Overview

When starting #Goliath - A Gas Powered Quadcopter, one of the goals was to use off the shelf hardware. After looking at propeller/rotor from traditional aircraft suppliers two issues became readily apparent. The first issue was that the cheapest rotors start at about $300, so a complete would be over a grand. This would have overly expensive for a prototype vehicle that broke three rotors in the first 50 tests. The second issue was the the designs are closed source. The buyer is expected to provide the manufacturer a engine/airframe combination and the manufacturer designs the rotor to match, and does not provide the buyer the details.

The goal of this project was to provide the tools and design instructions for other makers to build and/or design their own inexpensive open-source propellers/rotors. These goals have been met and the project documentation allows the user to build their own propellers/rotors for as little as $20-$40.

Design

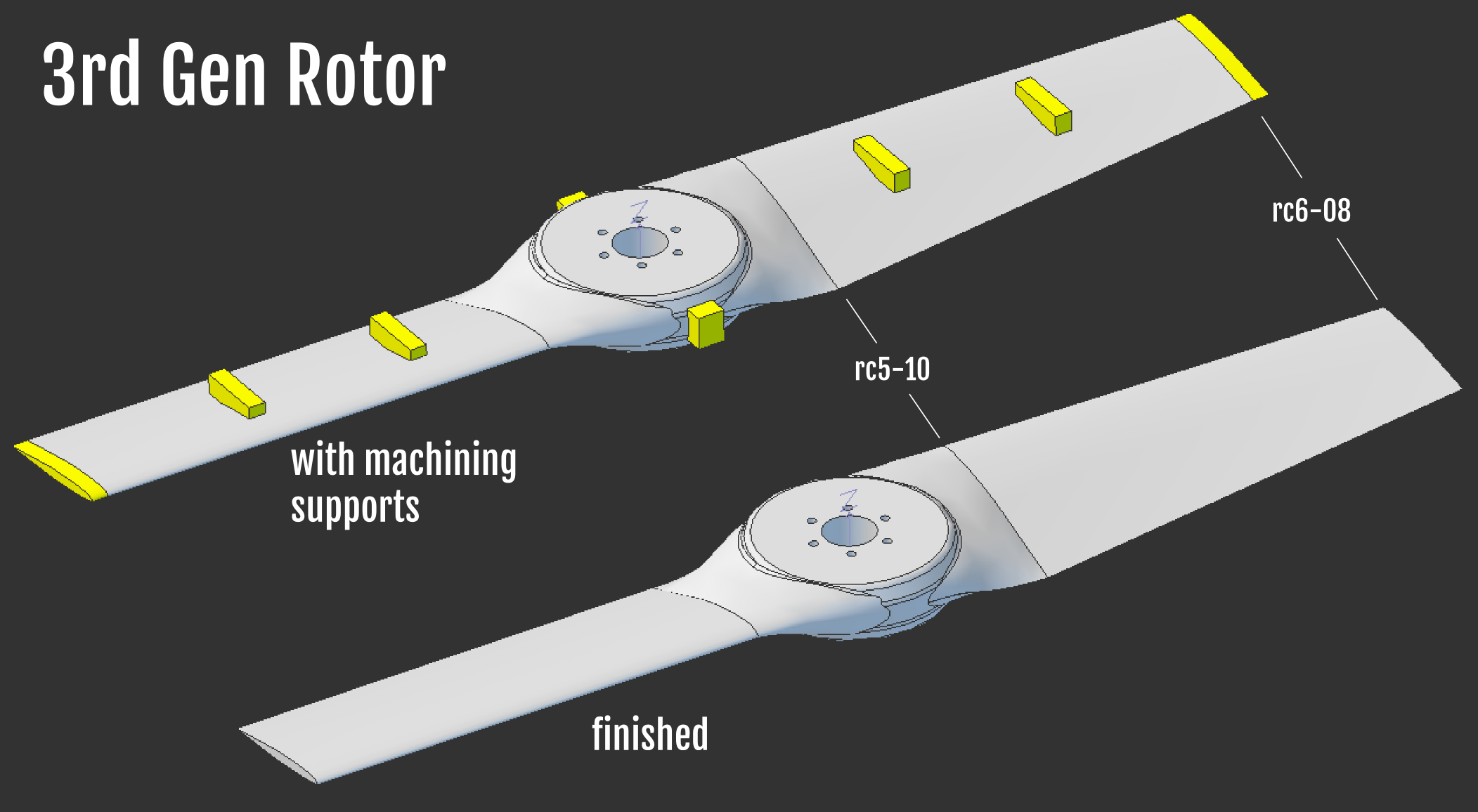

There are a couple of rotor designs included in the github repository available for anyone to build. However if you need to design your own propeller from scratch, the repo has what you need as well. The first step is to determine the necessary propeller/rotor characteristics. The Rotor Blade Element Analysis (RBEA) code can help in designing the right propeller characteristics. While it's not required, a basic understanding of blade element theory is helpful in applying the code. Once you've found a design that can provide the required thrust at the desired power and RPM setting, a CAD model can be built for generating the CNC tool paths.

