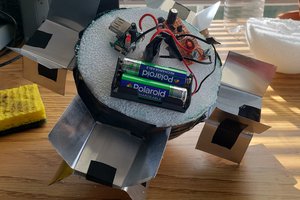

Based around powerful thermoelectric Peltier modules from Laird Technologies, the SuperVide has an operating temperature range of -10C to 100C. Peltier modules provide tremendous benefits compared to the normal heating elements used in typical sous vide designs, most notable of which is the ability to operate in reverse polarity.

Since the modules in question operate at 12V and behave similar to standard motors most of the complexity of driving heating elements is removed. There is no need for a complicated (and expensive!) PID module or solid state relay. In fact an ATX power supply in the 300W range supplies more than adequate amperage to run the entire machine, with the fringe benefit of supplying 5V for our microcontroller as well.

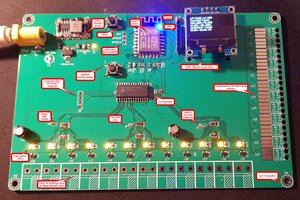

Completing the design is a standard 10qt stock pot available at your local supermarket, rigid foam insulation and some simple hardware. A 12V pump provides circulation and flow through the waterblock to which the Peltier modules are connected. Temperature sensing and control are handled by an Arduino.

No advanced tools such as a 3D printer or laser cutter are needed. Simple hand tools can be used for every aspect of construction, although a drill press does simplify some steps. The design is highly scalable and can be made in both smaller and larger sizes.

You can also adjust your temperature gradients, set predefined cooking or cooling profiles, and monitor status via a laptop or cellphone or anything else with an internet interface!

Carl Frega

Carl Frega

Red Tuka

Red Tuka

Chris Jones

Chris Jones

Kedric

Kedric