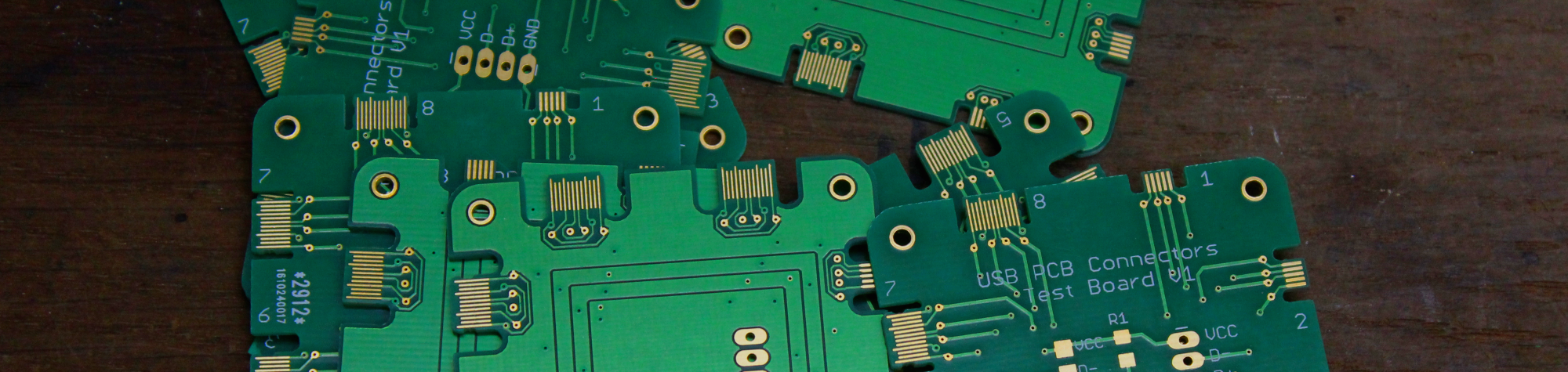

Before prototyping I wanted to test the PCB connectors first, because I have some footprint variants and I didn't know which one was the best.

For that reason I made a test PCB with 8 footprint variants, 3 for the micro b connector and 5 for the type c connector.

I ordered it from a very cheap PCB manufacturer, I had some problems with their web, and I had to do the order it 2 times. Because i was in a hurry the second time, I used the wrong PCB thickness of the board and ordered 1.2 mm PCBs.

I realized it when the PCBs come, two weeks later, so I was a little bit annoyed. The whole point of making the PCBs was to test the connectors, and with a PCB thickness of 1.2 mm I could not do anything.

(Luckily for me, this mistake save me from a possible laptop destruction, you will see why)

