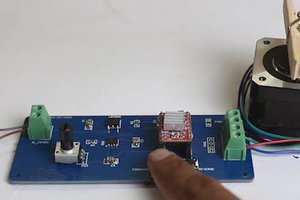

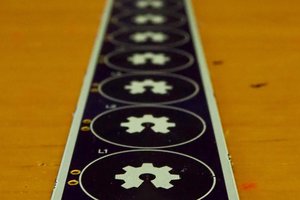

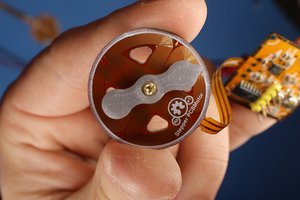

My PCB-Motor is made from a 6-pole stator printed on a 4-layer PCB and a 4-pole 3d printed rotor. Its has an outer diameter of 16mm and is rated at 1 watt.

I had this idea when I was trying to design a small compact drone. The PCB motor is much cheaper than other micro brushless motors and also easier to assemble. My goal is to make the rotor part of the BOM and mounted just like any other component on a PCB.

VIDEO

HACKADAY SUPERCON DEMO

Carl Bugeja

Carl Bugeja

Mrinnovative

Mrinnovative

I am thinking about scaling this up in size and stacking motors and rotors to build a lighter and more efficient hub motor for one person electric vehicles.