that name... just now imagined, might just do the trick... (was trying to figure out what to demo with this thing)

Herein, I plan to document plausibly the most ridiculous of my endeavors, to date...

Wherein there are planned two subprojects to demonstrate a technique I've come up with for increasing the amount of data that can be stored on media such as floppy disks, and maybe extendable to similar media still in use today, such as hard-disks.

(It's plausible this technique already exists, but I have not read of it previously).

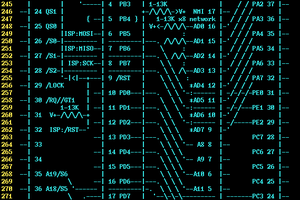

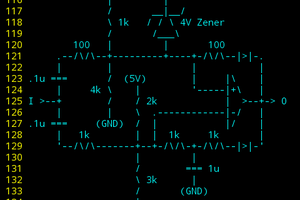

The first subproject will use this technique to store and play-back audio directly on a diskette using an unmodified drive and a handful of discrete components (comparators, mostly). No microcontroller is necessary for concept-demonstration, though may be added later for increased functionality.

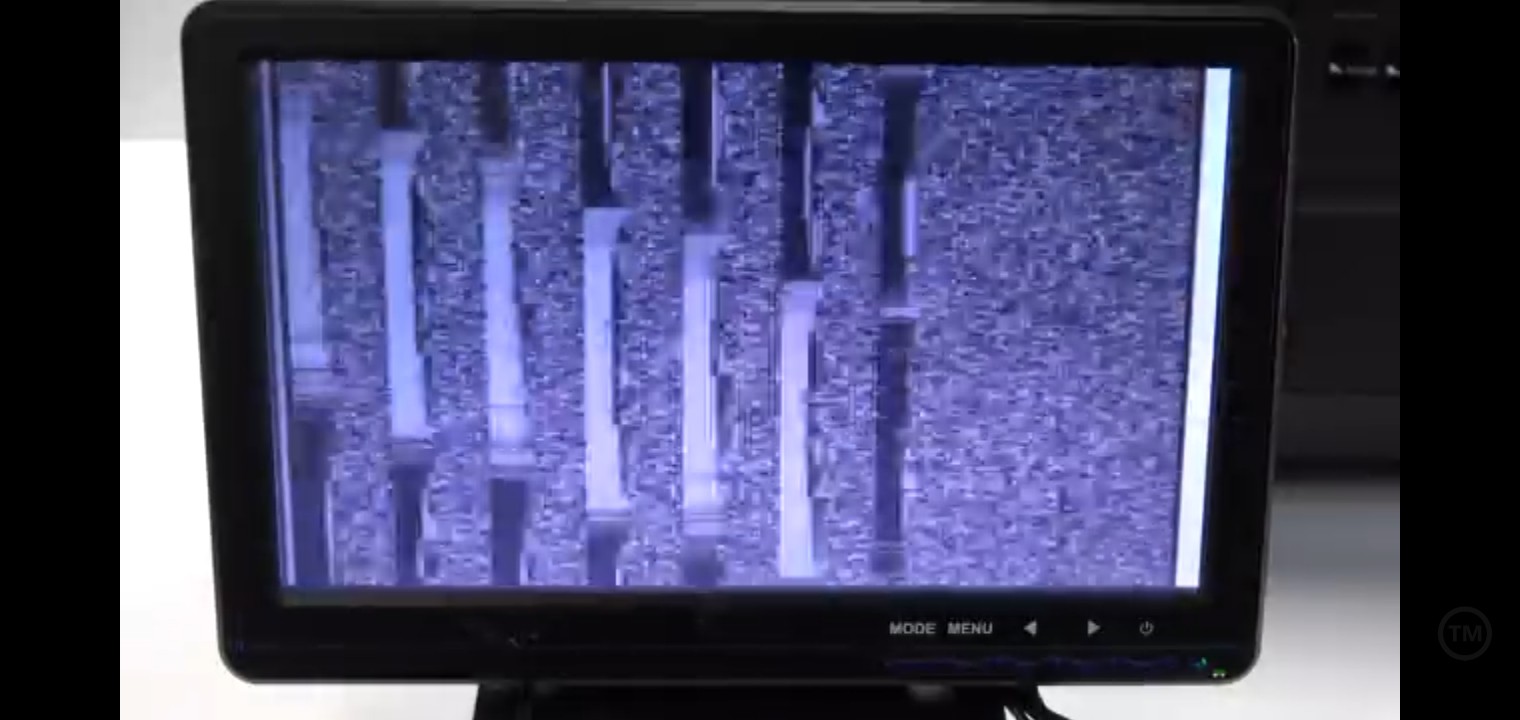

The second subproject, and likely my most-ridiculous, ever, will use this new storage technique to use a floppy diskette as a framebuffer for an LCD.

