Things I learned from the first mold:

A) single sided mold and vacuum won't work

B) getting the parts out of the mold will perhaps break somthing

So I came up with the next mold. 2 parted, closed and with an extra layer of mold silicone to make possibly undercuts less problematic.

First, of course I needed a original part which was shaped correctly on the outer AND inner side. I did this by appling resin and cottonflocks in the missing corners of a bad part. just smeared some of it in the corners of the mold and pressed the part in, removing all resin that squezed out in the process. After curing I used a dremel and dentist millers to get the correct shape:

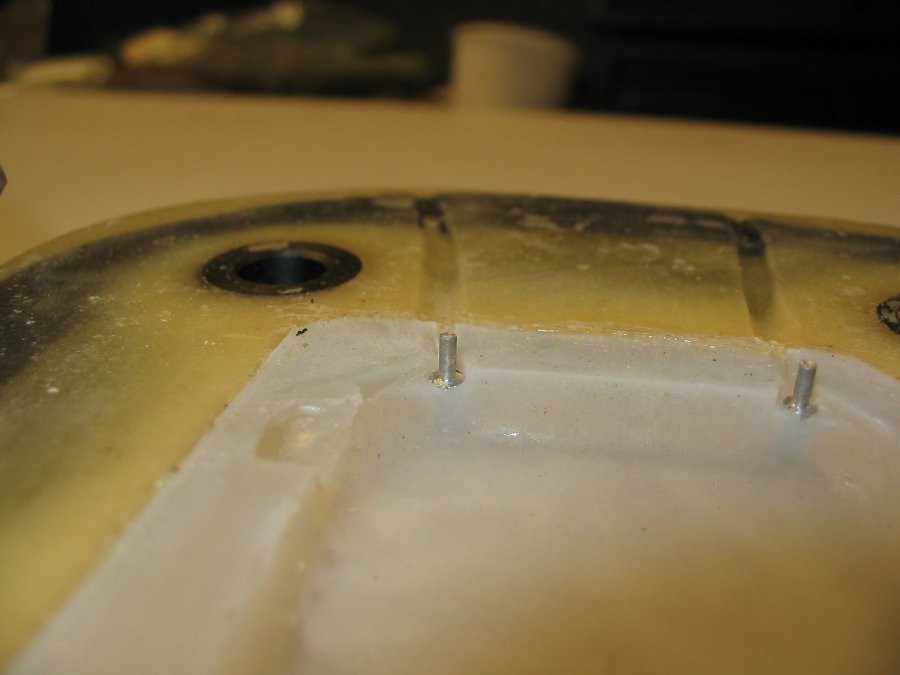

From that I got my new mold. For the mounting holes I used turned parts to represent the mounting holes:

(for the parts a carbon fiber ist wrapped aroud these parts):

While the trick with the carbon fiber worked fine, and releasing the parts from the mold worked as expected, there is a major backdraw:

closing the mold gives quite some tension onto the carbon fiber and for silicone isn't the stiffes material known, it was clear to my why this happens (not before I did it of course).

mclien

mclien

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.