- It's quiet and fast.

- It will take 10-40 hours of your life.

- Your toddler or his friends drawing on it won't ruin your day.

This revision has worked flawlessly, with no further adjustment and with daily use, for almost 2 years now.

EDIT: 3 houses and almost 10 years after this one was first created... still going strong. I bent the threaded rod a bit in one of the moves, but it doesn't affect the operation so I left it. I guess I should probably upload that schematic sometime in the next 10 years to stay on schedule.

Theory of Operation

The wiper motor is a worm gear drive and a pretty low ratio. You can direct drive the fence post at a slow even pace, no problem.

The motor turns threaded rod attached to the chain link fence post onto which the light block fabric is spooled. Support at both ends with roller blade bearings (which happen to perfectly fit 5/16in threaded rod)

The 1/2 in conduit provides a tiny bit of horizontal tension and weight across the bottom edge. The screen is tensioned vertically with this weight. You can adjust how the tension behaves by adding additional weight (filling it).

As the screen moves up, a coupler nut with an attached post moves slowly one direction. The post slides along the corner brace which stops the coupler nut from spinning around the threaded rod.

A relay, triggered from the projector 'remote power', is wired as a reversing switch. Power applied to the relay triggers the screen to descend. The motor is powered from a supply independent from the projector.

The roller switches are positioned at either end of the desired range of motion of the coupler nut/post. The post impacting either switch, simultaneously removes the motor power, and shorts the motor windings providing simple, effective electronic braking.

Mounting the roller switches by the rear screw only allows for easy adjustment in very fine increments of either stopping point. I can tune mine to within 1/8th in of travel at either stop.

The screen itself was made as three sections of 'light block' fabric, which were seamed horizontally with a clothes iron and some iron-on webbing (that was pretty hard to get perfect actually as you can't stretch or push the material or you'll get ripples in your finished screen). The outer two sections provided the top/bottom border and were painted with black camo paint. (test if your target paint tends to rub off first!) This lets you use the 'normal' width light block and still be able to make up to a 9ft - 16x9 aspect ratio screen with no seams.

Daren Schwenke

Daren Schwenke

Vipin M

Vipin M

Dominic

Dominic

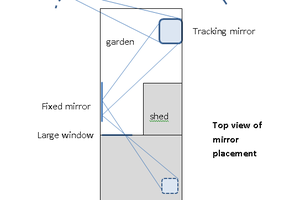

Roddy "Rags" Read

Roddy "Rags" Read