-

3rd Gen Rotor Design

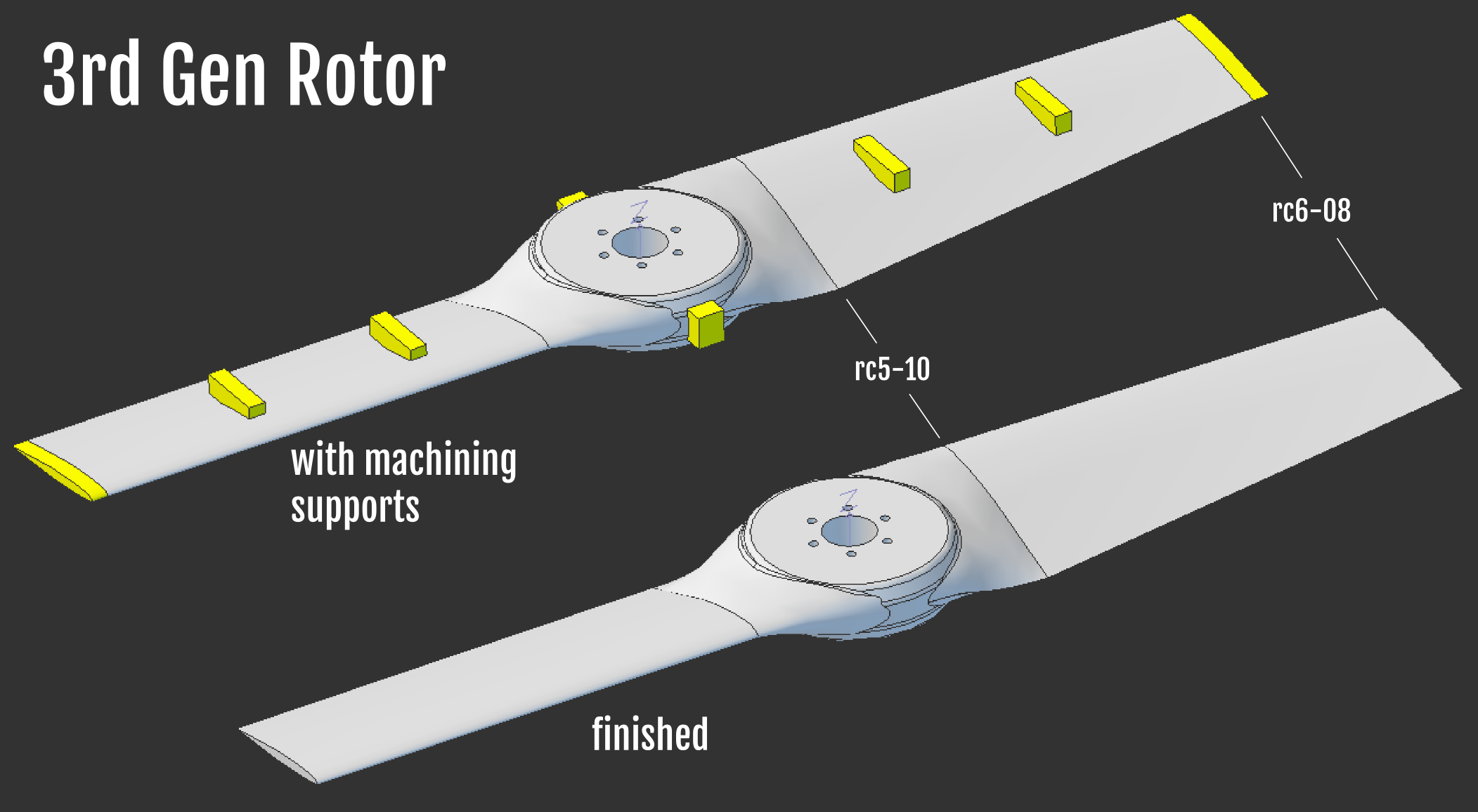

03/24/2017 at 03:25 • 0 commentsThe design for the 3rd gen rotor has been finalized and is shown below. The upper portion of the picture shows the rotor with the machining supports present. This is what the rotor looks like coming out of the CNC Router. The lower portion of the images shows the finished rotor with the supports removed. The airfoils for the tip and the root are highlighted.

