I love designing electronics that fit in very tiny space. My 4-layer brushless PCB Motor is currently 16mm in diameter. So how can I make it smaller?

This 16mm design is already pushing the limits by having 4mils (0.1mm) track width and clearance. Using thinner pcb traces is possible, but would make its price (for prototyping) explode. My intent is to make this open source motor accessible to others, so it doesn't makes much sens to go in this direction. So I'm sticking to 4/4mil traces.

My motor has around 40 turns, so going much lower than that would make the coils too inefficient and the pcb would heat up way to much. Based on a my pcb coils tests the minimum number of turns for 4mil should be 40 turns and for 5mil it should be 60 turns, not to exceed 70°C with a constant (100% duty cycle) supply.

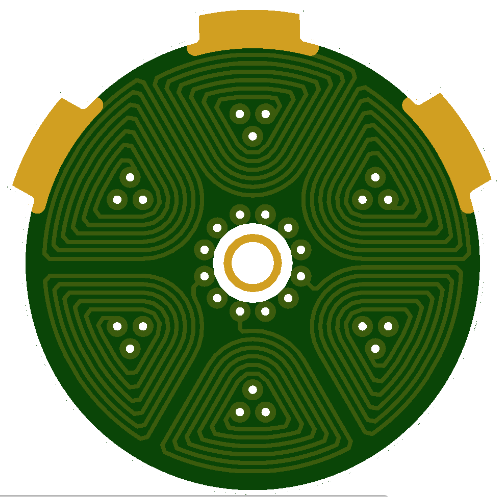

The only remaining option to try and make it smaller, is to increase the number of layers to decrease the number of turns per layer. The current design has 10 turns per layer, so for this tiny 6-layer motor I decided to go for 6 turns per layer, having a total of 36 turns. Setting a tight clearance of 4mil, the total diameter of the motor end up being 11mm.

The extra two layer, increased the number of vias in the middle of each coil to three. This naturally formed the spiral to have a triangular shape which use the area of the magnetic field more efficiently.

Another natural advantage of using a 6-layer pcb, is that the thickness between each layer is much smaller which increases the magnetic field strength.

For this design I had to make some changes on the rotor, because I couldn't find a bearing small enough to fit at the center of the pcb (smallest bearing available is 2mm). So what i decided to do is extended a stationary-shaft from the pcb, and connect the bearing on the rotor. I'm still designing the 3d-printed part, so I will post more info on that soon.

I have just ordered this 6-layer pcb motor from JLCPCB which were kind enough to sponsor this design.

We'll see how it goes!

Carl Bugeja

Carl Bugeja

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Hi, I have a question, how do you route the coils on your pcb? And wich PCB design software do you use?

Very interesting BTW!

Are you sure? yes | no

Hi men, can I kindly ask you to send kicad file of this pcb 6-layer motor on hibissscus@gmail.com I have my pcbs on JLCPCB, and it would be nice to reuse my DHL delivery and print also your nice PCB to check out, thank you in advance for such a great job and please keep posting.

Are you sure? yes | no

interesting!

one possible elaboration is that now that the vias are offset symmetrically and the board is a little thicker, you could drill out the center (leaving 2/3 of each intact), and insert a ferrite bead to try to increase field strength.

Are you sure? yes | no