As every enthusiast DIYer working with power tools knows "buy cheap, buy twice" or cry twice. But not this time !

With cheap tools the Quality is rarely there, which is ok for me 'caus they are also very affordable. The annoying thing is the after sales service...

My thoughts on the brand :

Parkside tools are available at Lidl supermarket in Europe and on their website. I realy like these tools because they are very affordable and quite robust. They take the beating ! I collected some Parkside tools over the years and I was impressed almost every time over the robustness.

Motivation :

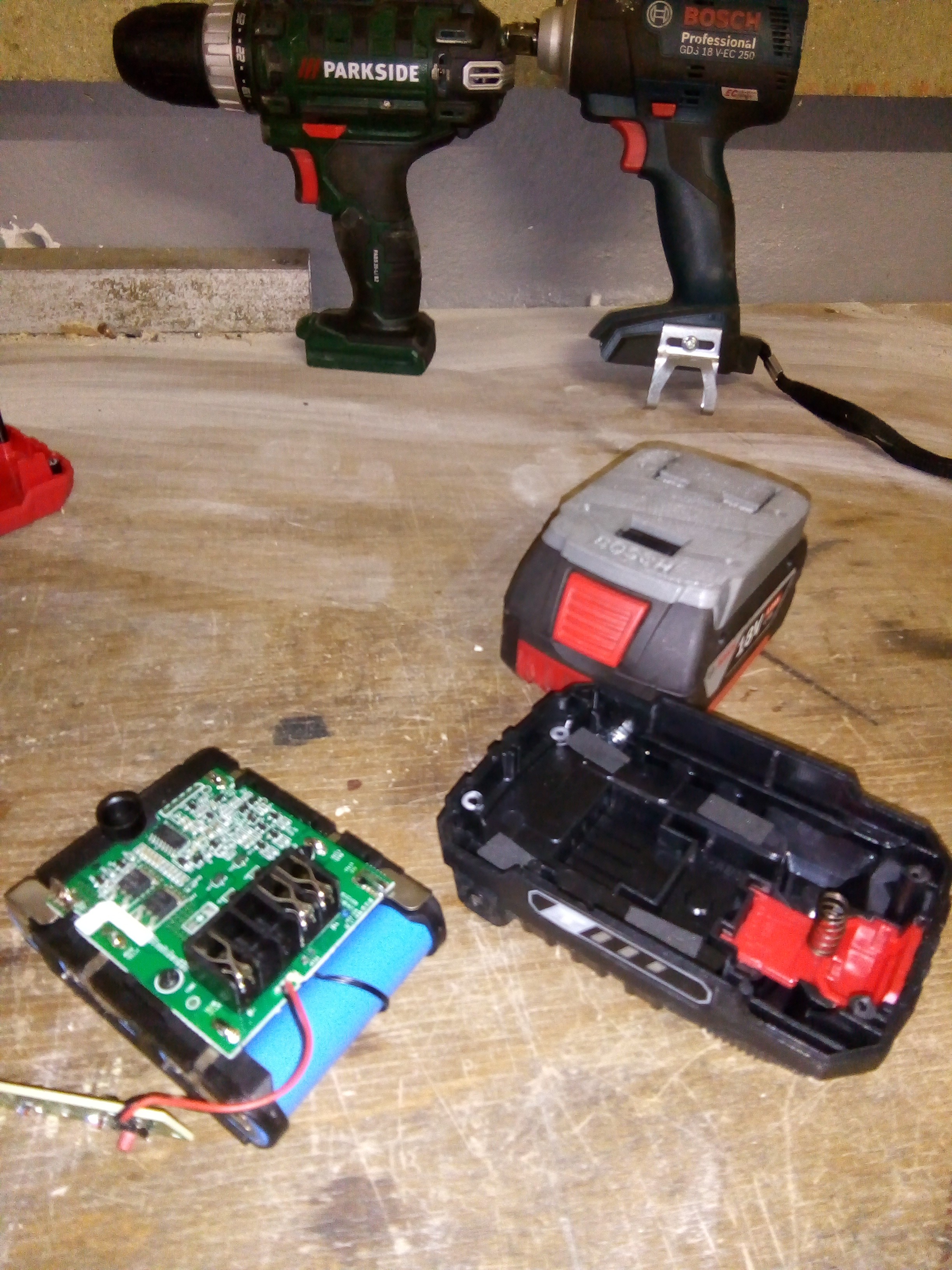

The drill cost me 49€ incl. charger and a 18V 2Ah battery. I had it for almost 2 years. The battery ran really weak so I looked up to buy a new one but after 2 years they launched a new line of cordless tools, and of course they also changed the battery. This means you can't buy a new one, not even those Ebay knockoffs.