Construction

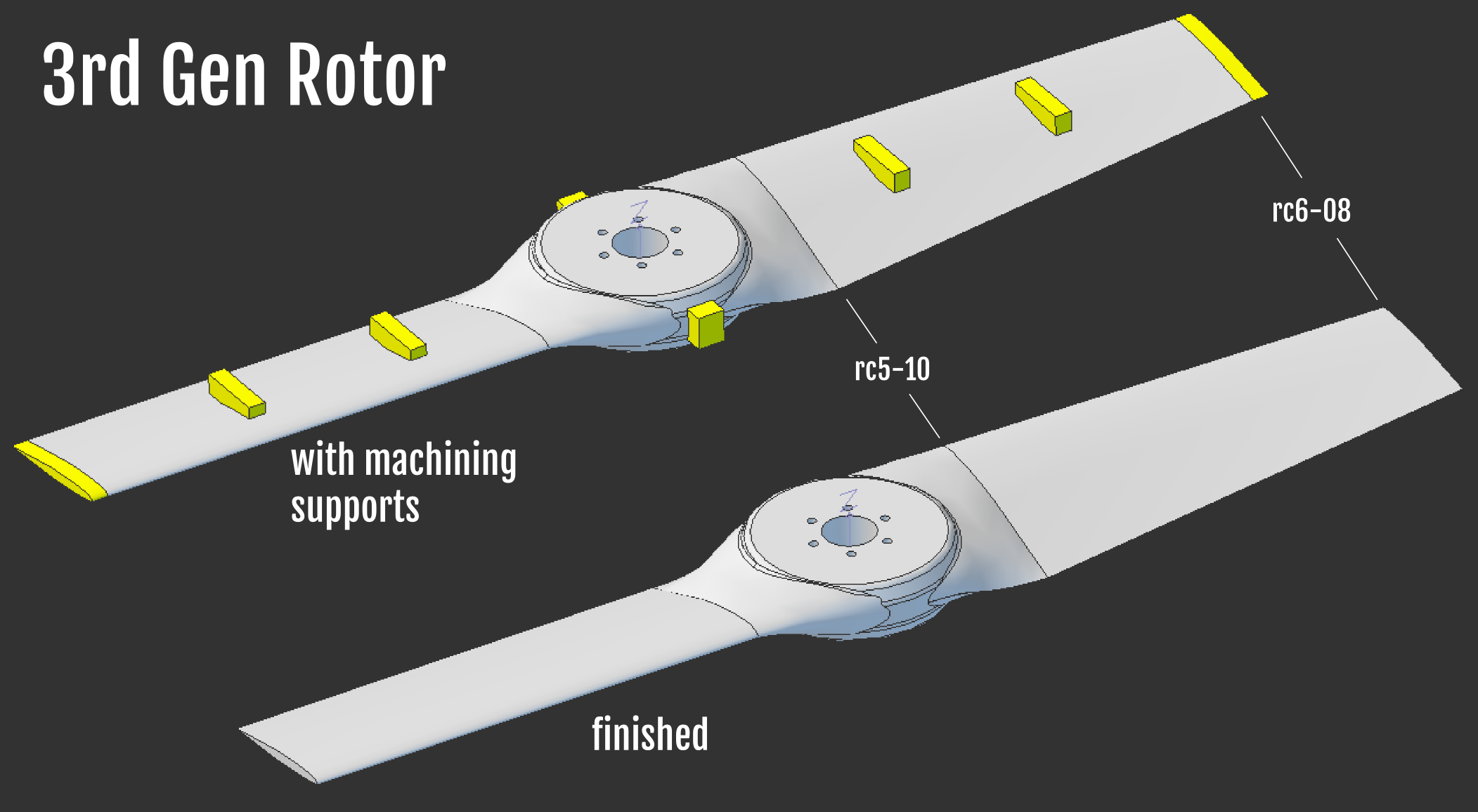

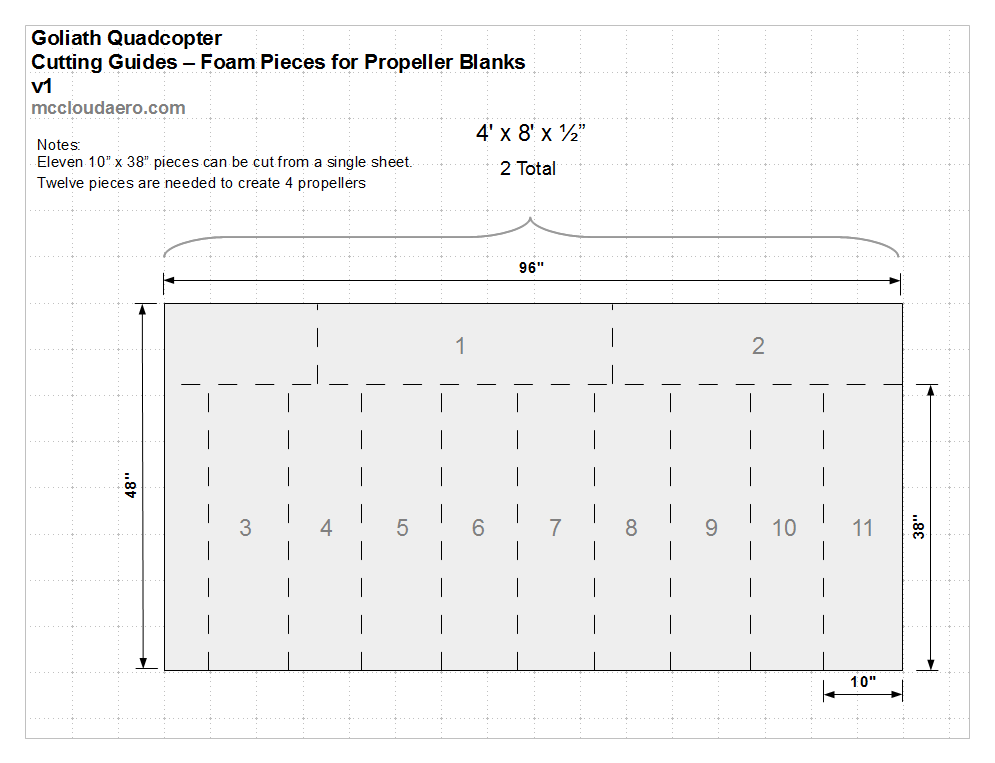

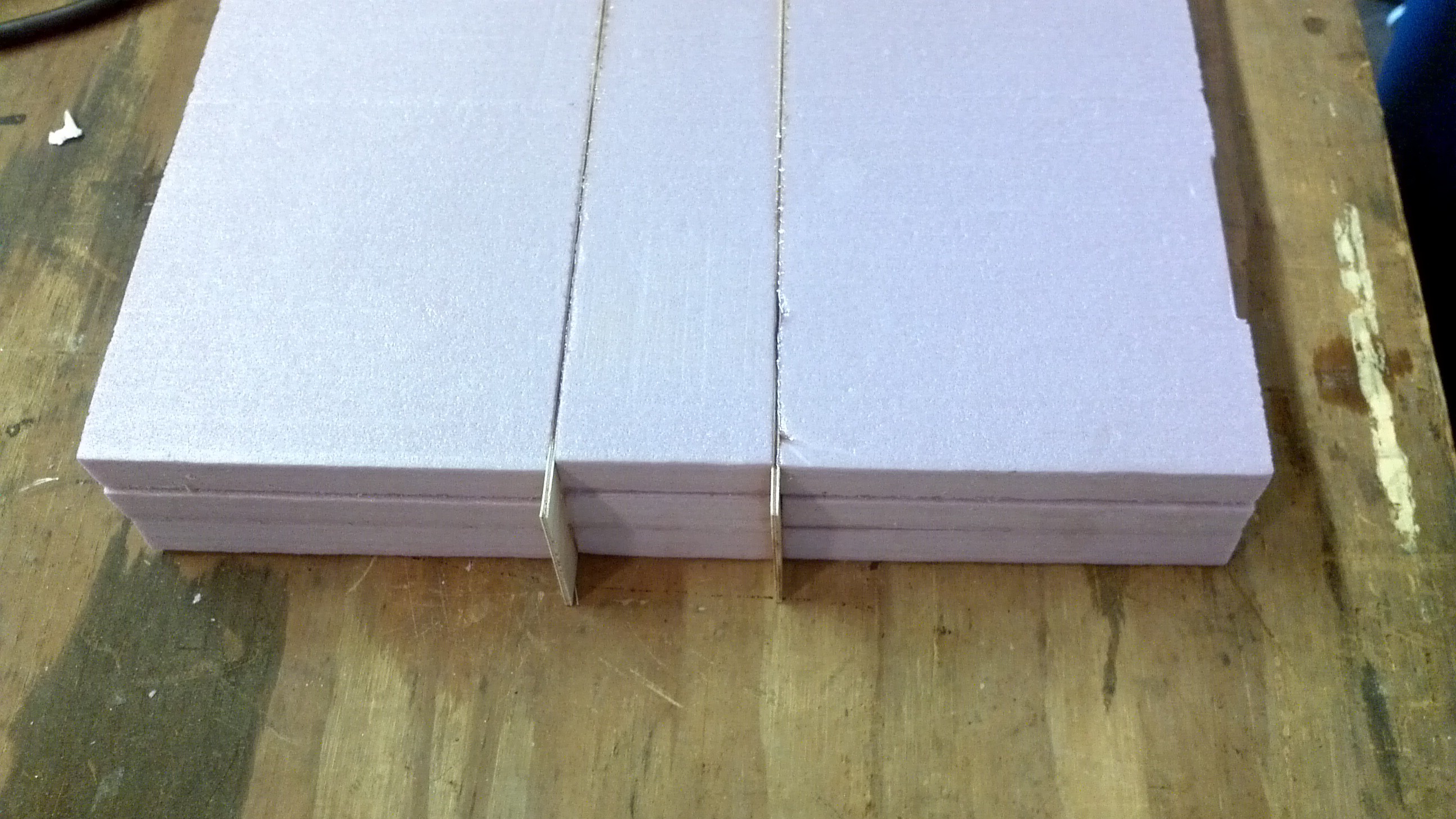

