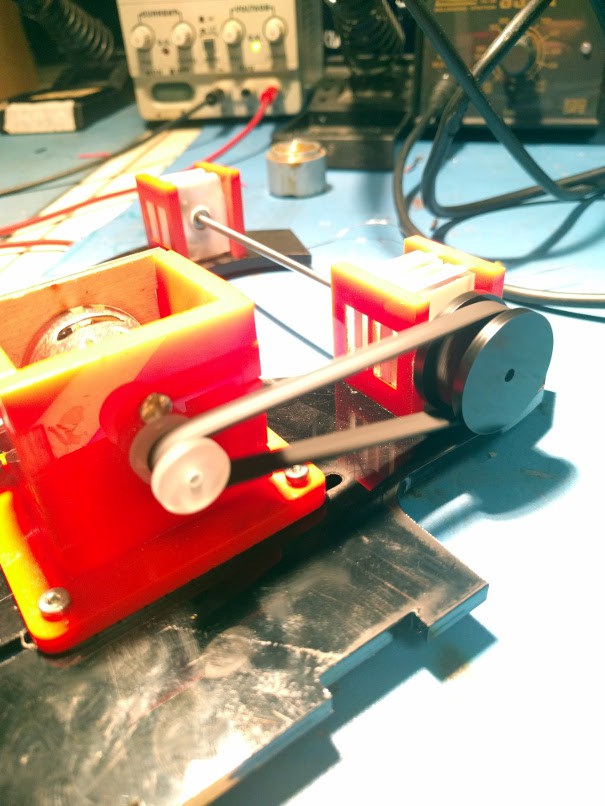

When we last left our intrepid hero - I mean the laser cutter, obviously - we were waiting on properly sized belts. I have received and installed one and spun up the machine. 200mm was a good size. It works, in this configuration!

The motor draws about 10.5W, and seems to go at a good clip. I should measure it at some point.

I still haven't found a silver bullet for my PCB coupling issues. The goal for today is to attempt one of the possible methods and see if it works. It wasn't written in the previous log, but I also picked up some nylon RC clevis pins. The bore is smaller than my 3mm shaft, however, and I couldn't find anything more appropriate.

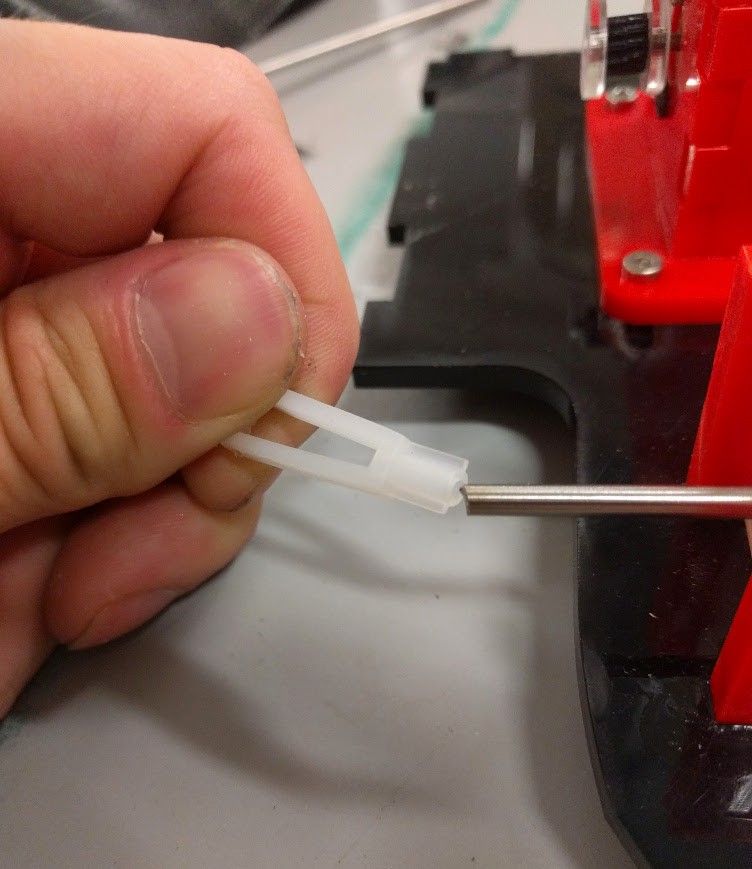

Instead of finding a 3mm drill bit and drilling it out, here's a neat trick that's much more versatile:

