Purpose

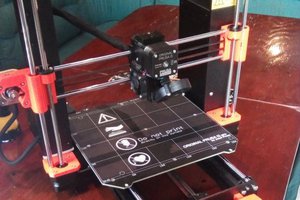

The original purpose of this project was to use the biomat as a test bed for various types of 3D printing. That didn't happen on the timeline I had originally intended. The new, rebooted, more vigorous purpose for converting the biomat is to simply finish the project. Once the core functionality is there I will move to more interesting things.

Current State: Non-functional mess.

The biggest issue right now is the hot-end. The thermistor keeps falling out and the hotend keeps melting down. After that comes the non-existent hot-plate. I don't know what material I will use yet, but theres a good bet I'll use an aluminum base plate and then a thinner sheet of some sort of plastic (sort of like what 3D Systems does on their FDM machines).

To Do

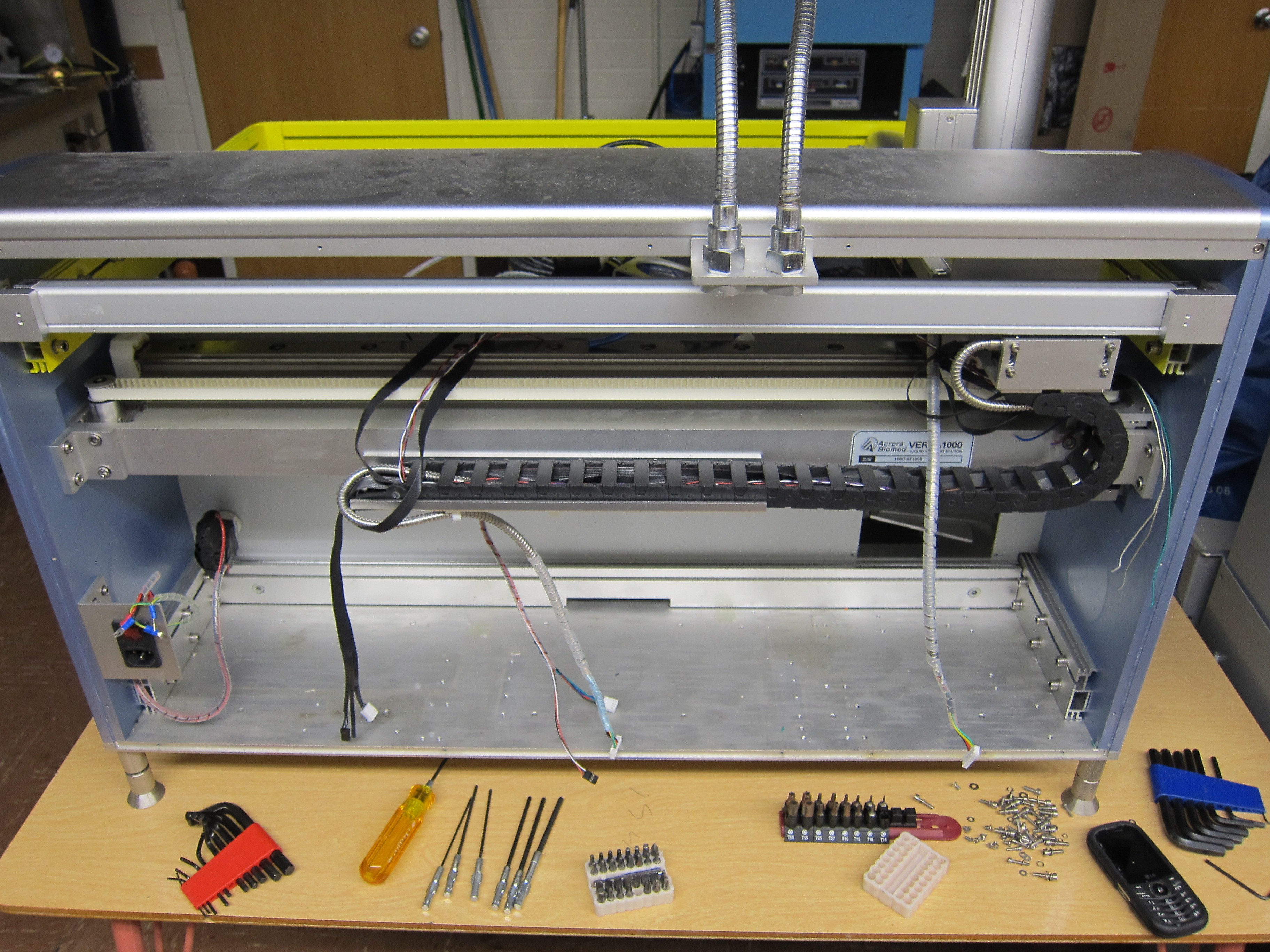

- G̶u̶t̶ ̶i̶n̶t̶e̶r̶i̶o̶r̶, measure, model, and test fit everything that has to go inside.

- Measure out and build wire-harness for bare essentials (steppers, endstops, e-stop, hotend, hot-plate).

- Research and build hot-plate. (maybe self leveling?)

- ???

- Profit.