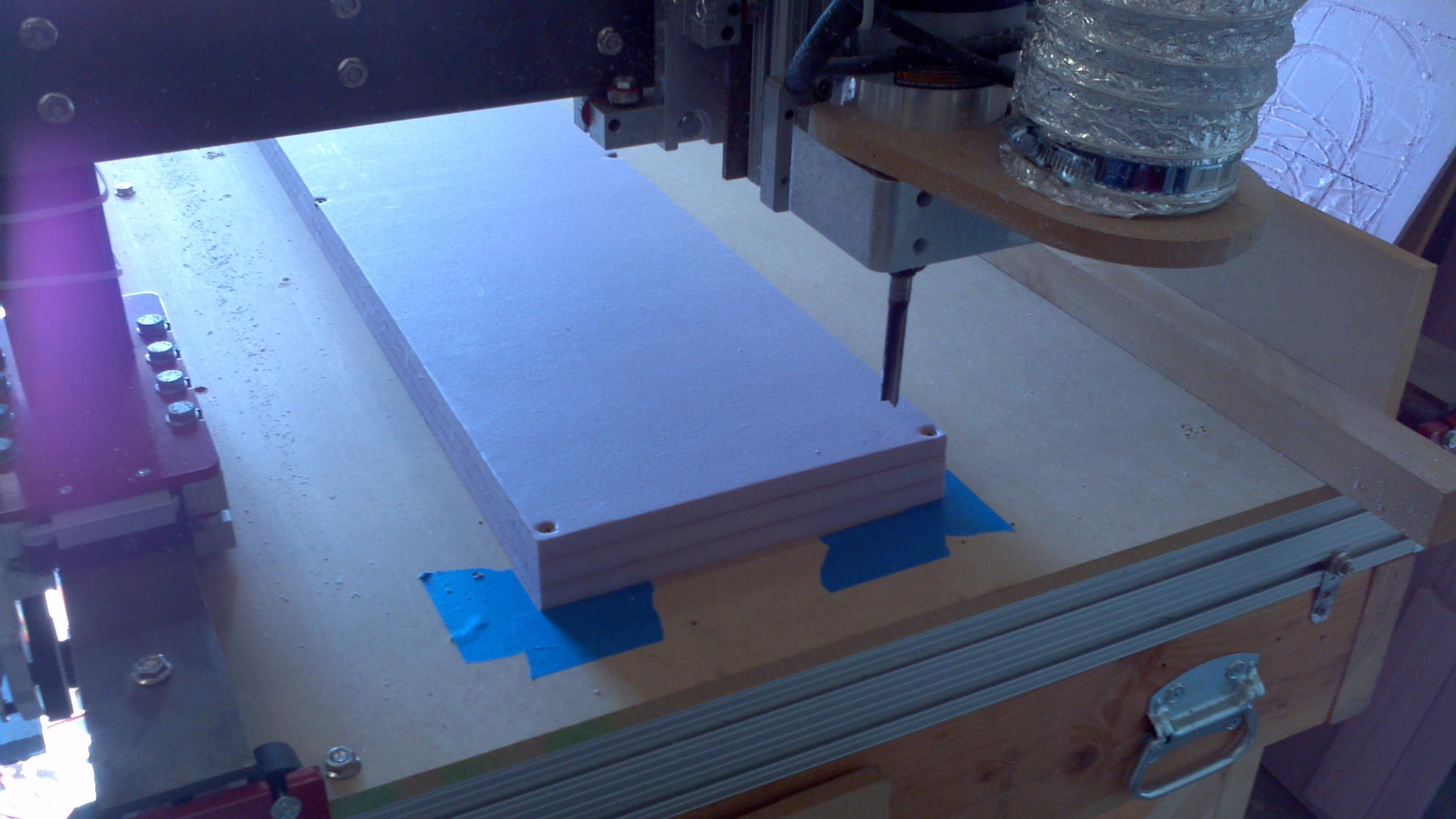

The propellers/rotors are built using a foam core composite method. This type of method has been used by model aircraft builders to build lightweight wings. Typically in the past, the foam cores are constructed using hot-wire cutters and 2D airfoil templates to guide the hot-wire. This technique is limited as it can be difficult to impossible to build complex or twisted cores.

