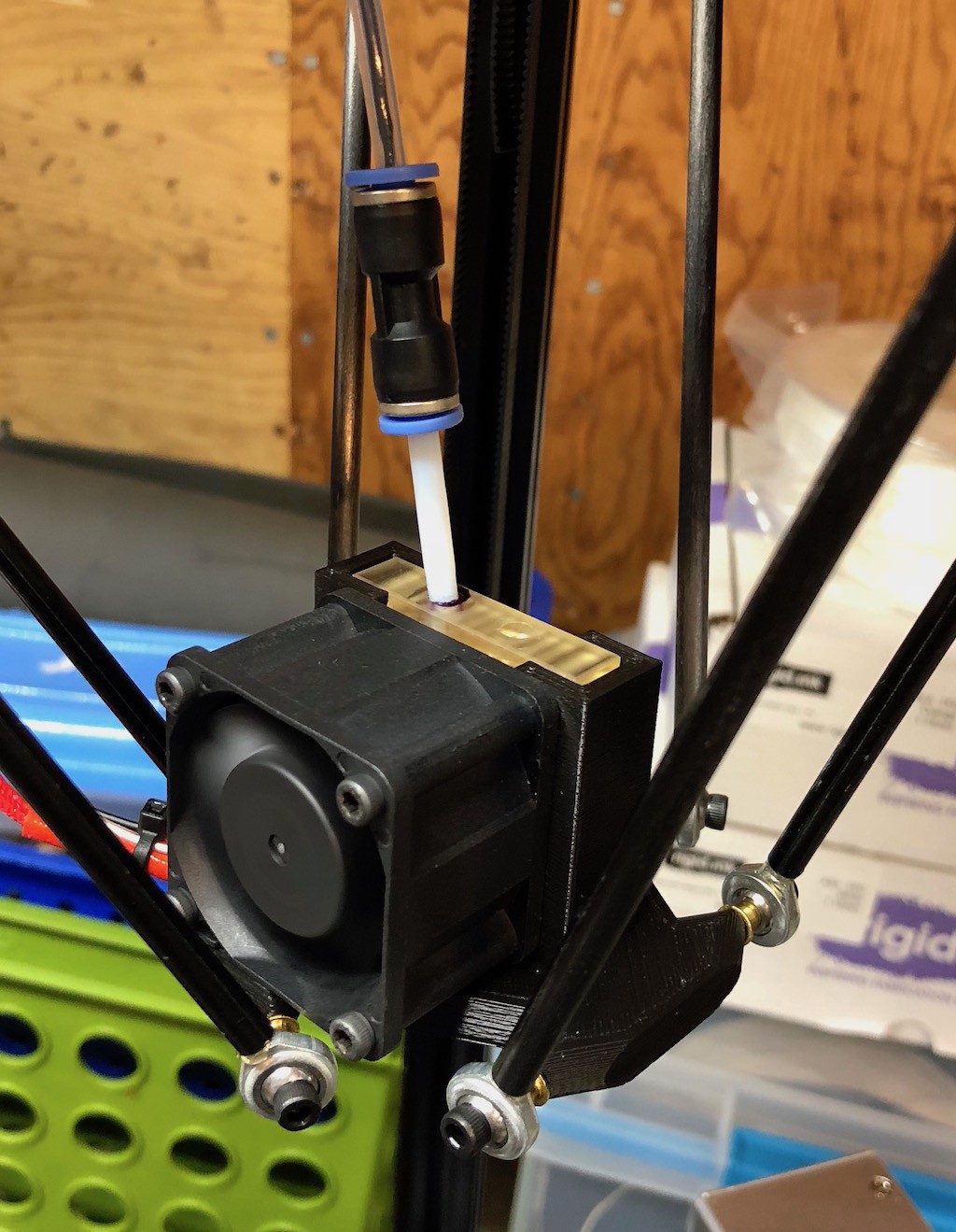

The hotend was assembled just as in the bench tests, with the heated block screwed into the base of the printed multiplexer. The multiplexer was then bolted into the Anycubic tests frame together with the cooling fan.

The final piece was to glue a small piece of teflon tube into the multiplexer. Gluing teflon is tricky; the very nature of the stuff is that it doesn't stick. To make it happen I first treated the outside surface of the PTFE tubing using Loctite 770 which is a teflon primer. This allows the treated surface to bind to superglue. So, once the surface was treated and the primer had dried, I coated the tube with a little superglue and then stuck it into the multiplexer. I came back an hour later (not entirely sure how long it takes to dry) and the tube was nicely bonded.

Finally, I ran a simple extrusion test using the current extruder to push filament into my new heated hotend. I was rewarded by hot filament dribbling out of the nozzle.

Tim Wilkinson

Tim Wilkinson

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.