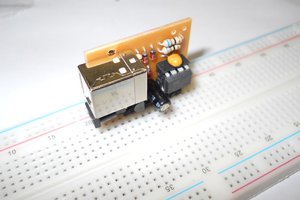

The T-Board was designed with the following in mind:

- Speed: Allow microcontroller prototyping on a breadboard, simply and quickly

- Ratsnest: Reduce the number of wires needed to prototype with microcontrollers

- Power: Allow the project to be easily self-powered, at either 5v or 3v3

- Programmable: Easily program using FTDI modules (for the ATmega328), or ICSP programmers

- Flexibility: Choose your own Crystal, so that you can experiment with low-power modes.

Andrew Retallack

Andrew Retallack

DIY GUY Chris

DIY GUY Chris

Neven Boyanov

Neven Boyanov

danjovic

danjovic

Alex Martin

Alex Martin

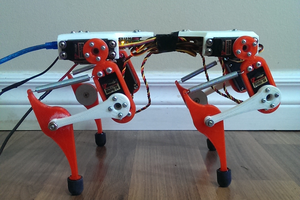

The T-Board has evolved into the Toadstool. Check it out here:

https://hackaday.io/project/4234-the-toadstool