Ok, time has come to assemble the whole thing together.

First, screw the bases to the table.

There is no need for super-precision here, the upper halves of the bases are adjustable. The screws protruding from the lower bases help fix the upper halves in place, after the whole thing is squared.

Now install the upper halves and the legs.

Not fixing them tightly yet, will do after the whole thing is adjusted. There is a lot of move to them, some 5-10mm.

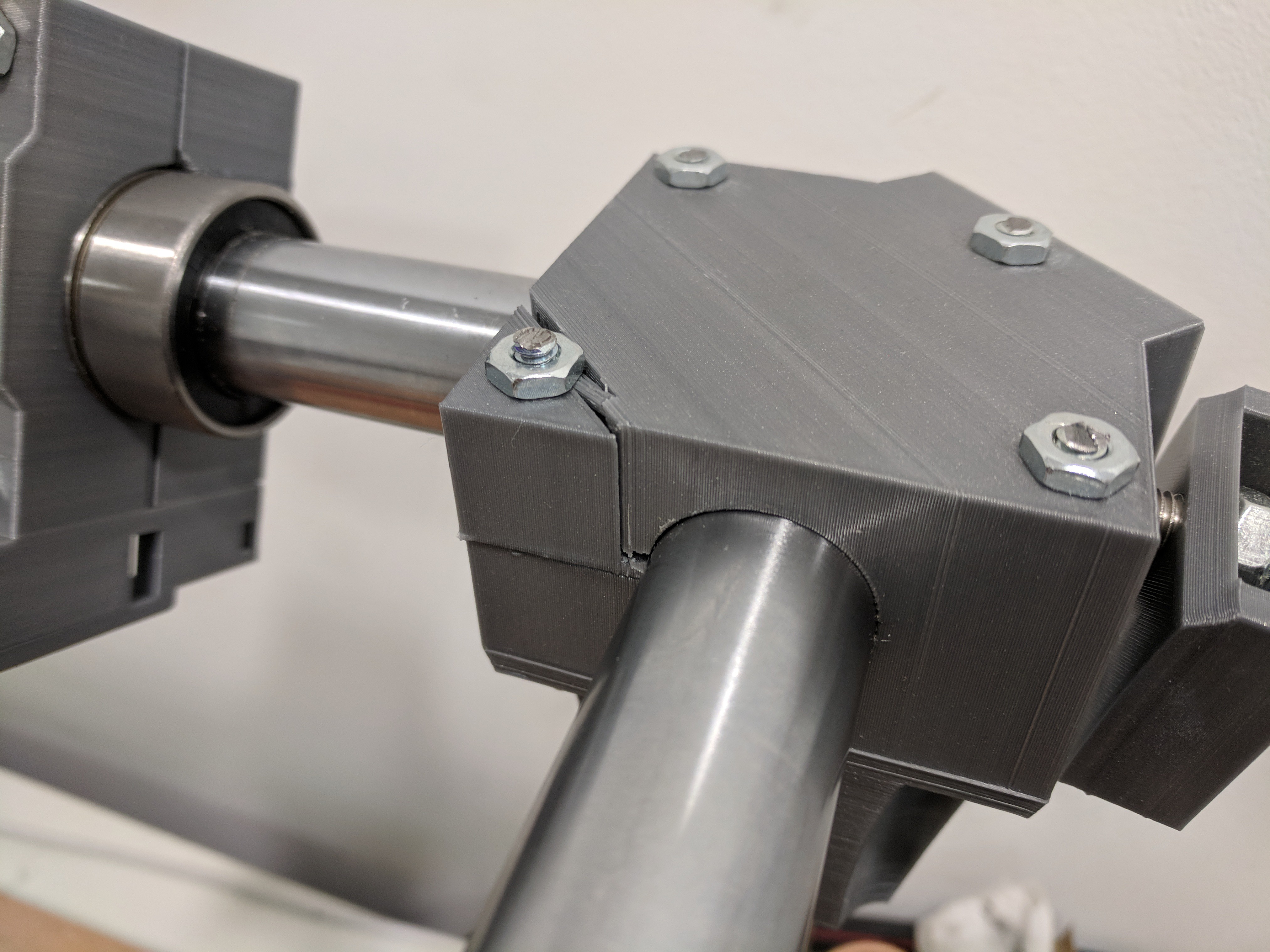

Now installing the gantry and tightening it.

And OOPS, one of the corners broke when tightening.

From examining it, the problem is the print orientation. The stress is applied along the lamination lines.

The solution to this is to re-make the corners so that they print lying down. For that, each corner has to be remade - I'll cut it in half so that there are no overhangs and it can be printed easily. The extra benefit of this is that the design becomes much easier to assemble: lay down the lower halves of the corners, then the bars, then the upper halves of the corners.

Stay tuned. Each corner now takes 17 hours to print, so it's a few days until I'm able to continue.

Alex Gontmakher

Alex Gontmakher

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.