Briefly: each track will contain an entire frame, refreshing the LCD once with each revolution, at 5Hz.

(160 images! Think: HyperCard, or maybe a digital picture frame).

...

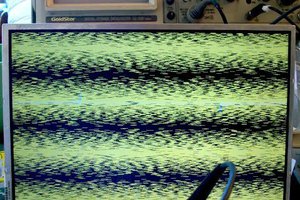

A standard 3.5in 1.44MB diskette is recorded at 500kb/s, and spins at 300RPM, or 5 rotations per second, 100,000 bits per rotation... left spinning on a single track, those 100,000 bits repeat...

A 240x160 LCD has 115,200 pixels... it's like a sign or something.

(Actually, it has 38,400 three-color pixels)

A) the 500kbps data rate is a guarantee by design, and can likely be bumped up a bit, especially on outer tracks... so a 15.2% increase should be doable. That doesn't include invisible pixel-clocks, used by the "porches", but... worst-case we lose some pixels at the right or bottom... definitely feasible.

But That's Irrelevent because:

B) a different, and possibly new, technique of magnetic data-storage is proposed:

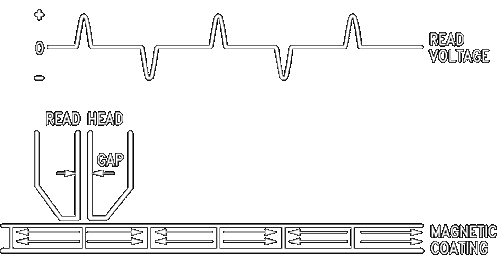

North... _____________

South... / \_\_\_\_______/

|--2us--|-1us-|--2us--|

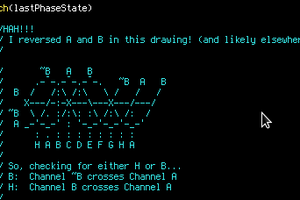

Floppies store data as magnetic flux transitions. The 500kbps limitation is due, largely, as I understand, to the minimum distance at which two "magnets" can be placed on the innermost track without repelling or attracting each other too dramatically as to affect the stored data.

The typical approach is to store these flux transitions at one of two locations, depending on whether the bit is a one or zero. Thus, data is stored such that each data bit occupies essentially the minimum amount of space which can accomodate *either* flux-transition mapping without affecting the next bit.

What I'm trying to say is that every bit contains (or at least is big enough to contain) a flux transition in either of two locations, one of which always goes unused...

But it needn't be that way...

Imagine a digital oscilloscope... Say it samples at 100MS/s. Analog-to-digital converters that fast are typically quite expensive. So a trick often used is to have, say, two 50MS/s ADCs which are offset by 1/2 of their sample-period. Bam... 100MS/s.

Now look at it the other way... the ADCs aren't restricted to 50MS/s... they could just as easily be bumped down to 49.9999MS/s. It's not a factor of sample-rates divisible by 50, it's a matter of the resolution of the sample-clock. And the limitation of 50MS/s is merely a matter of the maximum number of samples that can be crammed into a second, put more clearly, a matter of how fast a single sample can be processed.

But those samples don't have to be evenly spaced throughout a second! One could just as well sample one sample at 1/50millionth of a second, and sample the next at 1/49.999 sec, thereafter (being nowhere near some multiple of 1/50mil).

Oy... bad explanation. Let's think about synchronous logic... say...

Read more » Eric Hertz

Eric Hertz

I just replaced the DVD-RW in my PC with one given to me by another "dumpster harvester". The replacement drive is almost new; it probably saw little use in an office as people seldom read anything on their DVD drives these days.

I'm the only person I know who actually wears out DVD-RW drives, doing an automated backup every Sunday, and the odd archiving of accumulated photos (in addition to archiving on (duplicated) portable hard disks and the cloud). I may not ask for a DVD-RW for my next PC workhorse build, or at most buy a portable drive.

At some point, probably when my stash of CD-RW and DVD-RW discs run out, I'll have to abandon the medium, like I did to floppies a couple of decades ago. Then I copied every floppy I had onto a couple of CD-Rs and consigned the floppies and drives to recycling heaven. It is nice to give a friend an encrypted DVD with my files just in case my house burns down, but I guess cloud backup can cover that eventuality.