My initial estimate of 33% efficiency was due to a bad supercapacitor from the junk box. I still haven't fully diagnosed the problem with that capacitor (high ESR might be part of the issue), but measurements with a new, verified, one look much better.

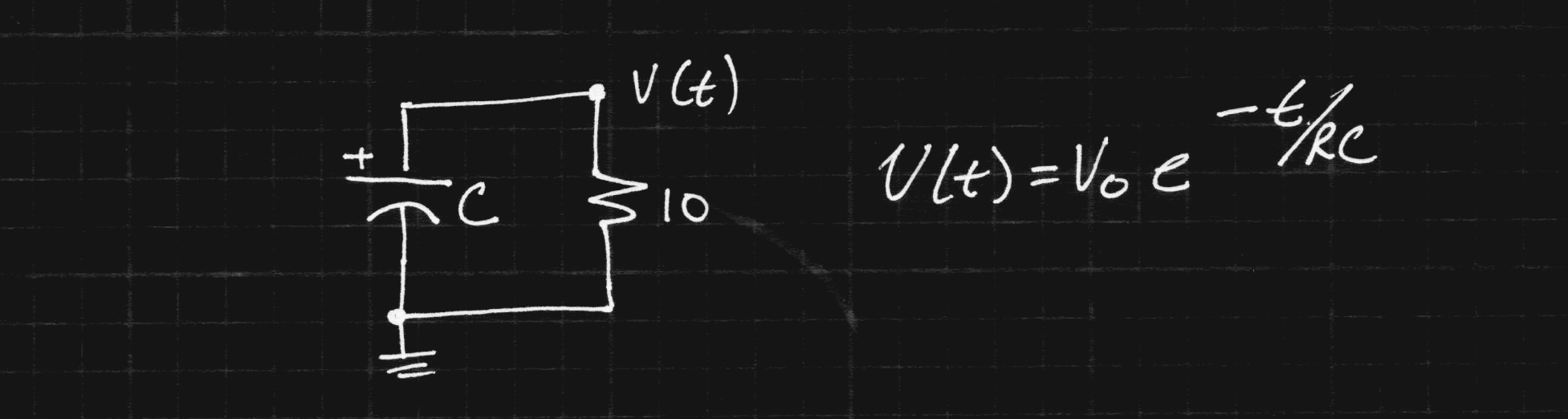

The 400F capacitors won't arrive until Monday, so I did some new measurements with a 10F/2.5V aerogel capacitor that I bought some years ago (it is now obsolete). Despite its age, it was still in the sealed DigiKey bag in my parts bin. To check its capacitance, I charged it to 2.0V, then timed how long it took to discharge to 1.0V when loaded with a 10 ohm resistor: 73 seconds. The voltage follows an exponential curve:

Using this equation, you can solve for C. It's a fun little exercise; I did it in 8 lines on a scrap of paper, but this maxima code will do the same thing faster:

solve(V[t] = V[0] * exp(-t/(R*C)), C);

Either way, you get the following:

Using this formula, we calculate a capacitance of 10.5F. Not bad for a -20/+80 tolerance part.

New Efficiency Estimate

So, armed with a validated capacitor, I timed how long it took to charge this new capacitor to 1V from a CR2477 cell with the converter. The converter was drawing around 34mA for 82 seconds. I will assume the battery voltage was 3V, because I didn't measure it (more about this below). This equals 8.4J out of the battery. Charged to 1V, the capacitor holds 5.25J, so the transfer was 62.5% efficient. This is much closer to what I would have expected.

So, there's a subtlety involved here, because under load the battery voltage is less than 3.0V. I've chosen to use the nominal 3.0V in the efficiency calculation because this will approximately account for losses due to internal resistance in the cell: the energy actually delivered by the cell is somewhat less, but this should give a rough approximation of the capacity of the battery that has been consumed. The 62.5% number is closer to an end-to-end efficiency measurement rather than just the converter itself.

So far, I haven't connected enough DMMs to monitor the cell voltage and current at the same time. I have three serial-port-enabled DMMs that I'll connect up once I clear some space on the workbench so I can log data during the entire charging process (cell voltage, cell current, and capacitor voltage).

Next Steps

So, the efficiency at low output voltages looks reasonable now. I'd still like to improve it, and will be looking more closely at where the losses are. But, losses are likely to increase when stepping up to higher voltages (like the 14V required on the big caps). So, until the final caps arrive, I'll find the largest capacitance I can that's rated for 16V or more, and time some higher-voltage charges.

Although the caps are still in transit, my 650A current probe did arrive (thanks, Amazon), so I can check out the voltage/current curves when starting my car (with the normal battery - for now).

Ted Yapo

Ted Yapo

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.