Finished a new impeller motor.

Added optical feedback. Used an old mechanical mouse wheel with every other tooth removed, and machined a new shaft coupler.

I must have damaged the bushings along the way. It no longer spins freely. I wasn't liking how heavy it was either. I trashed it.

Decided to go a different route.

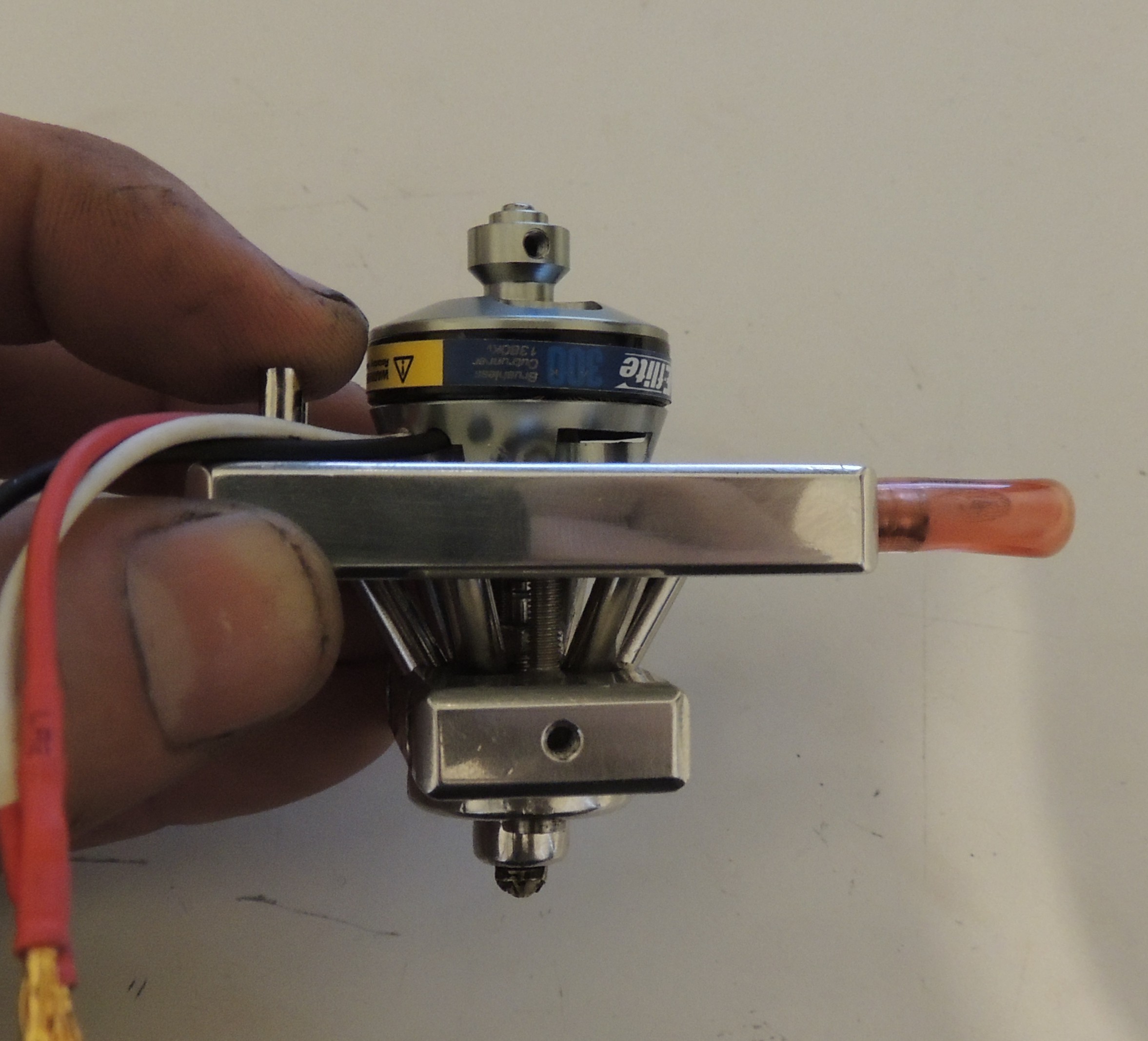

Modified the motor mounts and put a quad copter outrunner on it. It is thermally coupled to my water cooling plate so I should be able to run it pretty hard with no airflow. Problem is, without any give in the mounting of the motor now, alignment of the motor and impeller drive is critical. It's very close, but needs some tweaking.

Re-machined the hot end to cold end screws to now terminate into the cold end plate. Previously they went directly into the motor.

Figured out the timing I need for driving the ESC with my Beaglebone PWM.

Basically, run my PWM at 100Hz (which it already is) , and then setting 10%-20% duty cycle will generate the 1ms to 2ms pulses the ESC is looking for to give 0-100% throttle. For my particular ESC, setting the throttle range will be accomplished by powering it up at 20%, then reducing to 10% within 2 seconds. The rest of the ESC settings look good for my 12v source. I'm hoping it doesn't 'lag'...

Somewhere along the line I also managed to bend my stainless impeller shaft. Need to machine a new one.

Daren Schwenke

Daren Schwenke

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.