New board, 9000 lines of software, resistive load, drill-press frame.

I managed to pick up a bug which slowed me down a little this week. Just wrote software and did a few minor tasks.

Someone at my space works for Linear Technologies (!), and knows LTSpice (!), and is an electronics designer, and has agreed to help me simulate the driver board and adjust it for clean output (!!!). When he comes back from vacation, in about 2 weeks. Woot!

Sorry for the haphazard placement of images and text. I'm finding that it is nigh impossible to predict what the Hackaday.io system will show after something is published. It's not WYSIWYG - things change after posting.

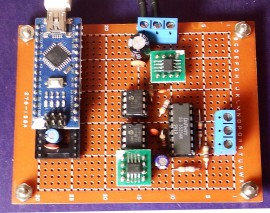

I made a "soldered" version of the control board. I'm hoping everything fits in a 4"x4" area, so that an ATX PSU case can be the project enclosure. Note: socketed Nano can be removed and used for other projects. I think I'll make that a part of the board design.

Remaining tasks:

a) Tune the driver board for clean output

b) Finish schematic capture of version 1 design

c) Board layout

d) Get some boards made

I had some leftover I/Os on the Arduino Nano, so I decided to add some features:

a) Two digital inputs, which can be linked to the transducer by user commands: on/off control, triggered on-time, ESTOP, and so on.

b) Two digital outputs, which can be controlled by user command or linked to system functions (ie - "on" when transducer is on)

c) Two LED outputs which show system state

d) I'm thinking of adding a sonalert, so the system can beep when the xducer turns on.

e) The extra I/Os will be optoisolated, for robustness.

Other than these features, I can't think of anything else the system needs.

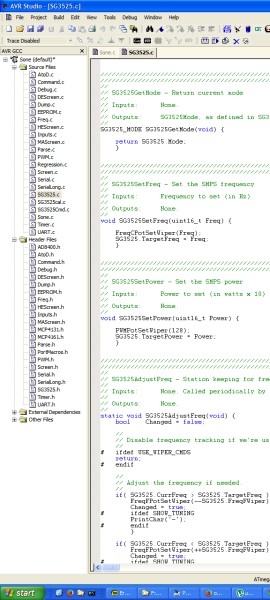

I've got 1200 lines of executable code (semicolon count) in 9000 source lines across 48 source files, all of which seems to work.

Remaining tasks (software):

a) Measure current usage and calculate power

b) Implement power tracking system

c) Code to implement the extra features mentioned above.

I'm working up a new demo of the system in action - plastic welding or liquid mixing.

Here's the 50-watt transducer mounted.

Here it is, mounted on some standoffs for heat dissipation.

Peter Walsh

Peter Walsh

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.