I give it to them, they chosed a better battery design this time (now the socket resembles to what the other brands are doing).

Theory :

Because I also use Bosch Pro. 18v tools I could make an adapter.

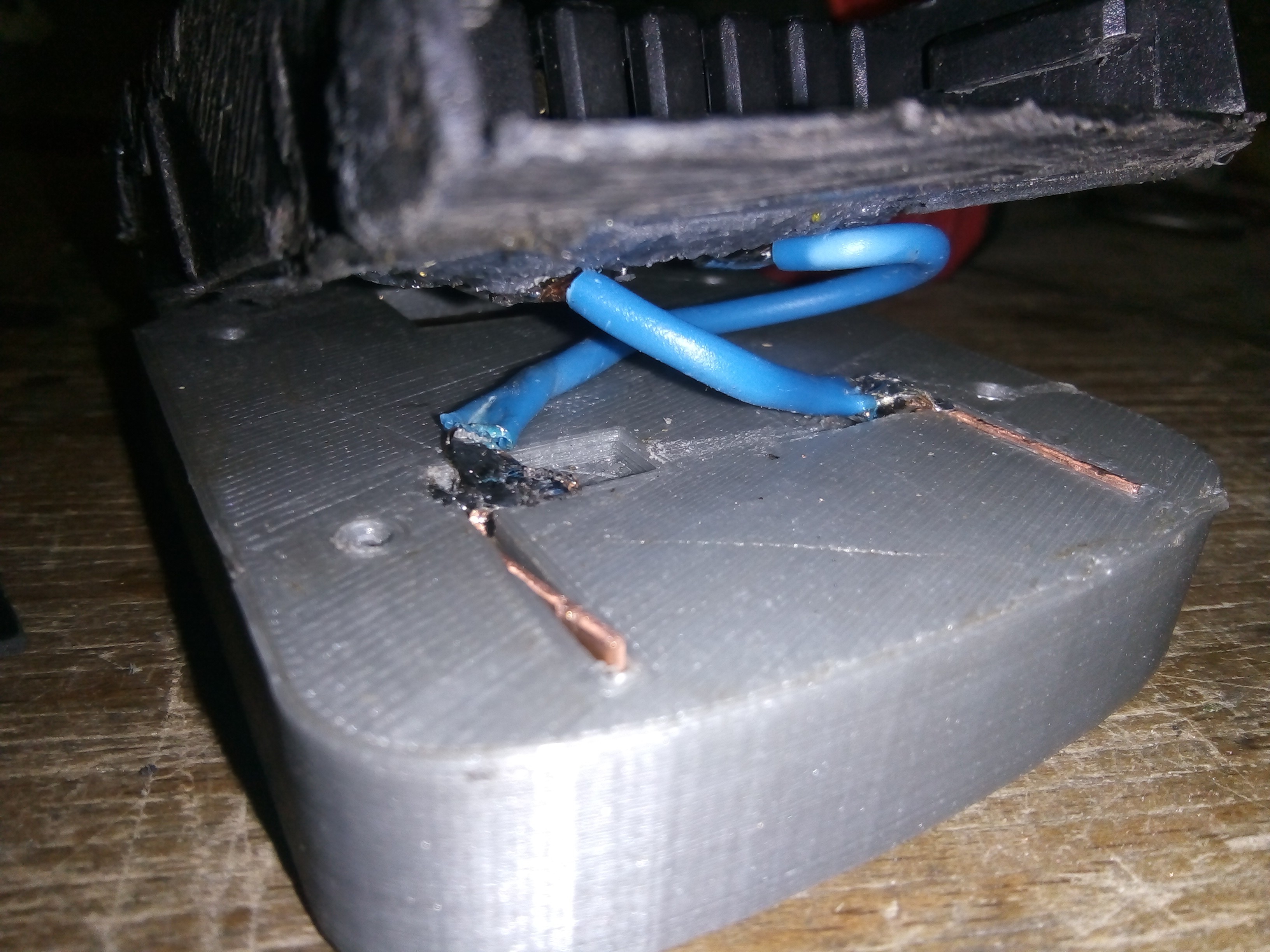

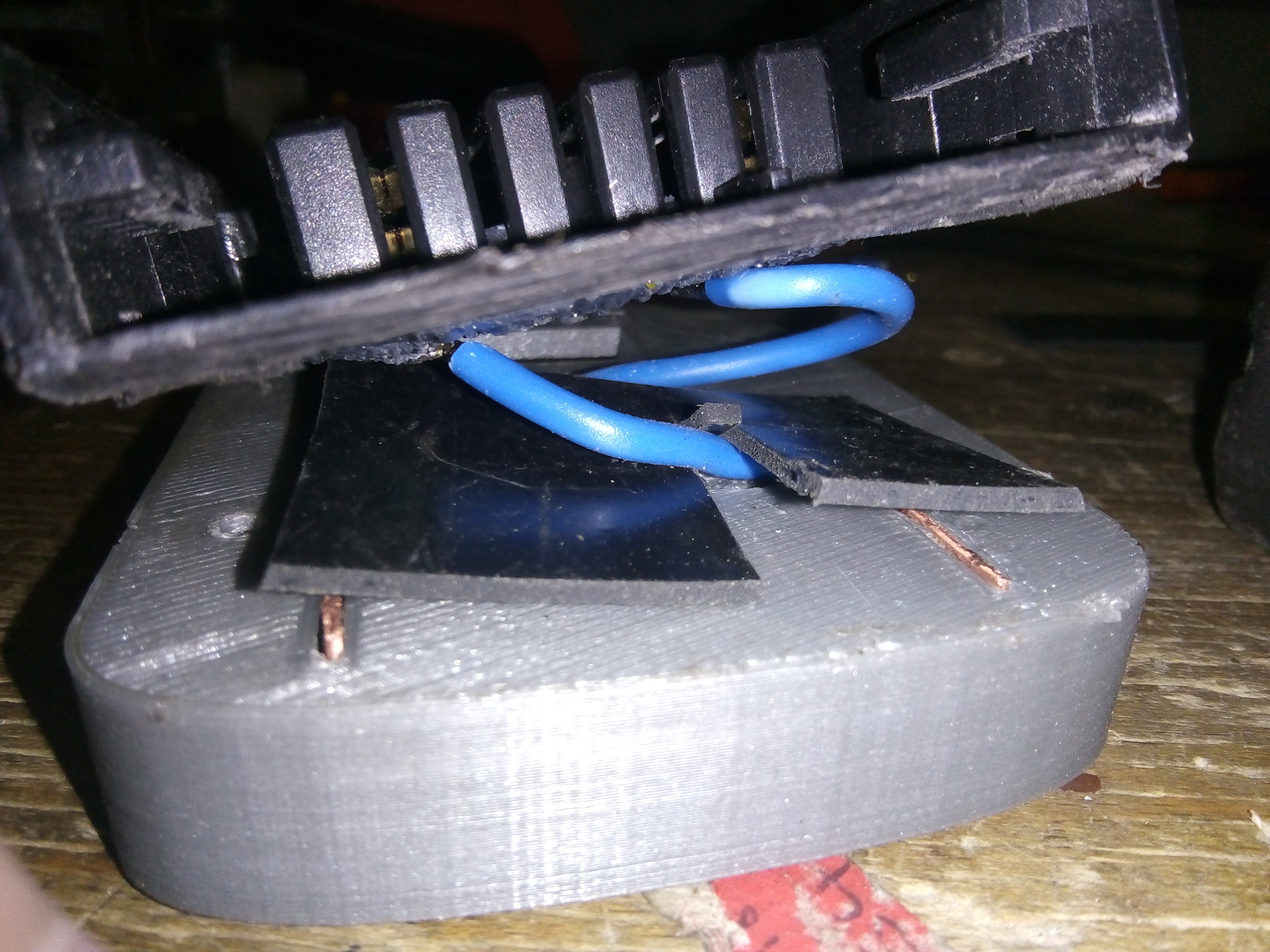

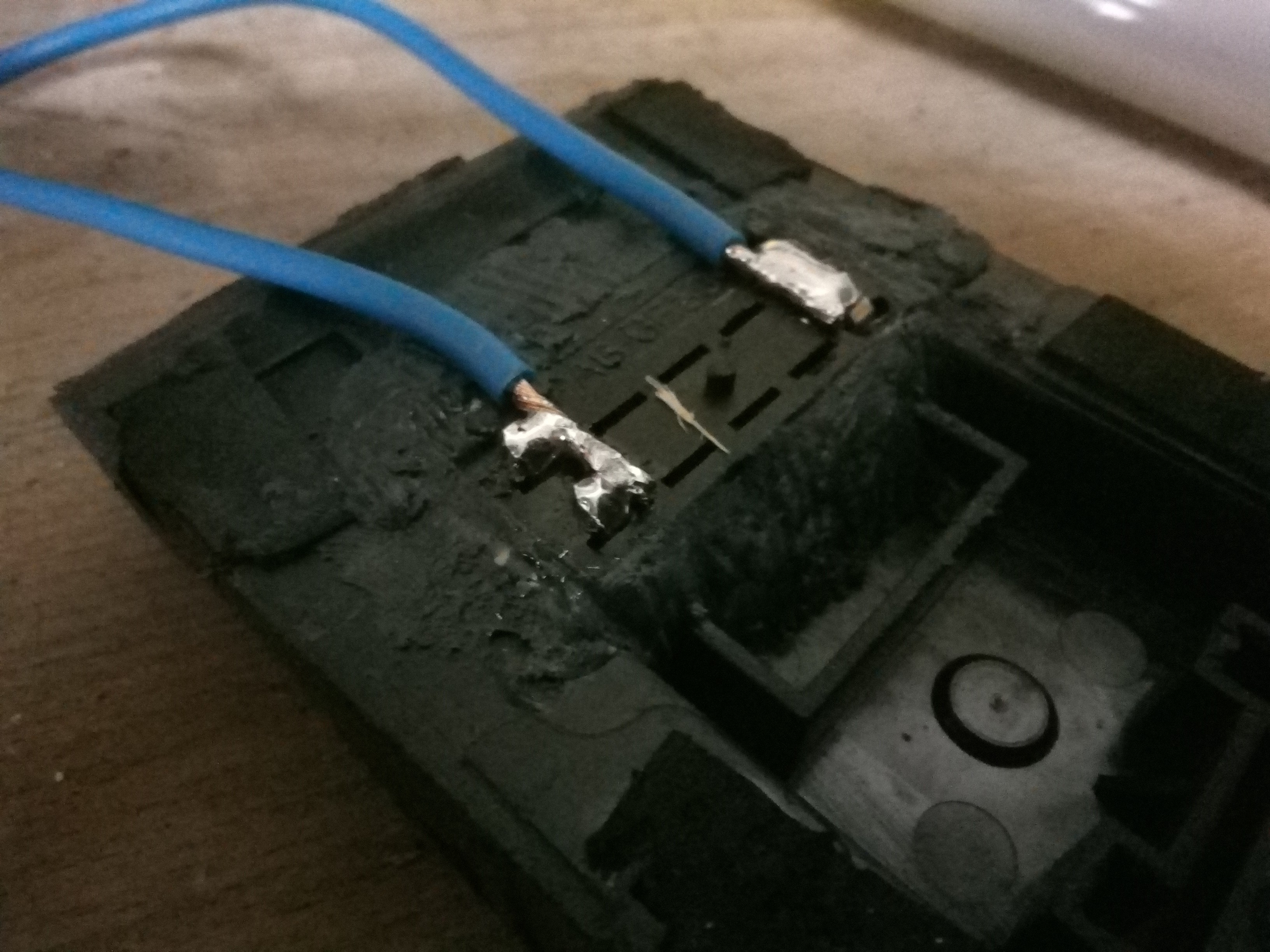

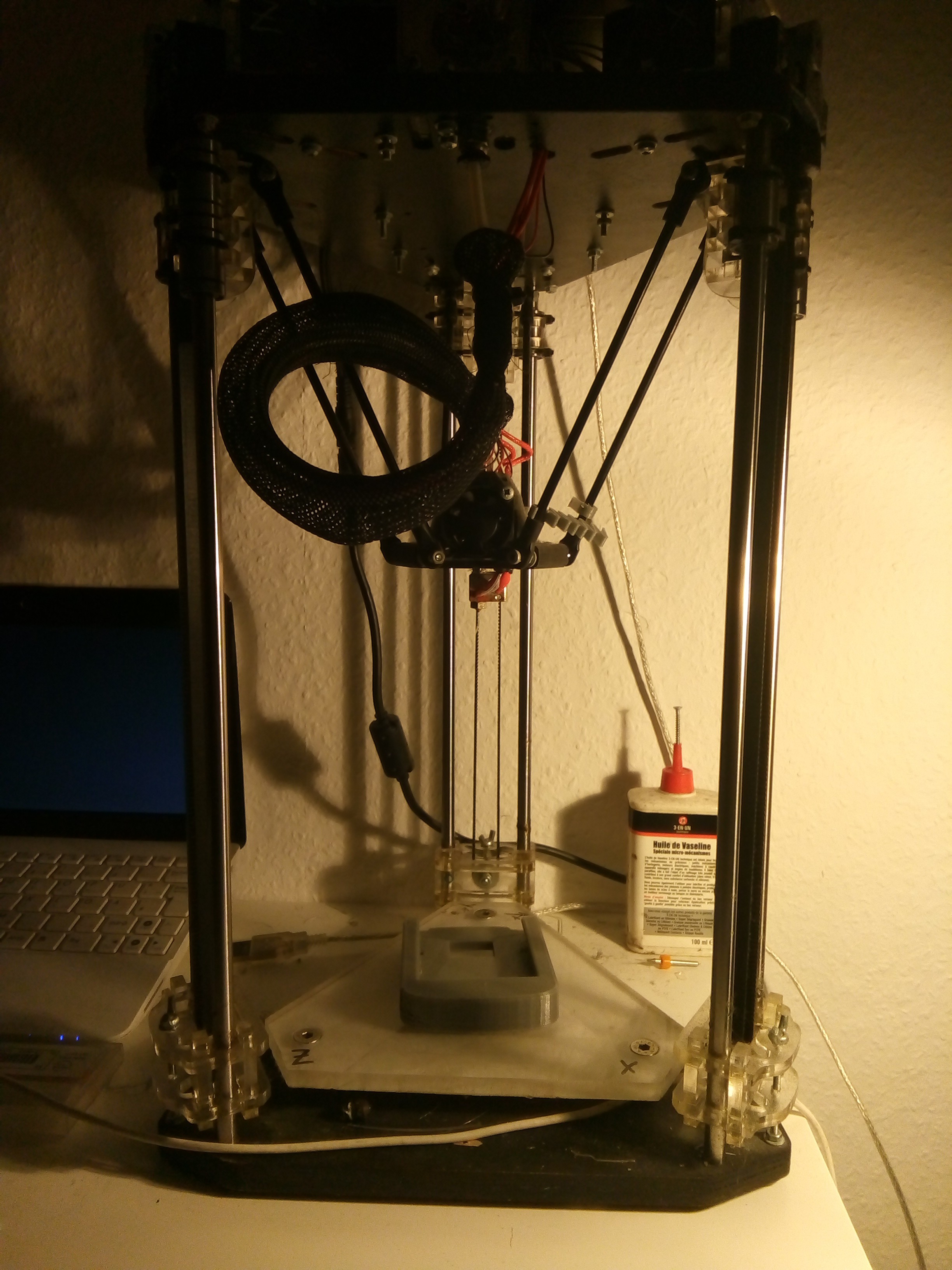

