Latest Demos:

Overview of the onboard Synthesizer:

2018 HaD Prize Official Entry Video:

Many engineers, hackers, and makers have focused on the hardware implementation of creating a musical gadget of some kind. The challenge is that most of these instruments are heavy on hardware and light on usability as an actual instrument.

In the digital instrument market today there are very limited options for MIDI woodwind controllers. This project aims to bring a DIY opensource version up to the plate that the average maker can create and play. This could eventually be a great project in school curriculum for those technologically inclined musicians beyond the standard robot classes.

We are flooded with MIDI keyboards, matrix controllers, drum sets, but those who wish to harness the dynamic response of breath are left lacking in options. This open source instrument should be a source to many hackers who would like to implement an intuitive and configurable instrument.

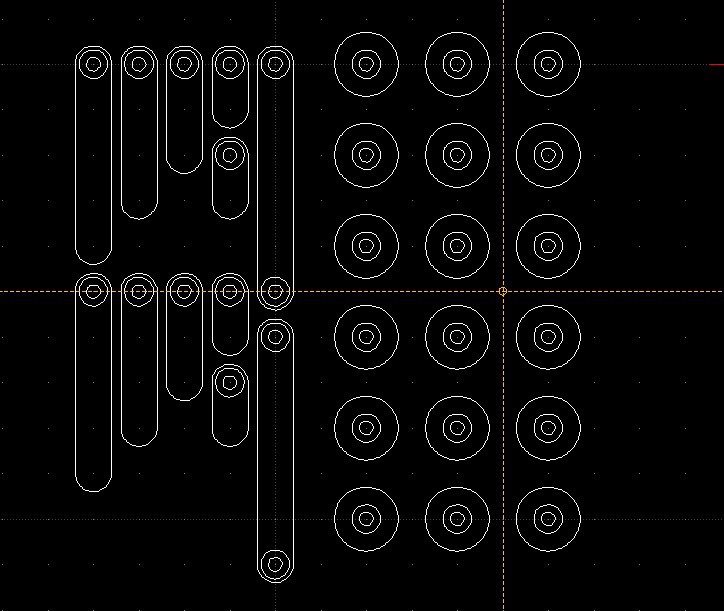

In the end I wish to offer up kits (laser cut files and pre-programmed microcontrollers) to those who would like to build their own instrument.

Project Goals:

- Create an electronic aerophone (MIDI woodwind controller) that is intuitively playable.

- Easily re-created by the average maker and is not just a music making gadget.

- Inexpensive and easily adaptive to new sensors and fingering modes

What is an Electronic Woodwind Controller?

Electronic instruments, and even MIDI instruments have been around for decades now, but usually you see developments in keyboards, drum pads, and matrix controllers. Several companies have made woodwind controllers to include Yamaha, Roland, and Akai, all stemming from the original concepts from pioneer Nyle Steiner. The EWI (Electronic Woodwind Instrument) and EVI (Electronic Valve Instrument) were the products of Mr. Steiner's genius. Akai still produces instruments from the original concepts introduced in these first designs.

Modern day computers have provided MIDI controllers a vast powerhouse for synthesis and sound design that can't easily be reproduced by stand alone instruments.

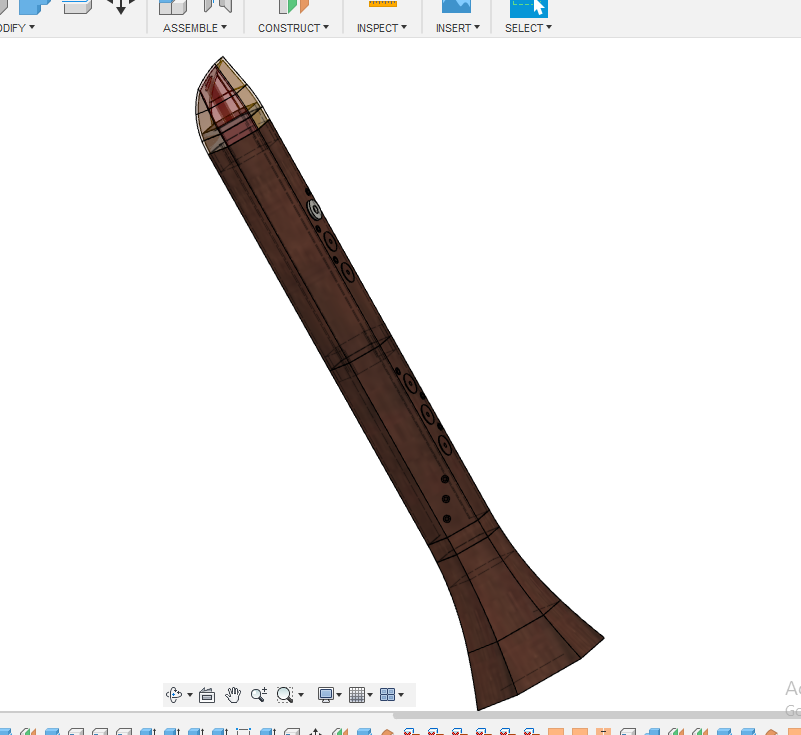

Nearly three years ago my first prototype was born, and recently the project has been picked back up to drive it to completion. This project is creating an Electronic Aerophone as a variation on the EWI, and will be released to the community once development has reached an adequate level of completion.

