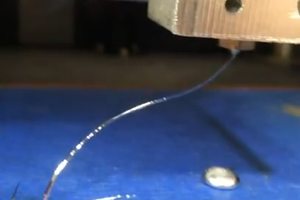

My first attempt used flexible TPU filament to replicate the rubber tubing in place. The proved to be a failure, the TPU does not do a good job of holding pressure. The next try used PLA. The first picture shows what the first version looked like post vehicle test. PLA does print well and quickly, and holds pressure well. It does not hold up to engine bay ambient heat well though, and deformed and popped off. I turned to PETG, and revamped the modeling. Pic 2 shows version two test printed in PLA.

I had some PETG problems including extrusion issues because I did not have the all metal hotend mod installed. I also had a weird sidewall failure seen in pic 3. Pic. 4 shows the heat deforming that occurred with hose clamp pressure applied in the bay. Pic. 5 and 6 show the rubber coating an aluminum tape that I used to seal any micro holes in the sidewall, and well as provide insulation against further heat damage. Pic. 6 is like the version currently been road tested in the car. The following pics, show my pressure testing setup that I used to test for leaks and viability of use. It is comprised of PVC end caps with a Schraeder valve mounted in one end that allows the closed system to be pressurized by a bike pump. The pressure can then by taken by a gauge over time and measure how long pressure is held and at what psi.

The version in my car is printed at slow speeds at 255c with a 65c bed temp, and .04 layer height for 72 hours. This has lasted several trips the longest any tube has lasted so far.

| Test Date | Drive Duration (min) | Max Speed (mph) | Average Speed (mph) | Max Boost (psi) | Average Boost (psi) | Ambient Temperature (deg.F) | Engine Temperature Average (deg.F) | Engine Temperature Max (deg.F) | Drive Distance (mi.) | Oil Temp max (deg. F) | Max Rpm |

| 12/19/2017 | 35 | 80 | 40 | 7.5 | 5 | 50 | 165 | 210 | 25 | 195 | 5000 |

| 35 | 80 | 40 | 7.5 | 5 | 50 | 165 | 210 | 25 | 195 | 5000 | |

| 12/20/2017 | 21 | 50 | 30 | 7 | 5 | 62 | 165 | 210 | 15 | 200 | 4500 |

| 29 | 50 | 25 | 7 | 5 | 62 | 165 | 210 | 15 | 200 | 4500 | |

| 12/29/2017 | 10 | 50 | 14 | 5 | 4 | 61 | 163 | 168 | 5 | 200 | 3000 |

| 1/24/2018 | 26 | 75 | 26 | 6 | 5 | 50 | 160 | 198 | 19 | 200 | 4000 |

| 32 | 90 | 33 | 8 | 5 | 50 | 160 | 200 | 17 | 188 | 5500 |

The table shows several tests with their dates. I have tested in a wide range of conditions, including the last run where I raced a Dodge Dart, and won. At this time, the tube appears to be a complete success. It has lasted several runs with no problems, I have seen no boost leaks when I compare data to stock setup.

Mitja Breznik

Mitja Breznik

Michael Perrone

Michael Perrone

PointyOintment

PointyOintment

The radiator hose sounds like a good idea, I will look into it as my rubber hoses are all 28 years old, and beginning to show it and there are too many too big to print them all.