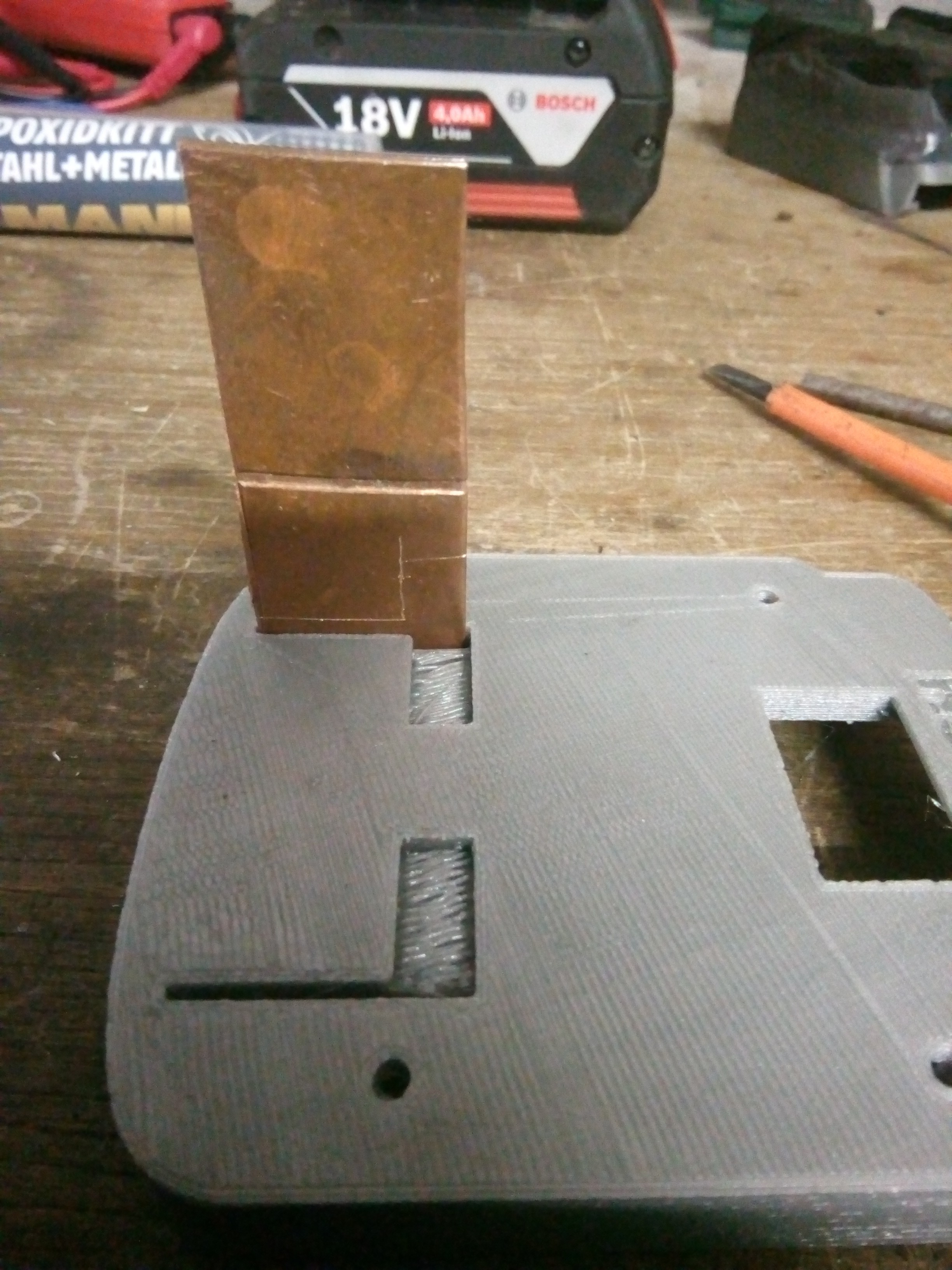

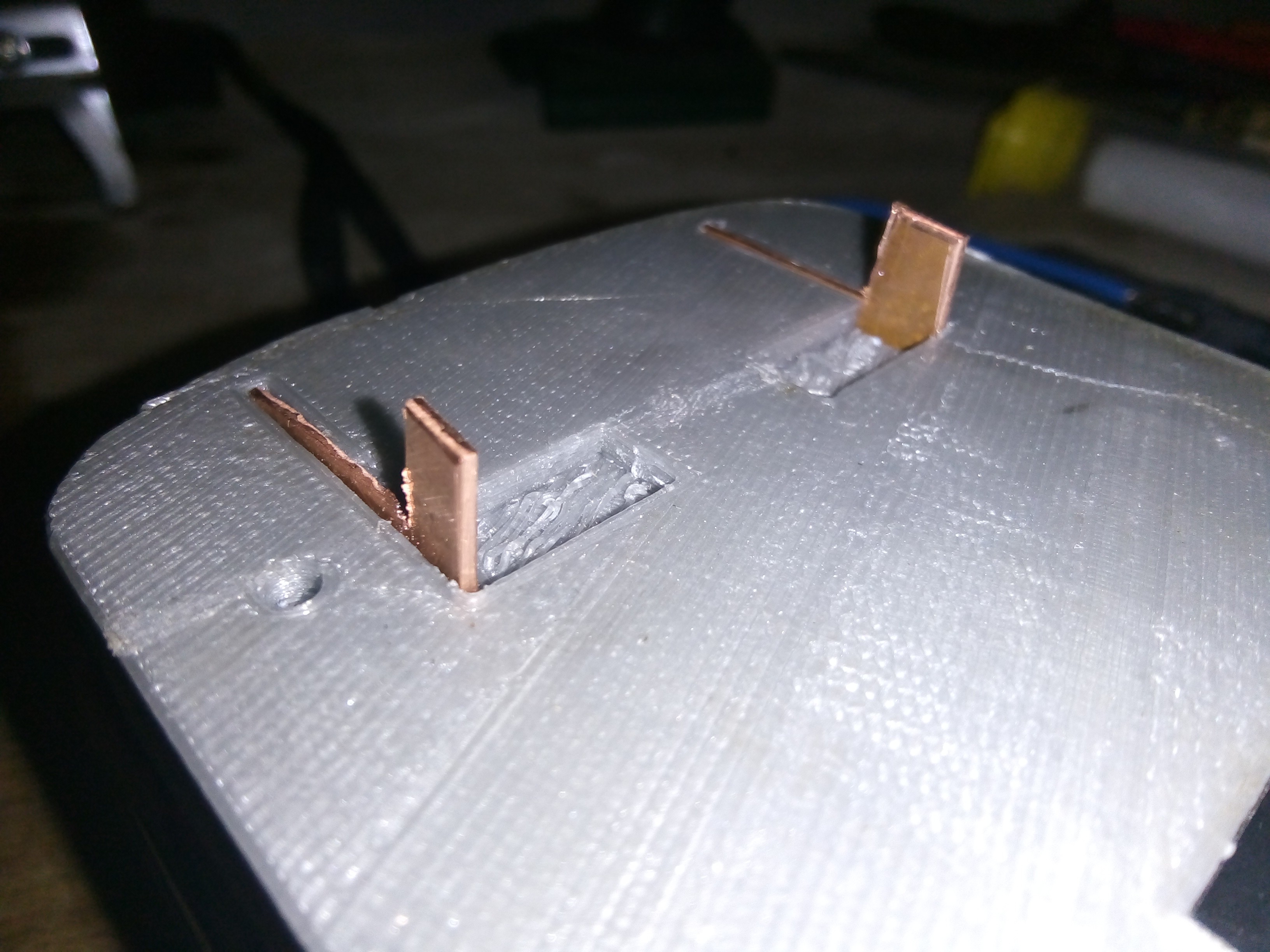

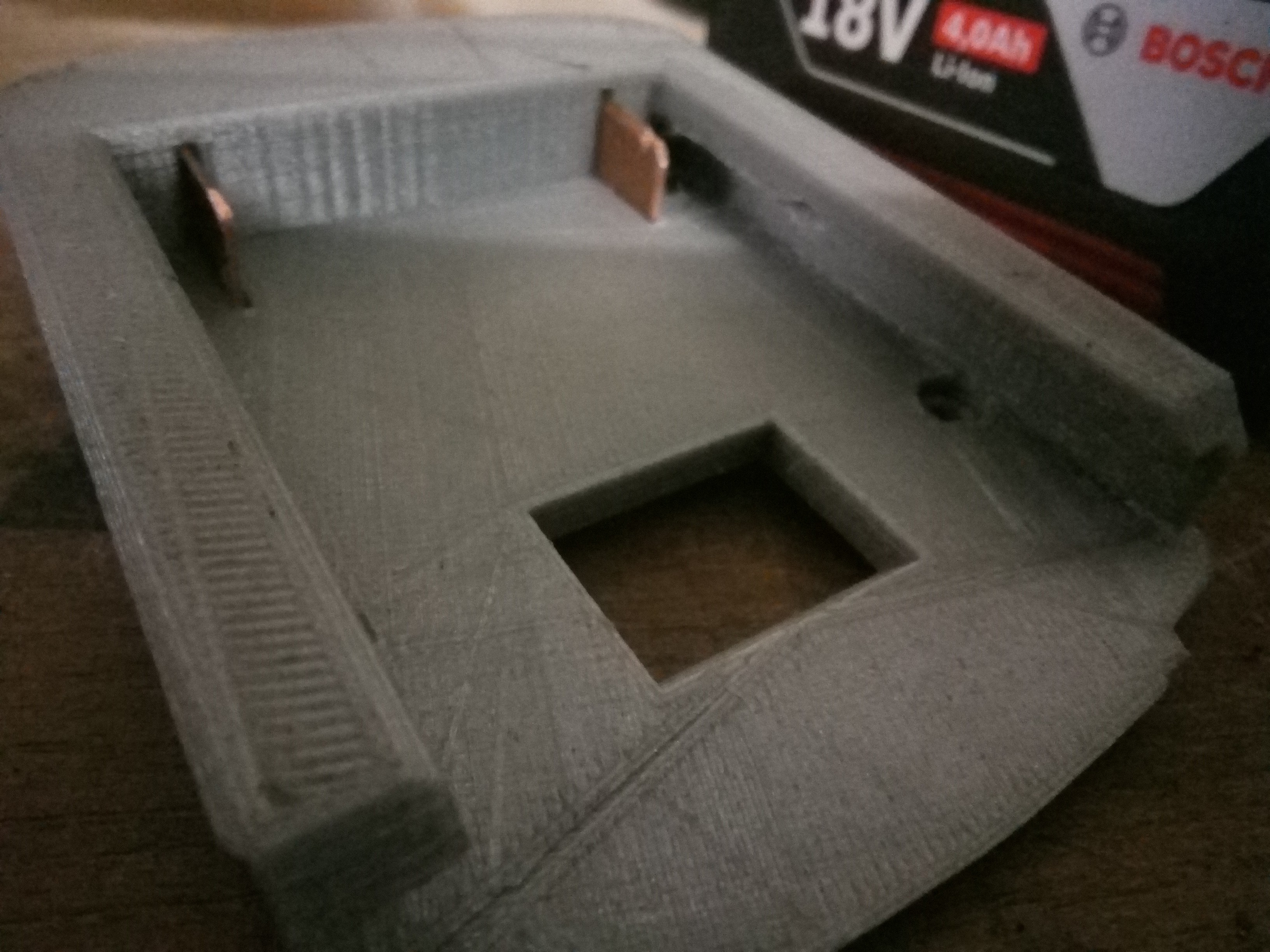

Simhopp's project is to make adapters for the most used drills to interchange batteries. Unfortunately no Parkside model in his library but I found Bosch Pro. 18v batteries socket 3d model. For efficiency matter, I decided to cut the old battery case and glue it to 3d printed part.

Now, Just do it !!!

NPN

NPN

In my case the connector was soldered to the board (the black piece on the PCB), so I de-soldered the board from the cells and then de-soldered the connector from the board's underside :

In my case the connector was soldered to the board (the black piece on the PCB), so I de-soldered the board from the cells and then de-soldered the connector from the board's underside :

morgan

morgan

sjm4306

sjm4306

Dimitar

Dimitar