The following attributes are unique to this project, and help bring this controller to a new level:

- Custom fingering mode, specifically designed to combat the 'glitch' issue of the Akai EWI

- IMU integration for modulation and pitch effects

- Analog outputs for Eurorack Systems

Technical Details

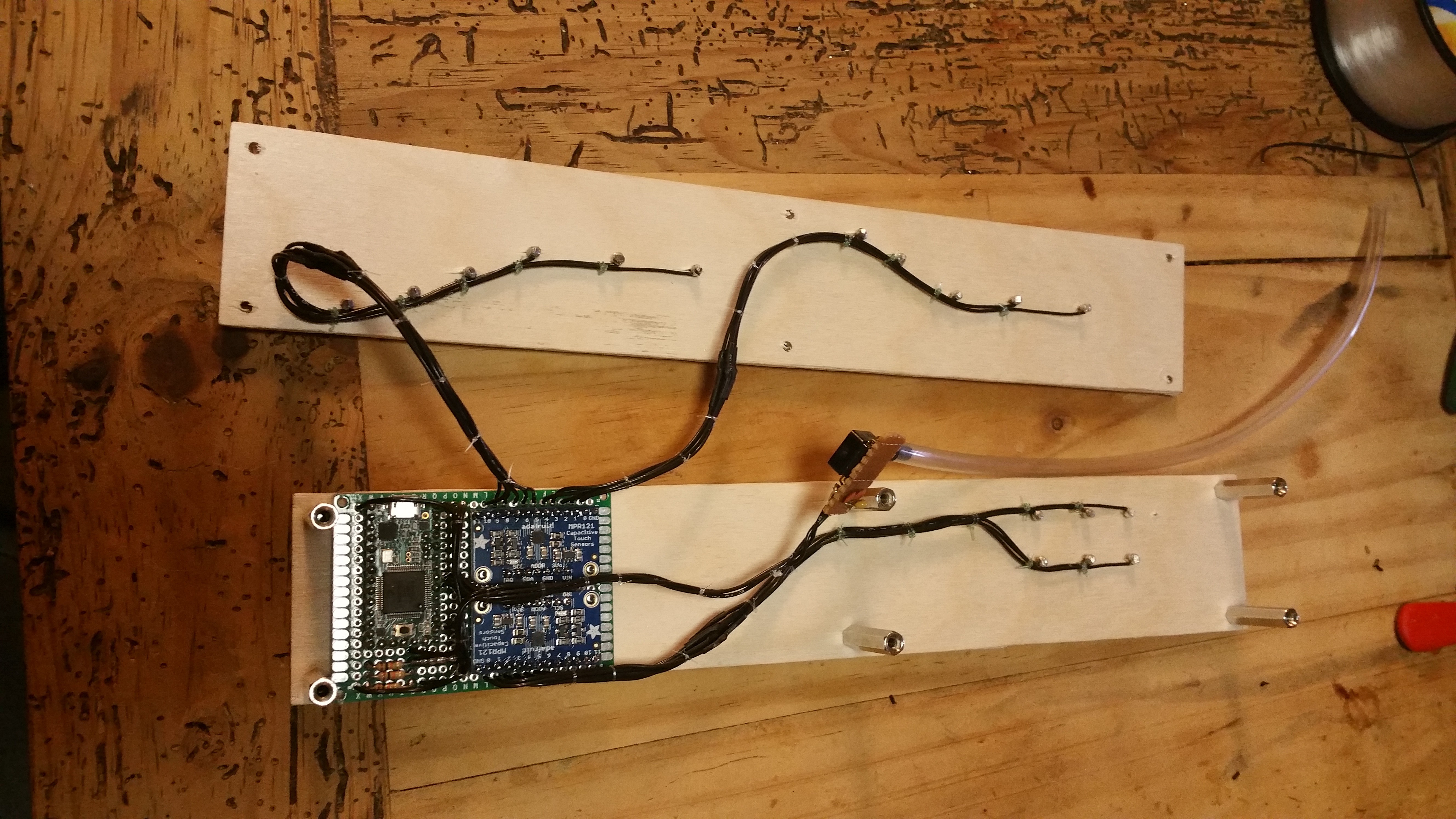