![]()

-

RC series Airfoils

03/02/2017 at 05:09 • 5 commentsThe previous rotor designs used generic NACA 2412 airfoils. These airfoils were developed over 80 years ago, but they are well documented and good general purpose airfoils. However to get the most thrust, airfoils specifically designed for rotors are required. Searching around led to the RC series of airfoils

RC series airfoils

The RC series of airfoils are specifically designed for rotorcraft applications. The naming scheme is RC(X)-YY where X is the number in the series and YY is the airfoil thickness in percent chord. Two of the airfoils, designed for the inboard section of rotor blades are the RC(4)-10, RC(5)-10. Data for these airfoils is found in:

The other airfoil is the RC(6)-08 airfoil, designed for rotor tips. Data for this airfoil is documented in:

Applying the new airfoils

Previously the rotor.py code was only written to use a single airfoil for the entire rotor. Recent updates allowed using two different airfoils, one a the tip and the second at the root. Changing the tip airfoil from the NACA 2412 to the RC(6)-08 means a 25% reduction in the chord. Since the bending moments are low at the tip, the thinner section doesn't affect the structural strength significantly.

Changing the root airfoil from the NACA 2412 to the RC(5)-10 airfoil means a 17% thinner airfoil. It may not seem like much, but the bending strength scales by the thickness cubed. Keeping the chord constant and changing from a 12% to 10% thick airfoil means a 42% reduction in bending strength.

To keep a similar strength with the thinner airfoil, the root chord will be increased from 4.5 to 5.4 inches to keep the overall thickness the same at the root. This leads to a negligible decrease in aerodynamic efficiency, but a big difference in the structural design.

So how big is the difference?

Rotor hover performance is measured by Figure of Merit (FM) vs. Efficiency. Hovering isn't doing any useful work so efficiency doesn't really apply. The FM is the ratio of the required power vs. the ideal required power. The previous rotors had a FM of about 60%. Analysis suggests the new rotors using the RC airfoils will have a FM of 80%.

-

Rotor Blade Element Analysis (RBEA)

02/24/2017 at 04:20 • 0 commentsCode Updates

Recently, the rotor designs were re-visited to double check some of the design assumptions. In the process the code was polished up and some improvements were made.

Bug Fixes

Found that the code would not converge for some cases and the user wouldn't know. Not so much a bug as poor programming. Added logic to notify the user if the case doesn't converge

Improvements

Broke out the inputs into a file (inputs.txt), keeping the code cleaner. Additionally switched to using splines for the airfoil data instead of fits done in a spreadsheet. Added support for Mach and alpha airfoil coeffs vs just alpha.

Additions

Code for calculating blade moments

Python Code (repo location)