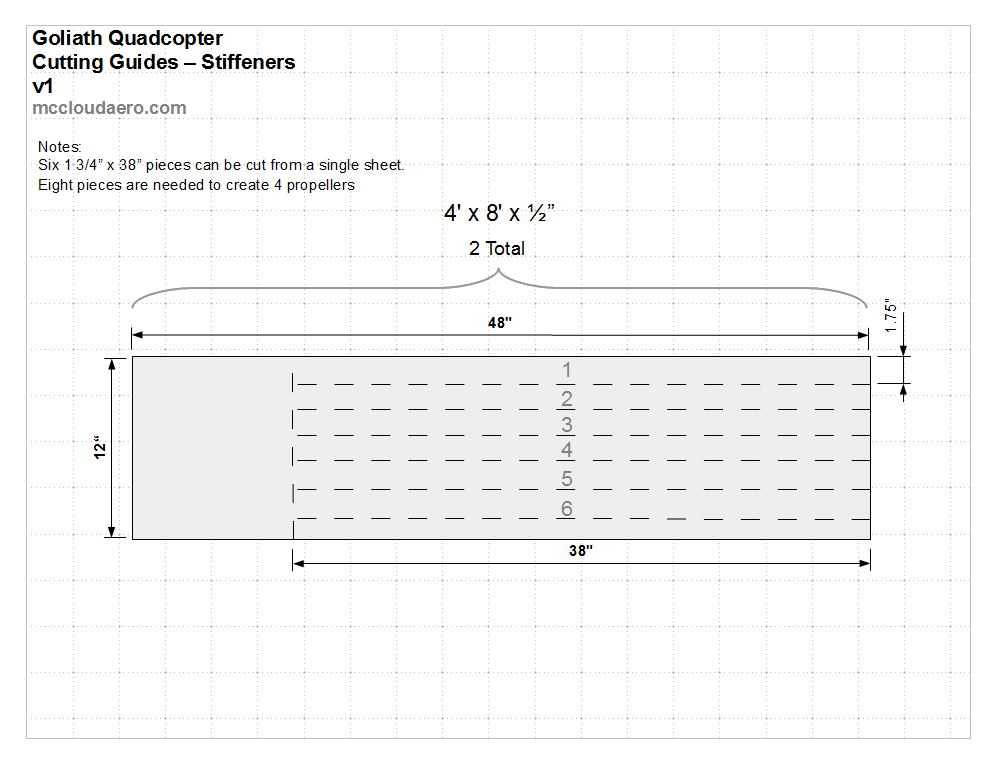

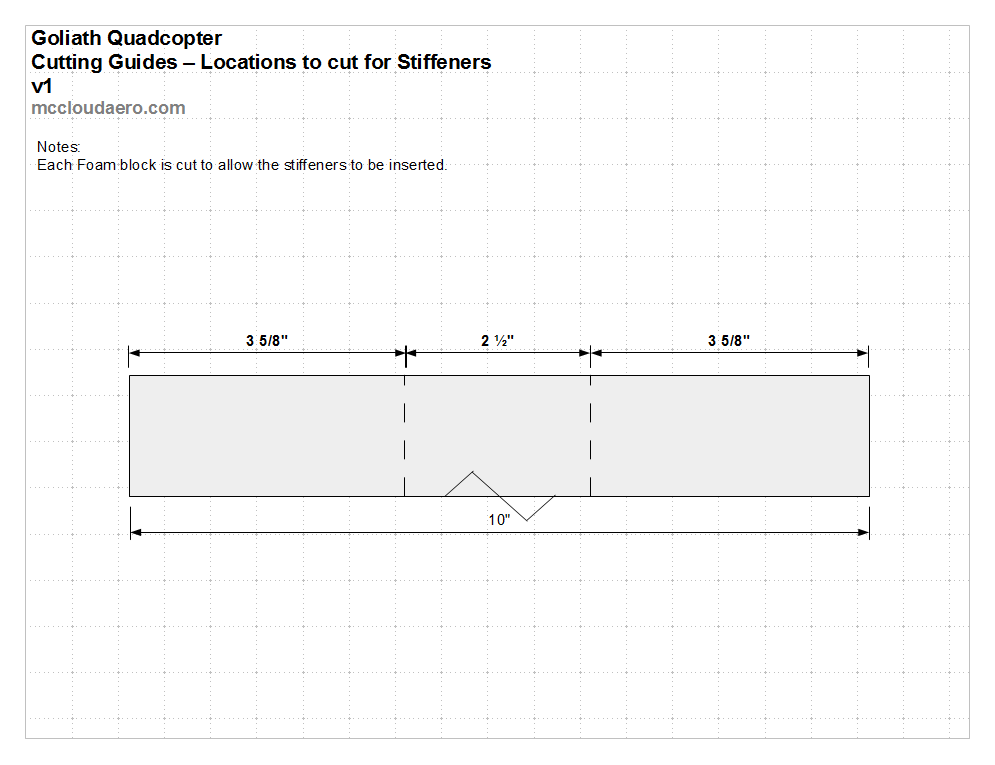

CNC routers allow complex cores to be built easily and have features that can't be done with hot-wire cutters such as embedded stiffeners. This project outlines the process of how to construct inexpensive foam core composite propellers/rotors.

Peter McCloud

Peter McCloud

Alain Mauer

Alain Mauer

Meksim

Meksim

dannyvai

dannyvai

Khalilone62

Khalilone62

HI,

this is regarding the gas drones, Recently i got a problem statement stating building a multi copter for lifting 30 kg payload initially we planned for battery powered drones but gave it up as it wasn't much suitable for lifting heavy payloads so it'll be help full if u help about the project like what is best possible way for lifting the payload the type of controlling system, the type of engine, power transmission to propellers, which is better the engine way or the battery method, the kind of propellers etc.