Albert Latham

Albert Latham

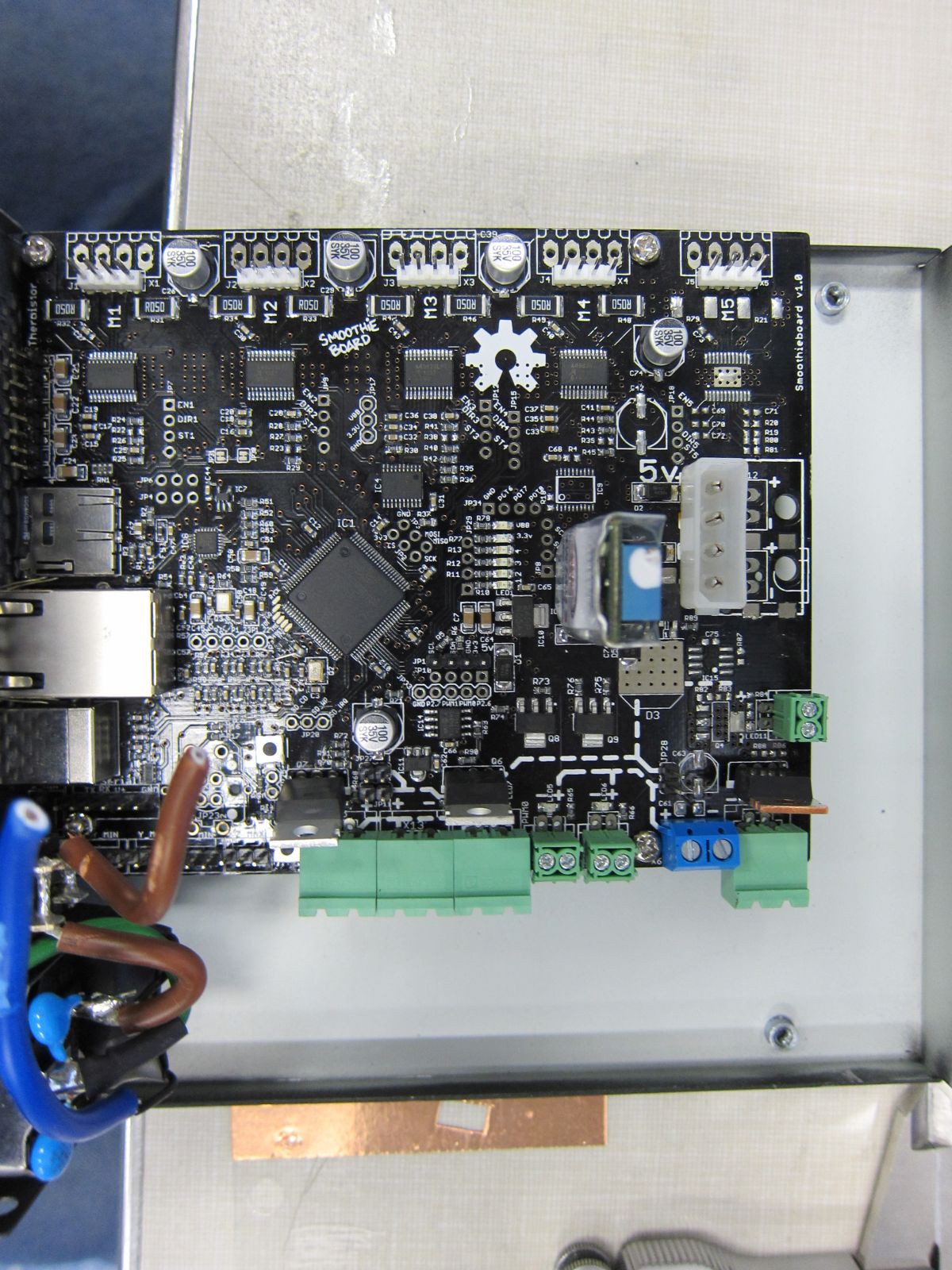

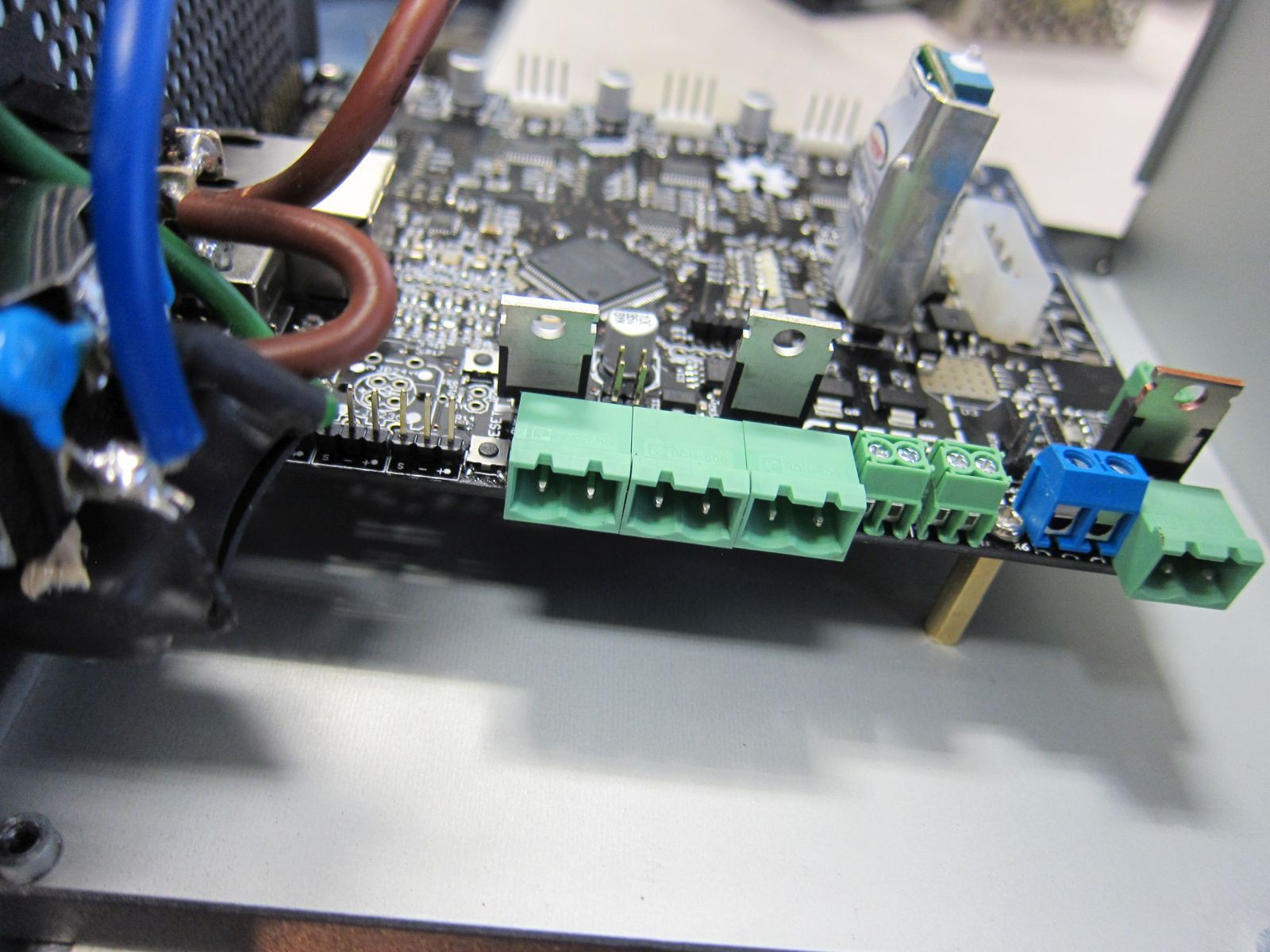

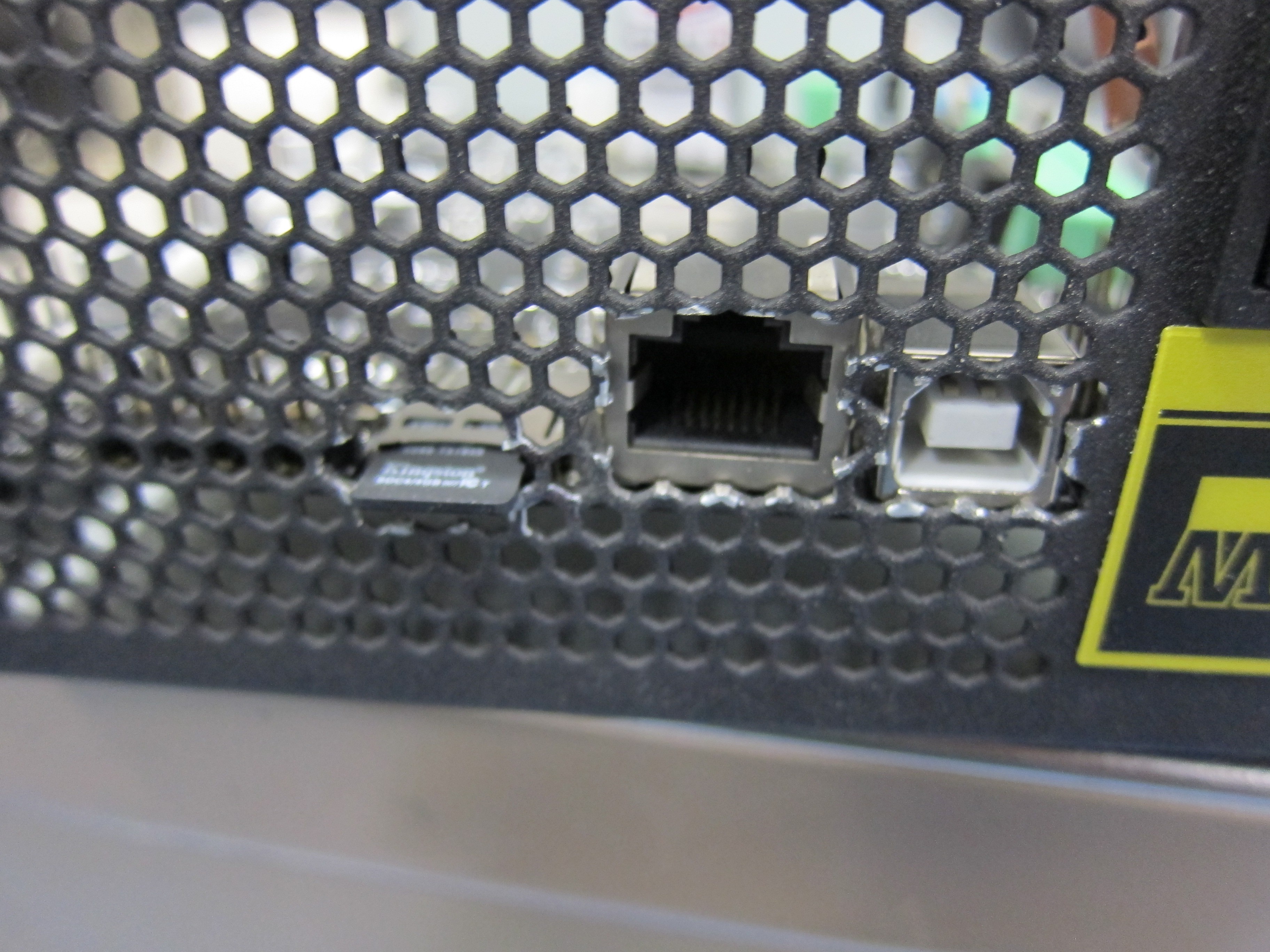

Having successfully installed the Smoothie I punched holes for the SD card, ethernet port, and the USB port. I did some other stuff, too, but I didn't take any pictures.

Having successfully installed the Smoothie I punched holes for the SD card, ethernet port, and the USB port. I did some other stuff, too, but I didn't take any pictures.