import sys import math import numpy as np import scipy.interpolate # Rotor Blade Element Analysis # Python Script for determining Rotor Performance using Blade Element Theory # Definitions # theta - The physical angle the airfoil is rotated from the plane of rotation # phi - The change in flow angle due to the induced airflow. Makes the angle of attack smaller # alpha_rad - The effective angle of attack the airfoil experiences # alpha_rad + phi = theta pi = math.pi # Read inputs file execfile('inputs.txt') # Determine airfoil method try: airfoil_name except: # airfoil_name is not defined, see if tip & root airfoil names exist try: tip_airfoil_name except NameError: print 'Neither airfoil_name nor tip_airfoil_name in inputs file' print 'Exiting!' sys.exit(1) else: # tip_airfoil_name exists, see if root_airfoil_name exists try: root_airfoil_name except: print 'root_airfoil_name is not defined in the inputs file' print 'Exiting!' sys.exit(1) else: airfoil_type = 'blended' else: airfoil_type = 'single' # Read airfoil data if airfoil_type == 'single': airfoil = np.loadtxt('./airfoils/'+airfoil_name+'.dat',skiprows=1,delimiter=',') # Create splines mach_data = airfoil[:,0] alpha_data = airfoil[:,1] cd_data = airfoil[:,2] cl_data = airfoil[:,3] cm_data = airfoil[:,4] # Determine Mach Range if min(mach_data) == max(mach_data): # Single Mach Number present, Create 1D splines airfoil_data_type = '1D' cd_spline = scipy.interpolate.splrep(alpha_data,cd_data) cl_spline = scipy.interpolate.splrep(alpha_data,cl_data) cm_spline = scipy.interpolate.splrep(alpha_data,cm_data) else: # Multiple Mach Numbers present, Create 2D splines airfoil_data_type = '2D' cd_spline = scipy.interpolate.bisplrep(mach_data,alpha_data,cd_data) cl_spline = scipy.interpolate.bisplrep(mach_data,alpha_data,cl_data) cm_spline = scipy.interpolate.bisplrep(mach_data,alpha_data,cm_data) else: # Tip airfoil = np.loadtxt('./airfoils/'+tip_airfoil_name+'.dat',skiprows=1,delimiter=',') # Create splines mach_data = airfoil[:,0] alpha_data = airfoil[:,1] cd_data = airfoil[:,2] cl_data = airfoil[:,3] cm_data = airfoil[:,4] # Determine Mach Range if min(mach_data) == max(mach_data): # Single Mach Number present, Create 1D splines tip_airfoil_data_type = '1D' tip_cd_spline = scipy.interpolate.splrep(alpha_data,cd_data) tip_cl_spline = scipy.interpolate.splrep(alpha_data,cl_data) tip_cm_spline = scipy.interpolate.splrep(alpha_data,cm_data) else: # Multiple Mach Numbers present, Create 2D splines tip_airfoil_data_type = '2D' tip_cd_spline = scipy.interpolate.bisplrep(mach_data,alpha_data,cd_data) tip_cl_spline = scipy.interpolate.bisplrep(mach_data,alpha_data,cl_data) tip_cm_spline = scipy.interpolate.bisplrep(mach_data,alpha_data,cm_data) # Root airfoil = np.loadtxt('./airfoils/'+root_airfoil_name+'.dat',skiprows=1,delimiter=',') # Create splines mach_data = airfoil[:,0] alpha_data = airfoil[:,1] cd_data = airfoil[:,2] cl_data = airfoil[:,3] cm_data = airfoil[:,4] # Determine Mach Range if min(mach_data) == max(mach_data): # Single Mach Number present, Create 1D splines root_airfoil_data_type = '1D' root_cd_spline = scipy.interpolate.splrep(alpha_data,cd_data) root_cl_spline = scipy.interpolate.splrep(alpha_data,cl_data) root_cm_spline = scipy.interpolate.splrep(alpha_data,cm_data) else: # Multiple Mach Numbers present, Create 2D splines root_airfoil_data_type = '2D' root_cd_spline = scipy.interpolate.bisplrep(mach_data,alpha_data,cd_data) root_cl_spline = scipy.interpolate.bisplrep(mach_data,alpha_data,cl_data) root_cm_spline = scipy.interpolate.bisplrep(mach_data,alpha_data,cm_data) # Initial