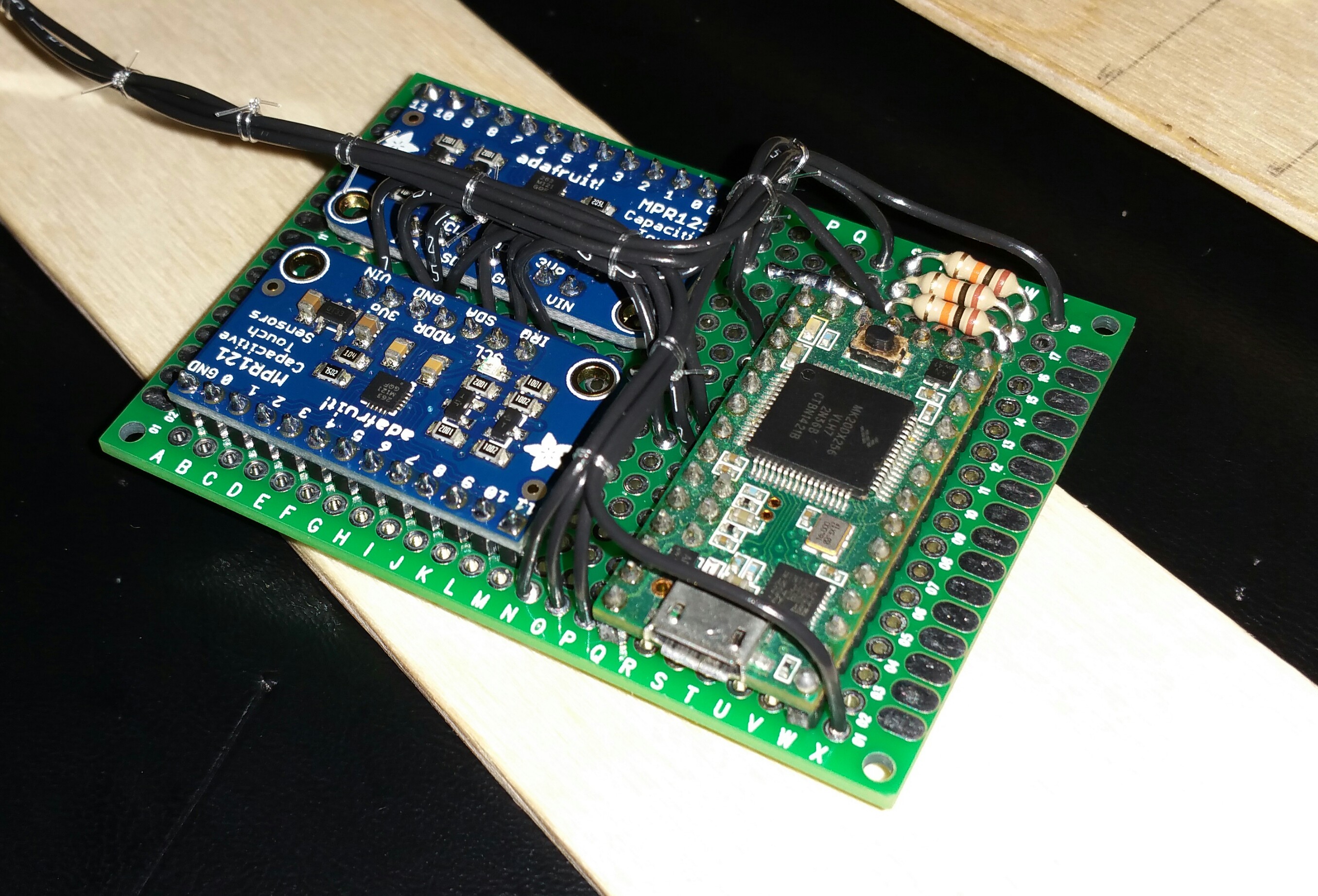

The controller itself utilizes a Cortex M4 microcontroller board (the venerable Teensy 3.2 from PJRC), two MPR121 touch controllers (24 total channels of capacitive touch capability), and a pressure sensor, an OLED screen, and some other various discreet components.