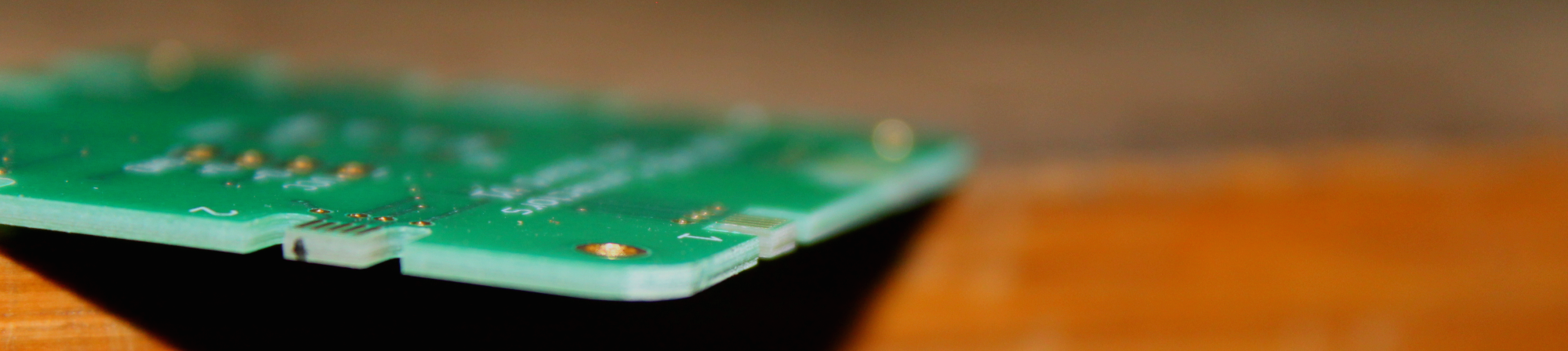

I don't want this PCB to waste so I tried to modify the PCB to make, at least, a rough test of the connector. Thankfully, those PCBs are made of FR4 material, and the way it is made is from thin layers of glass fiber, this make easy to scrap some layers to achieve the right thickness of 0.6mm (with the help of a caliper).

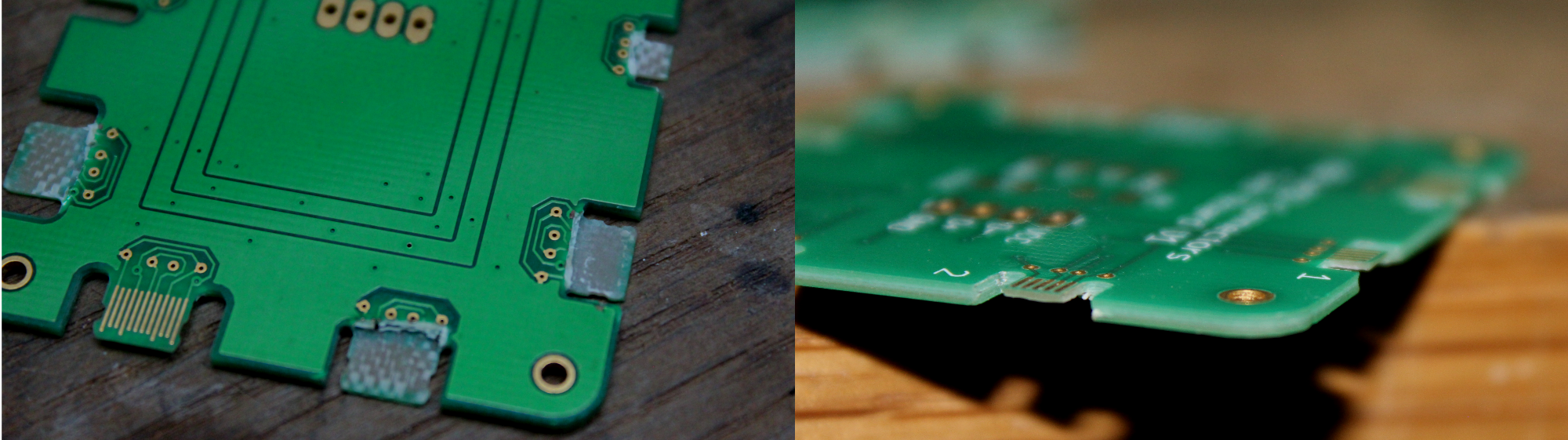

The footprint for the PCB connector type C is two sided, because the reversibility of the real connector, you can plug it either way. On the other hand, the real USB micro b is only one way, but my first footprint for that connector were two sided, that means that if you connect a USB micro b cable to that connector, in one side it does connect with the pads of the connector, but on the other side, the plug has a metallic surface, so all the pads are shorted together. That means that it could short circuited the USB supply and if there is no overcurrent protection it can potentially destroy my laptop (I seen some example of that).

I was scraping the PCB, thinking that I could not prove the reversibility of the connectors when I realized that it could cause the short circuit. of the USB, so my annoyance turned into happiness. I still could not test the reversibility of the connectors, but at least my laptop was safe. And at the end the test was successful and i was prepared to do the real prototype.

By the way, the test results were that the tighter the connector the better. So my conclusion was to make the cutout for the connector as small as possible to add more grip to the plug and maintain the cable attached to the PCB, and also make the cutouts a little bit longer considering that the drill doing the cutouts is round and can not do perfect corners.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.