The objective of the design is to be primarily 3D printed due to time constraints. The unit will support two identical magazines. One magazine will be utilized as a battery to power the on-board electionics, and the second magazine will be used to store ammunition / position the ammunition for the firing mechanism.

Electronics / Firing Mechanism

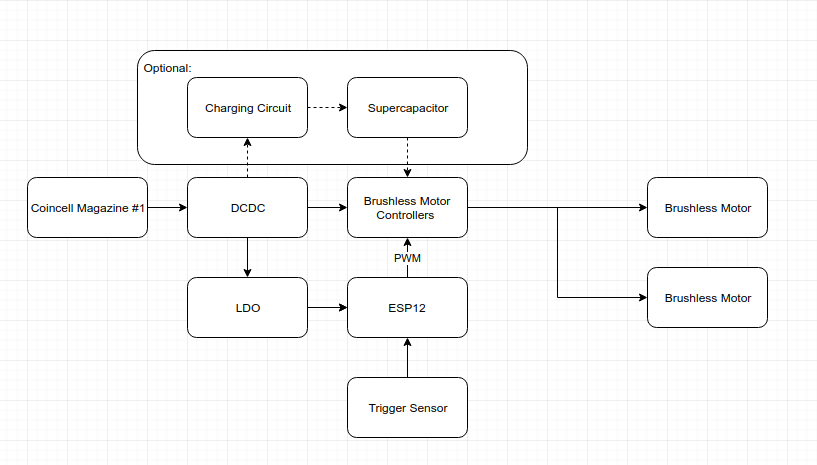

The unit will be powered by stack of coin cells (CR2032s) batteries which typically have a high internal resistance and HATE large loads. Therefore, the power supply for this unit I'm hypothesizing will use a DCDC converter to translate the high voltage from the cell stack to 12V and reduce the current draw on the cells. A super capacitor could also be potentially utilized to prevent damaging the cells.

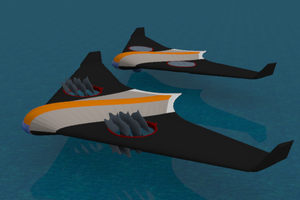

The firing mechanism will be archaic in design and is stolen directly from my nephew's Hot-wheels matchbox car accelerator. As you might have already visualized, it will consist of two rotating masses covered in a material (such as rubber) which will provide a high coefficient of friction and (hopefully) provide a decent normal force to the cell via compression. I'm hoping the compression of the material will be enough that a tensioning mechanism will not be required to provide adequate normal force for the rotating mass and enough that a coin cell will not jam the firing mechanism.

The accelerator will be powered by the cheapest reasonable brush-less motors I can find. The fire control unit will be responsible for detecting the trigger has been pulled, activating the accelerator, and (likely mechanically) feeding a cell into the mechanism from the magazine. I'll probably use a ESP12 to generate the PWM signal required to control the brush-less motor controllers. (WHY?!@!@!#@!# ....because I have a million of them and anarchy.)

Links

The 3D files for the test jig can be located here: https://cad.onshape.com/documents/acbb7506f4f200513fd2bd19/w/e96497426bc405d07a19c729/e/f35c24153e637982e52c80ff

Tyler Berezowsky

Tyler Berezowsky

adriancubas

adriancubas

ken.do

ken.do

sean d'epagnier

sean d'epagnier