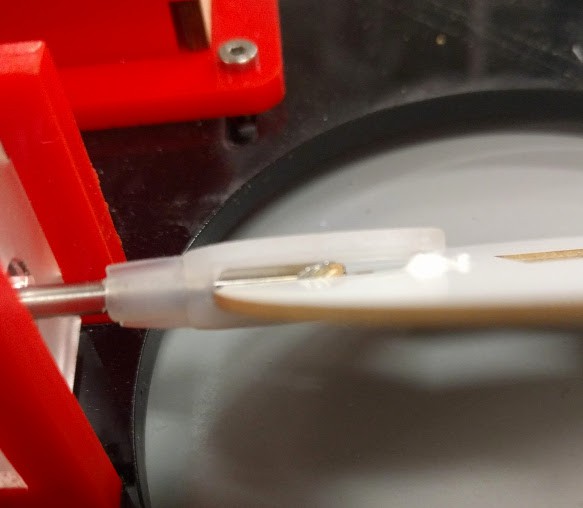

By grinding a flat onto hardened rod, you can turn it into very mediocre drill bit, with exactly the required diameter.

And then you can drill it into the nylon pins.

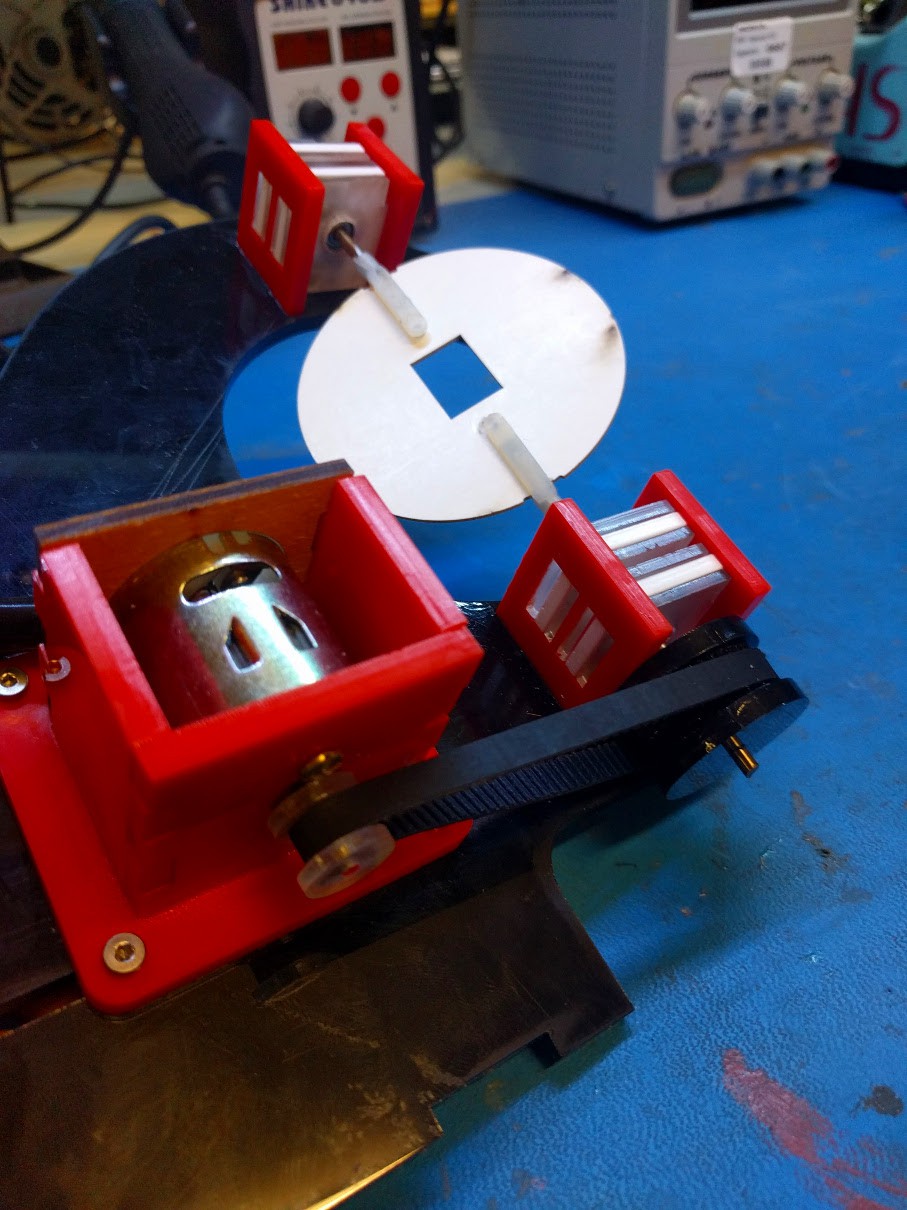

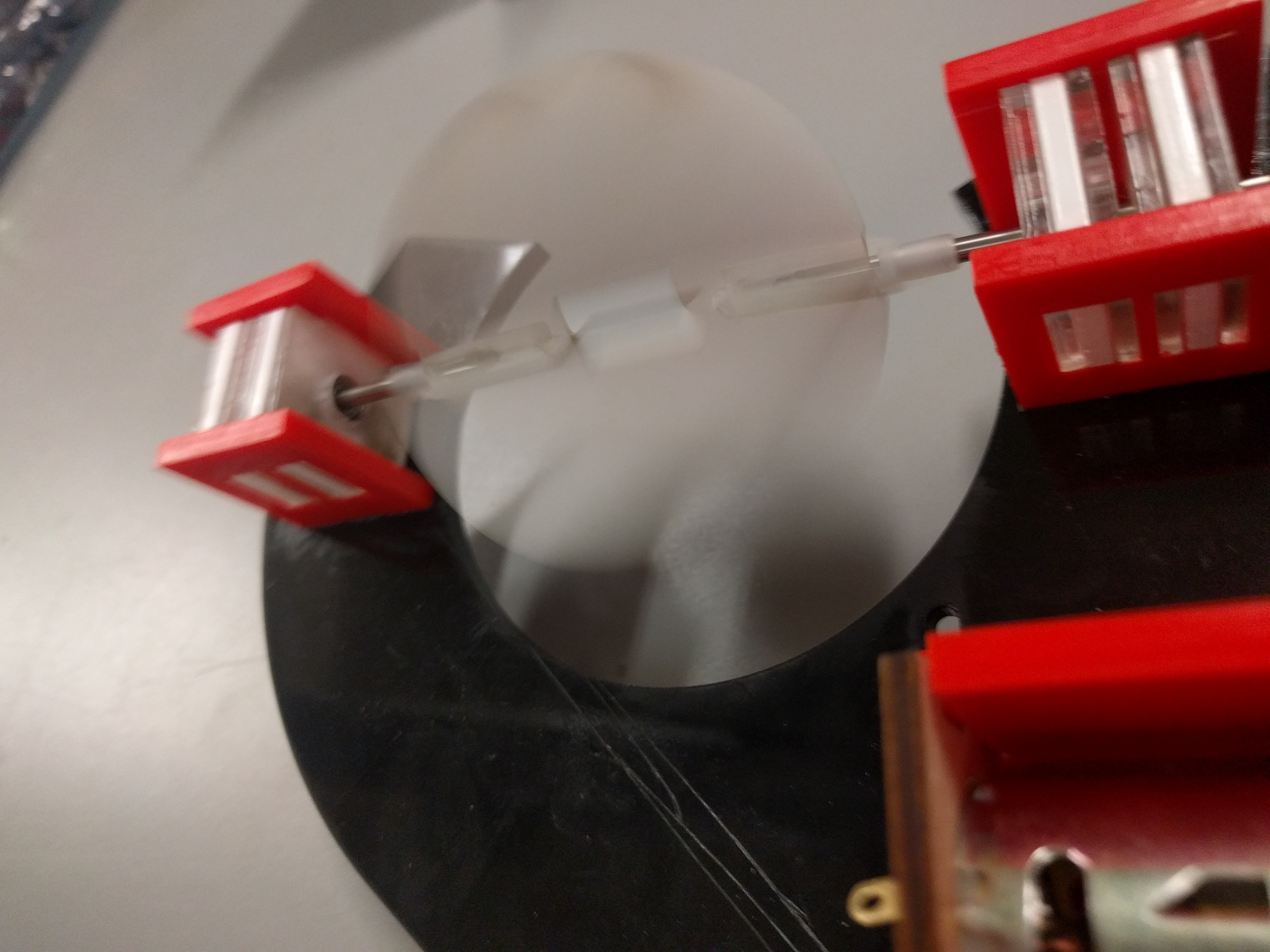

Here's the machine, completely assembled. That cardboard disc is a stand-in for my PCB, with a pretty similar thickness.

Spun up:

Yeah, I'm quite happy with the speed.

But it's now time to scrap this revision and rebuild it from scratch. Stay tuned!

Jarrett

Jarrett

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.