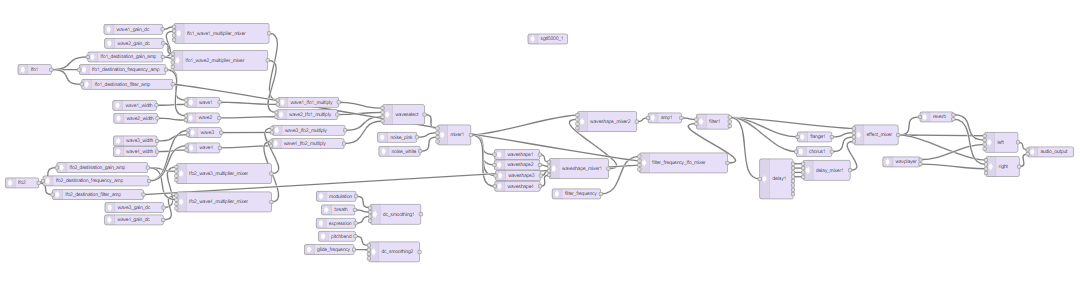

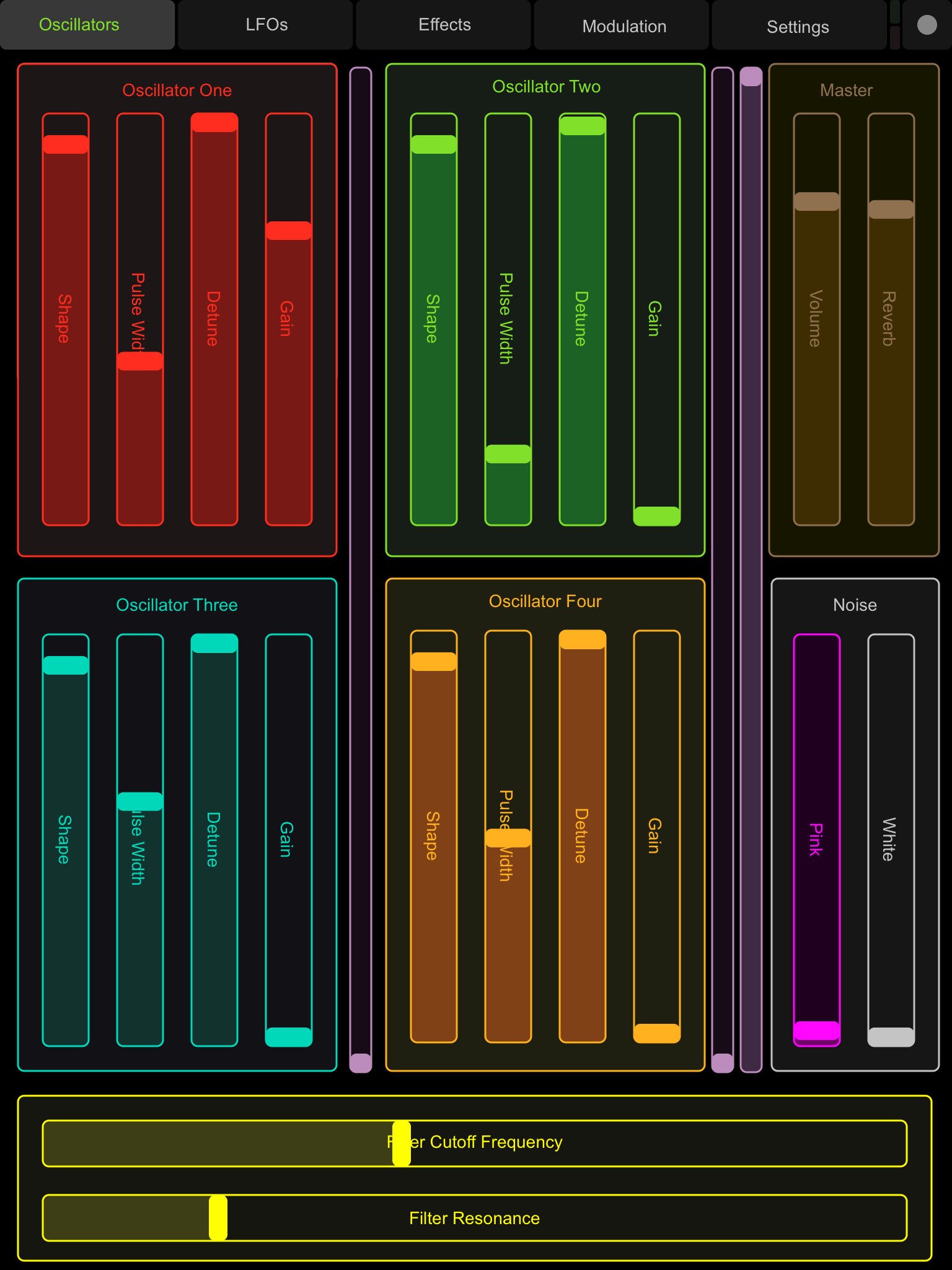

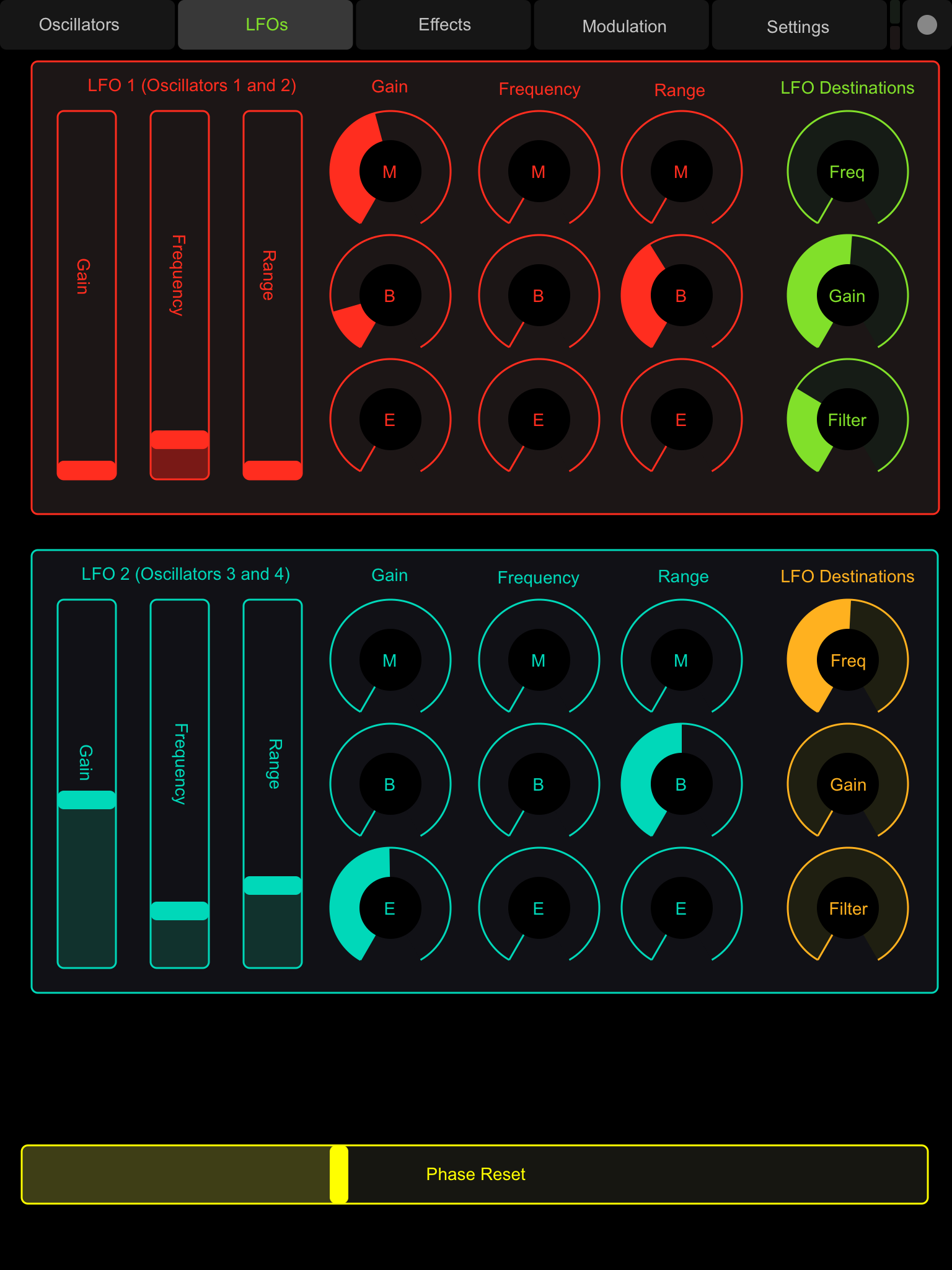