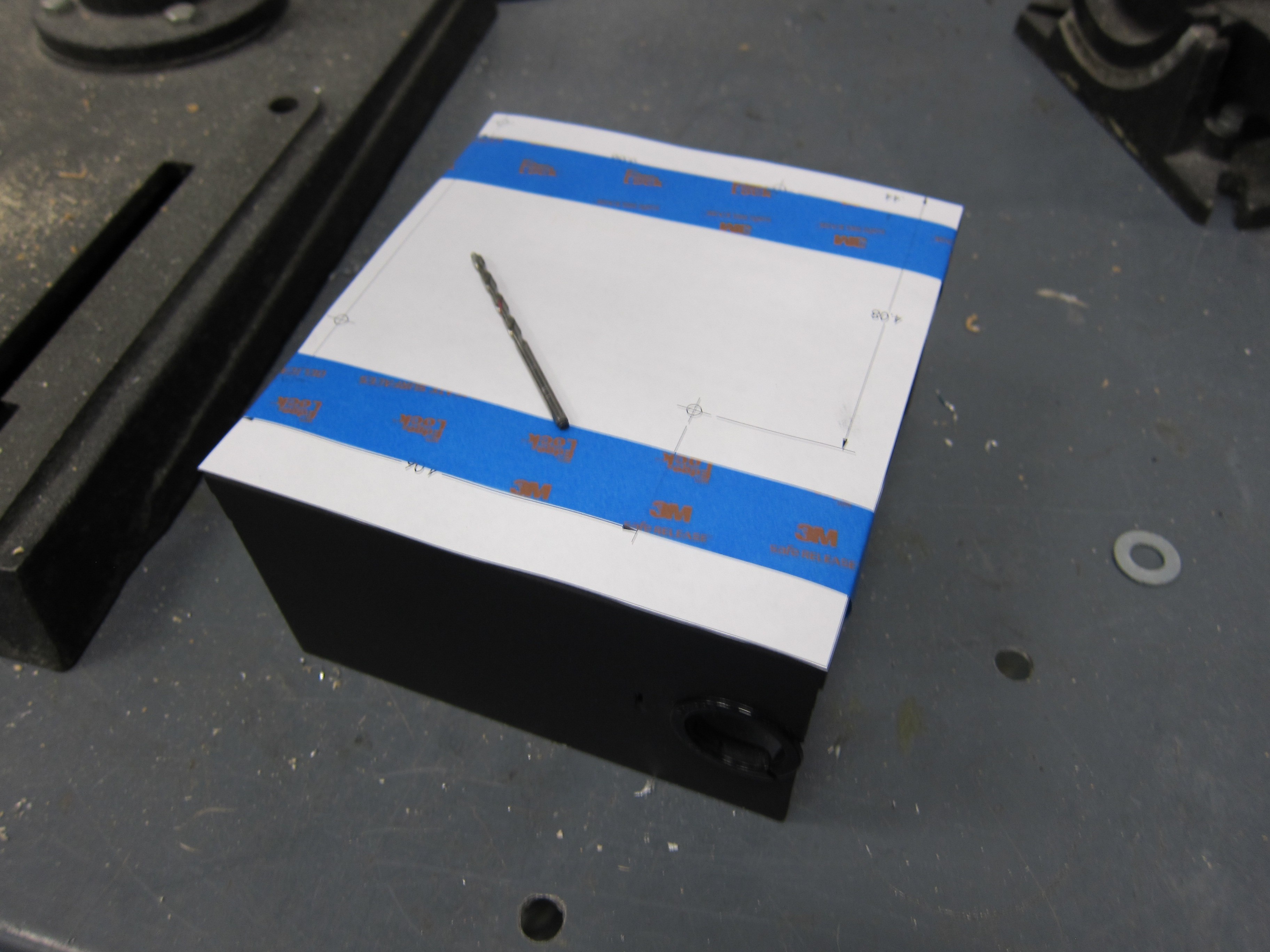

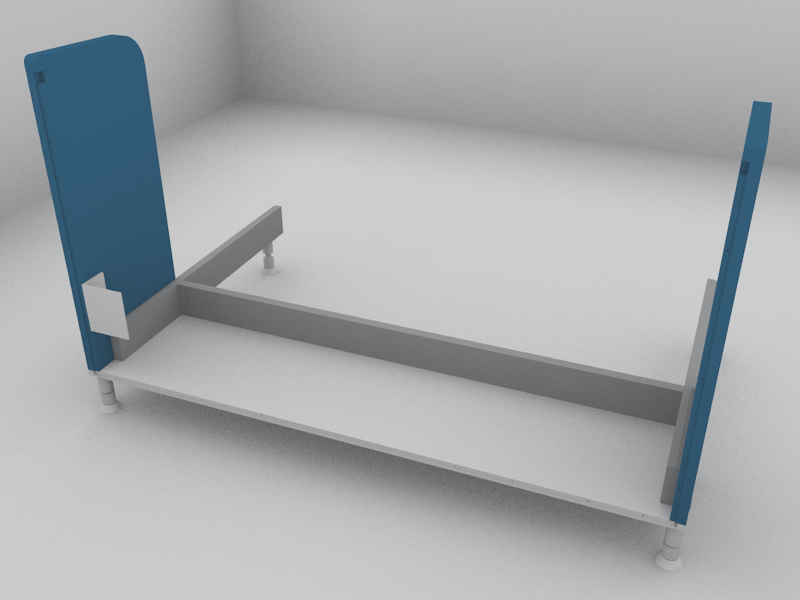

Why yes, that is Blender's ambient occlusion render setting yous see. I could have modeled this in solidworks, but that would have been no fun at all. I need to model all the components that go inside and get to test fitting them.

Why yes, that is Blender's ambient occlusion render setting yous see. I could have modeled this in solidworks, but that would have been no fun at all. I need to model all the components that go inside and get to test fitting them.

balintechnologies

balintechnologies

The Lab Guy

The Lab Guy

Patrick

Patrick

T. B. Trzepacz

T. B. Trzepacz