Calculations tip_radius = diameter/2 area = pi*diameter*diameter/4 avg_chord = (root_chord + tip_chord)/2 sigma=2*avg_chord/2/pi/tip_radius # solidity # Blade Element Calculation r_inc = (tip_radius-root_radius)/(num_elements-1) theta_inc = (tip_theta-root_theta)/(num_elements-1) chord_inc = (tip_chord-root_chord)/(num_elements-1) # Initialize lists radius = [] theta = [] theta_rad = [] alpha_rad = [] chord = [] thrust = [] drag =[] torque = [] # Initialize total_output file total_output = open('./output.txt','w') # Print Data Header total_output.write(' RPM\tT(N)\tP(kW)\tM(N-m)\\(kg-cm)\t\tT(lbf)\tP(Hp)\tM(ft-lb)\t\tFM\tM_tip\tv_induced\n') # Initialize total_output file radial_output = open('./radial_output.txt','w') # Print Data Header radial_output.write('i\\RPM\t') for i in range(num_elements): radial_output.write(str(i)+'\t') radial_output.write('\n') # Populate radii and theta lists for i in range(num_elements): radius.append(root_radius+i*r_inc) chord.append(root_chord+chord_inc) theta.append(root_theta+i*theta_inc) theta_rad.append(theta[i]/180*pi) alpha_rad.append(0) # Specified Theta #theta = [18.00, 17.34, 16.68, 16.03, 15.37, 14.71, 14.05, 13.39, 12.74, 12.08, 11.42, 10.76, 10.10, 9.44, 8.79, 8.13, 7.47, 6.82, 6.16, 5.50] #for i in range(num_elements): # theta_rad[i] = (theta[i]/180*pi) #print theta for RPM in RPMs: # Initial Calcs at RPM n = RPM/60 # RPS omega = n*2*pi # angular velocity V_tip = omega*tip_radius # tip velocity # Initialize/Clear Lists thrust = [] drag = [] moment = [] torque = [] for i in range(num_elements): # Guess at initial values of inflow and swirl factor # Note: swirl currently isn't used v_inflow = 10 #v_swirl = 0.1 # Iterate at Each Blade Element iter = 0 finished = False while( finished == False): v_axial = v_inflow # axial velocity v_radial = omega*radius[i] # disk plane velocity #v_radial = omega*radius[i] - v_swirl # disk plane velocity v_mag = pow((v_axial*v_axial+v_radial*v_radial),0.5) # local velocity at blade (Resultant of Induced & Radial) mach = v_mag/a phi_rad = math.atan2(v_axial,v_radial) # flow angle (radians) alpha_rad[i] = theta_rad[i]- phi_rad # blade angle of attack #cl,cd = airfoil_coef(alpha_rad[i]) alpha = alpha_rad[i]*180/pi alpha = min(alpha,12) # Find section coefficients if airfoil_type == 'single': if airfoil_data_type == '1D': cd = scipy.interpolate.splev(alpha,cd_spline) cl = scipy.interpolate.splev(alpha,cl_spline) cm = scipy.interpolate.splev(alpha,cm_spline) elif airfoil_data_type == '2D': cd = scipy.interpolate.bisplev(mach,alpha,cd_spline) cl = scipy.interpolate.bisplev(mach,alpha,cl_spline) cm = scipy.interpolate.bisplev(mach,alpha,cm_spline) else: # Tip if tip_airfoil_data_type == '1D': tip_cd = scipy.interpolate.splev(alpha,tip_cd_spline) tip_cl = scipy.interpolate.splev(alpha,tip_cl_spline) tip_cm = scipy.interpolate.splev(alpha,tip_cm_spline) elif tip_airfoil_data_type == '2D': tip_cd = scipy.interpolate.bisplev(mach,alpha,tip_cd_spline) tip_cl = scipy.interpolate.bisplev(mach,alpha,tip_cl_spline) tip_cm = scipy.interpolate.bisplev(mach,alpha,tip_cm_spline) # Root if root_airfoil_data_type == '1D': root_cd = scipy.interpolate.splev(alpha,root_cd_spline) root_cl = scipy.interpolate.splev(alpha,root_cl_spline) root_cm = scipy.interpolate.splev(alpha,root_cm_spline) elif root_airfoil_data_type == '2D': root_cd = scipy.interpolate.bisplev(mach,alpha,root_cd_spline) root_cl = scipy.interpolate.bisplev(mach,alpha,root_cl_spline) root_cm = scipy.interpolate.bisplev(mach,alpha,root_cm_spline) # Interpolate cd, cl, cm tip_portion = float(i)/(num_elements-1) root_portion = float(num_elements-1-i)/(num_elements-1) cd = tip_portion*tip_cd + root_portion*root_cd cl = tip_portion*tip_cl + root_portion*root_cl cm = tip_portion*tip_cm + root_portion*root_cm # Appply drag factor cd = cd*drag_factor q = 0.5*rho*pow(v_mag,2) # local dynamic pressure DtDr = q*blades*chord[i]*(cl*math.cos(phi_rad)-cd*math.sin(phi_rad)) # thrust grading DdDr = q*blades*chord[i]*(cd*math.cos(phi_rad)+cl*math.sin(phi_rad)) # drag grading DmDr = q*blades*chord[i]*cm # moment grading DqDr = q*blades*chord[i]*radius[i]*(cd*math.cos(phi_rad)+cl*math.sin(phi_rad)) # torque grading # momentum check on inflow and swirl factors v_inflow_new = DtDr/(4*pi*radius[i]*rho*v_axial) #v_swirl_new = DqDr/(4*pi*pow(radius[i],3)*rho*v_axial*omega) # increment iteration count iter += 1 # check for convergence if ( math.fabs(v_inflow_new-v_inflow)< 0.001): finished = True # check to see if iterations are stuck elif(iter>maximum_iterations): finished=True print 'RPM:',RPM,'element:',i,'exceed maximum number of iterations (',maximum_iterations,')' # Updates Values v_inflow = v_inflow + relaxation_factor*(v_inflow_new-v_inflow) #v_swirl = v_inflow + 0.5*(v_swirl_new-v_swirl) phi = phi_rad*180/pi alpha = alpha_rad[i]*180/pi thrust.append(DtDr*r_inc) drag.append(DdDr*r_inc) moment.append(DmDr*r_inc) torque.append(DqDr*r_inc) #print RPM,i,v_inflow # Convert radians to degrees radial_output.write('{:d}\t'.format(RPM)) for i in range(num_elements): theta[i] = theta[i]*180/pi alpha_rad[i] = alpha_rad[i]*180/pi radial_output.write('{:5.3f}\t'.format(alpha_rad[i])) radial_output.write('\n') # Totals T = sum(thrust) # total thrust (N) P = sum(torque)*omega/1000 # total power (kW) M = sum(moment) # total moment (N-m) M_kg = M*10.1971621298 # total moment (kg-cm) # Ideals v_ideal = pow((T/(2*rho*pi*pow(tip_radius,2))),0.5) # Ideal Induced Velocity (m/s) P_ideal = T*v_ideal/1000 # Ideal Power (kW) # Compute Coefficients ct = T/(rho*n*n*pow(diameter,4)) cq = sum(torque)/(rho*n*n*pow(diameter,5)) # Adjust for Tip Loss using Empirical Equations B = 1 - pow(2*ct,2)/2 P = P_ideal/B + (P - P_ideal) T_imp = T*0.224808943 # N to lbf P_imp = P*0.00134102209*1000 # kW to Hp M_imp = M*0.737562149 # N-m to ft-lbf FM = P_ideal/P M_tip = v_mag/a total_output.write('{:5d}\t{:5.2f}\t{:5.2f}\t{:6.3f}\\{:6.3f}\t\t{:5.2f}\t{:5.2f}\t{:6.3f}\t\t{:5.3f}\t{:5.3f}\t{:5.3f}\n'.format(RPM,T,P,M,M_kg,T_imp,P_imp,M_imp,FM,M_tip,v_ideal)) # Close total_output total_output.close() radial_output.close() -

Rotor Repository

07/22/2015 at 05:08 • 0 commentsA new rotor design github repository is being created to store the rotor information separate from the Goliath design repository. This new repository will contain the design files for the previous rotor design (alpha) and the new rotor design (beta). The repository will also contain the python program developed to predict the rotor thrust.

-

Documentation

10/23/2014 at 11:15 • 0 commentsI'm starting a separate project for the propellers that I've been building for #Goliath - A Gas Powered Quadcopter. As Goliath has progressed, the documentation of all the elements is becoming a bit unwieldy and the rotors are a project on there own. The plan is to more thoroughly document the rotors here than they have on Goliath's project log and also describe the project in more generic terms for anyone to apply towards their own applications.

Inexpensive Composite Propellers/Rotors

How to make inexpensive propellers using mostly hardware store materials and a CNC router

Peter McCloud

Peter McCloud