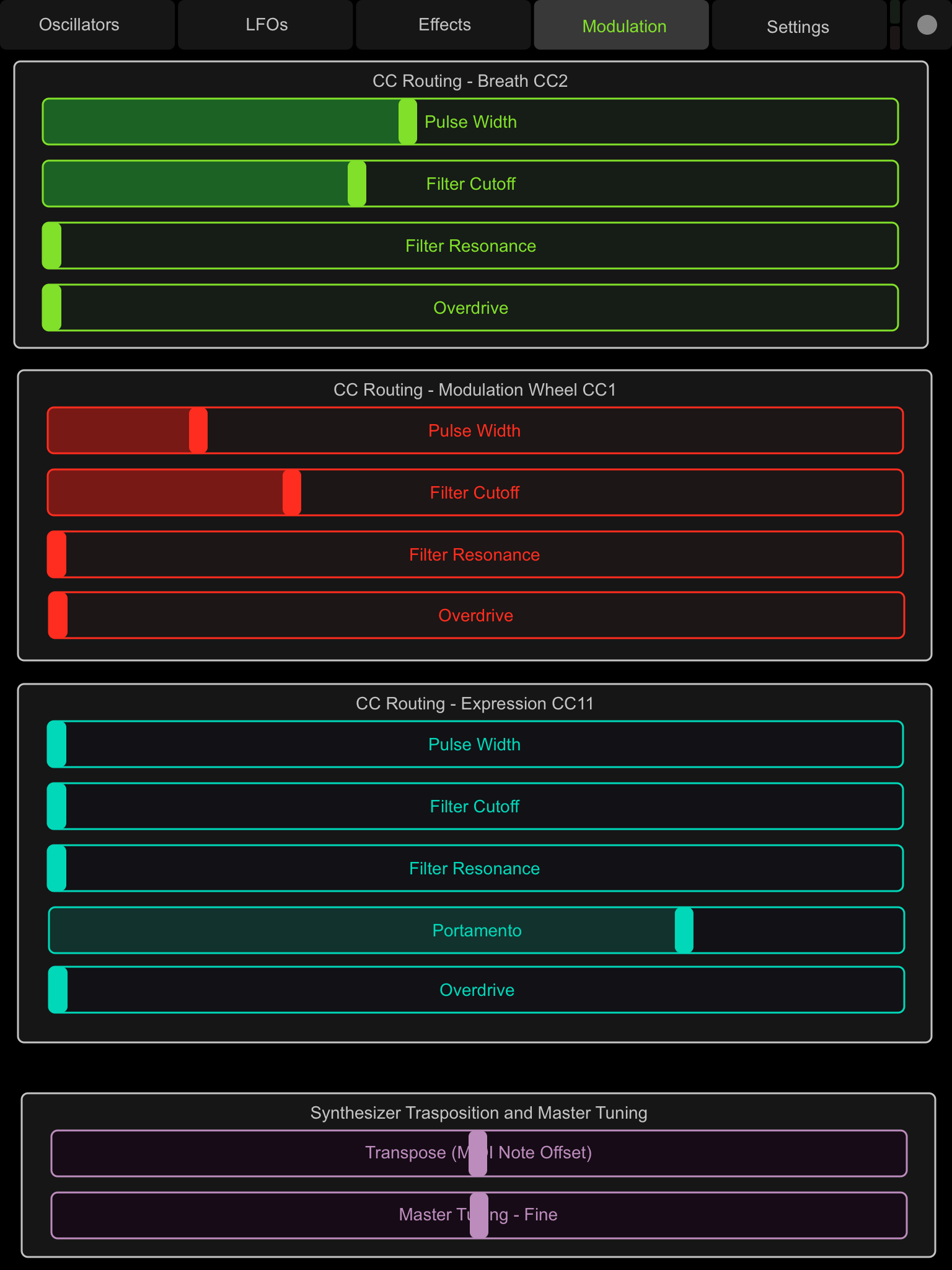

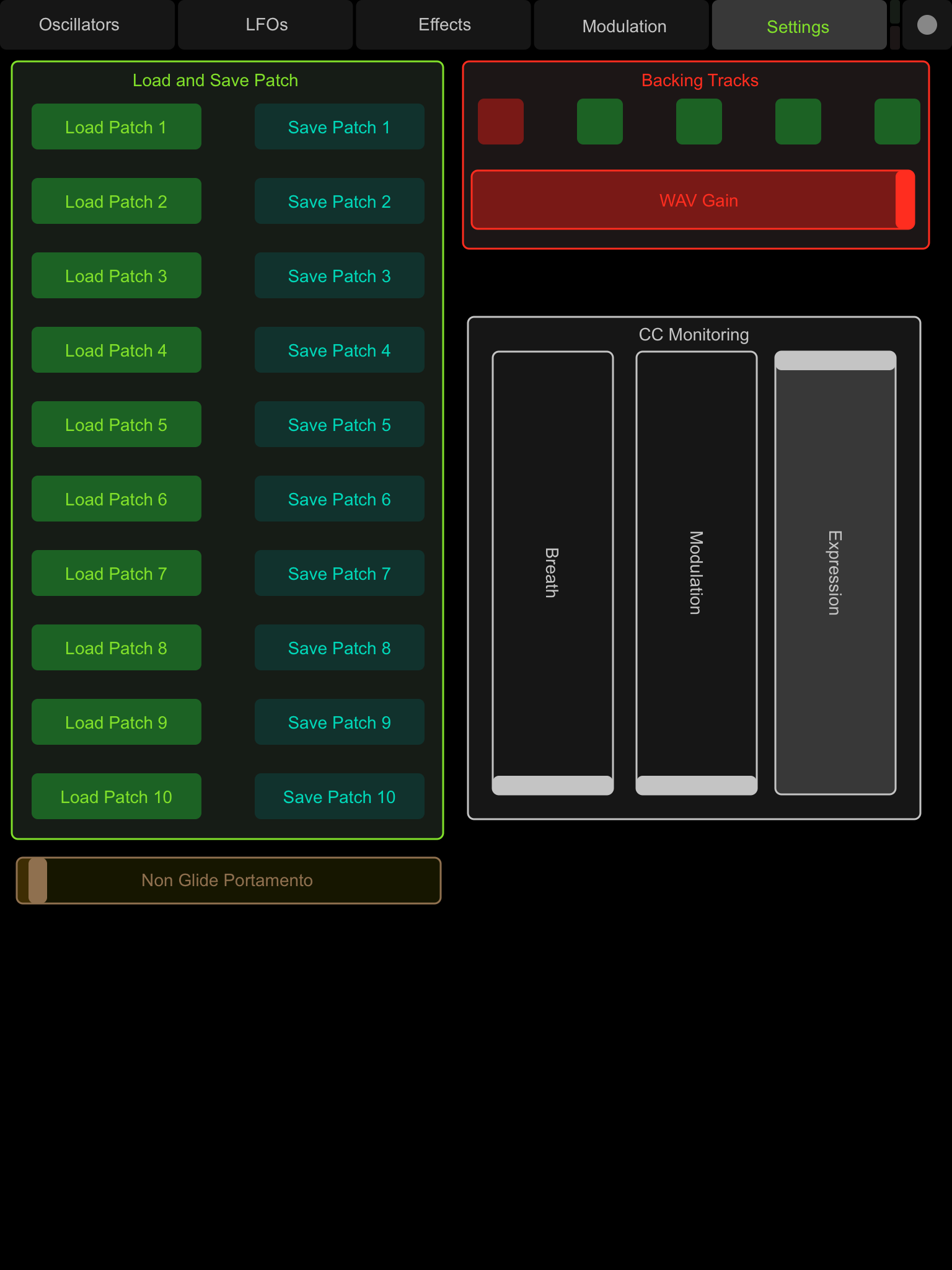

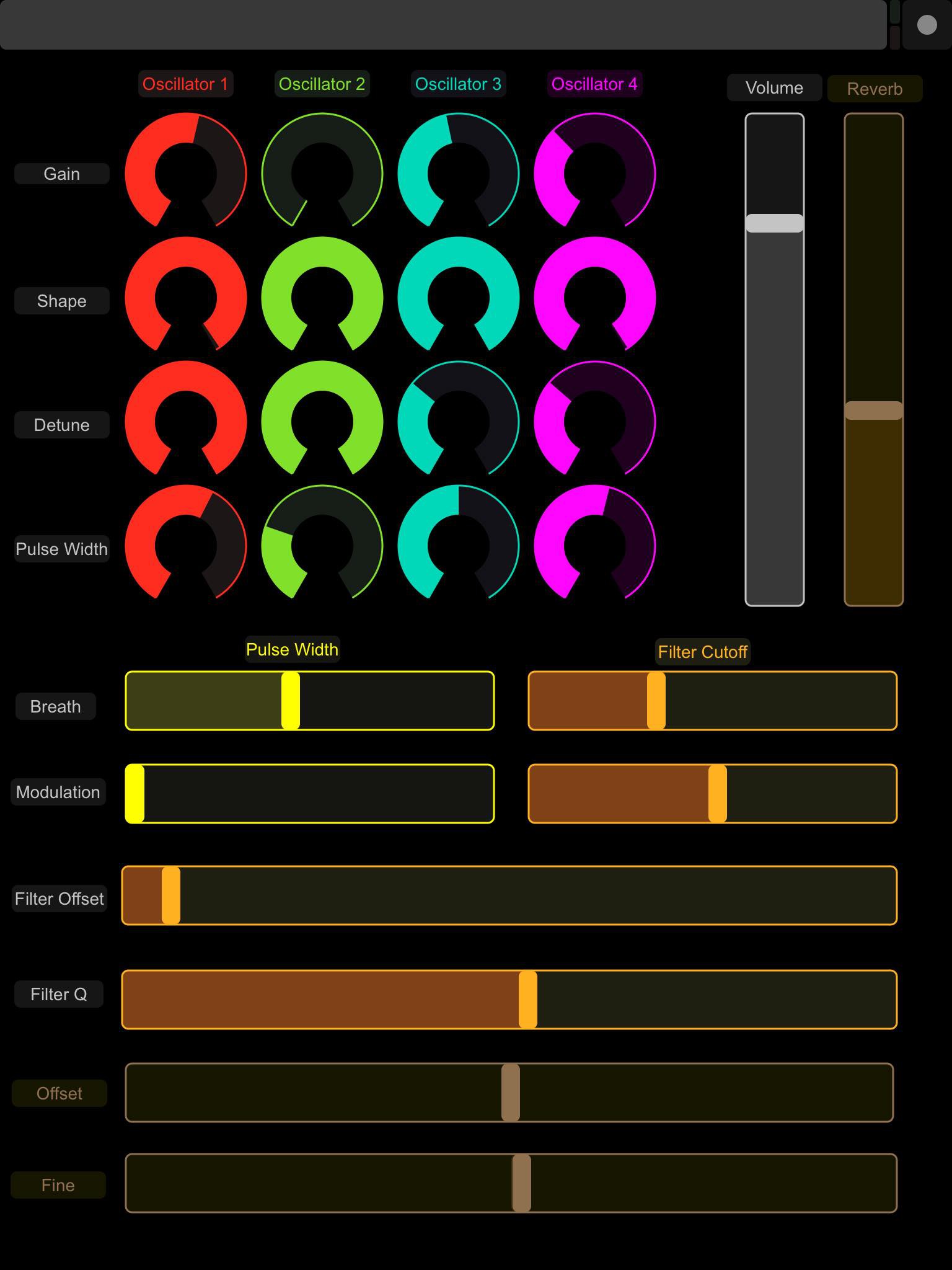

Sensor data is fused together and sent via a MIDI stream to a computer for sound generation, or actualized into audio via the onboard synthesizer (currently a DSP-G1, but will probably change)

Code is released under the GPL.

Interesting Project Logs

- https://hackaday.io/project/2992-the-open-woodwind-project/log/152531-the-challenge

- https://hackaday.io/project/2992-the-open-woodwind-project/log/146199-main-loop

- https://hackaday.io/project/2992-the-open-woodwind-project/log/147002-prototype-working

Current Status

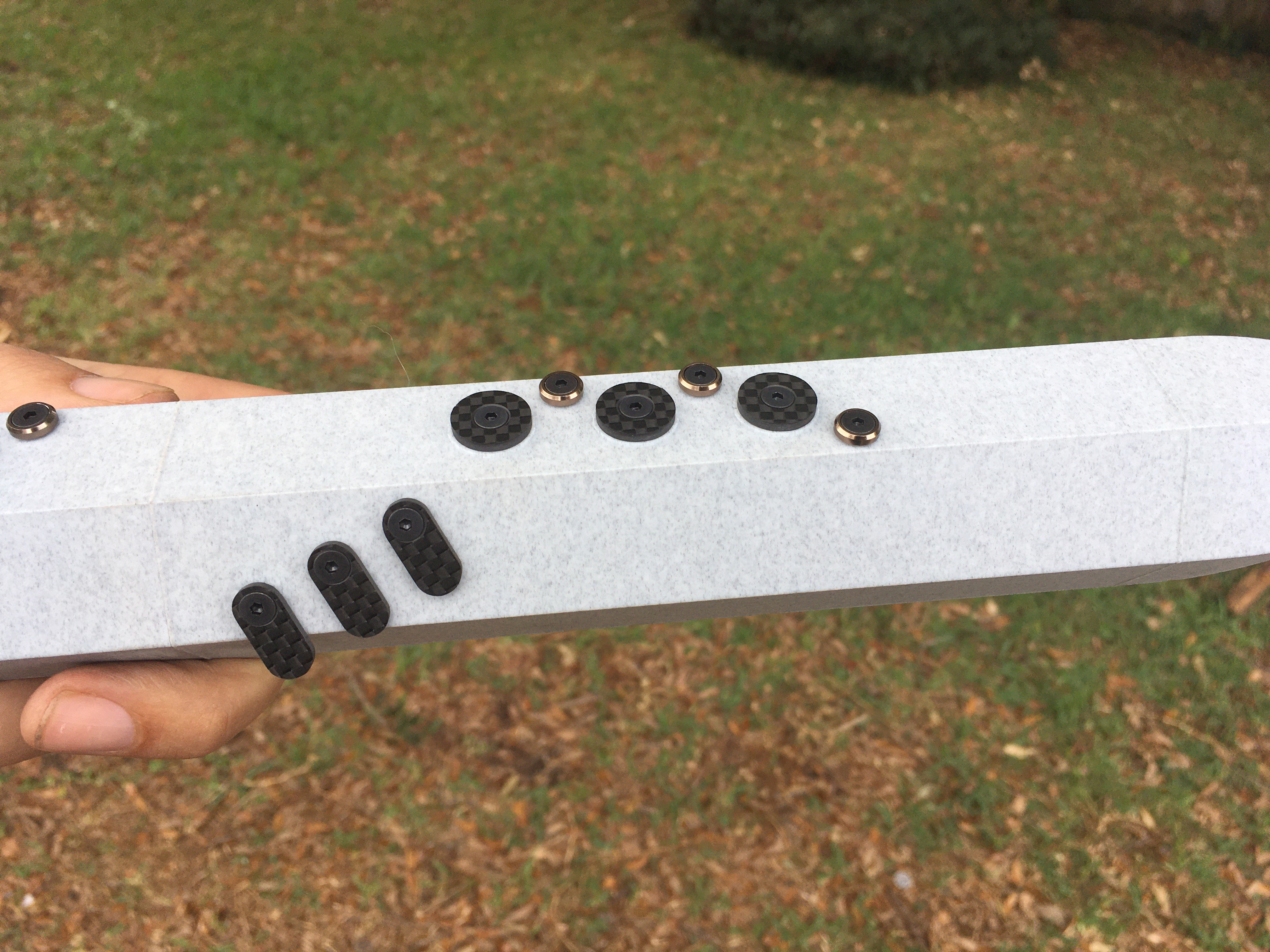

- Second Prototype - 95% complete - Playable

![]()

![]()

J. M. Hopkins

J. M. Hopkins

toxi

toxi

Maarten Janssen

Maarten Janssen

Michael Erberich

Michael Erberich

Johan Berglund

Johan Berglund

Heya, I love this project and just completed my take on the version here: https://cdn.hackaday.io/images/6105481540155286021.png. I'm a beginner to microcontrollers so I didn't worry about the onboard synth, wireless MIDI or any of that for now, just enjoying it pugged into your Reason patch. I did wonder, if you'd ever had a chance to put together a fingering chart - I'm not much of a musician and not exactly sure how the registers, octave breaks, and in generally, efficient fingering, are all supposed to work. Thanks for putting this out there!