TL;DR: First attempts at Ammonia production will begin in a couple of weeks.

I hope to have everything done and making first attempts at Ammonia production by August 17th, the Hackaday entry cutoff.

LEFT TO DO:

.) See if the power output can be tuned to a sin wave

.) Clean up/finish the power output board

.) Minor improvements to the controller board

.) Schematic capture/board layout of complete system

.) Get PCBS made for power supply

.) Final assembly of Ammonia production system

.) Make power supply plug/interface for mass flow controller

.) Make a couple of demo videos

Secret System

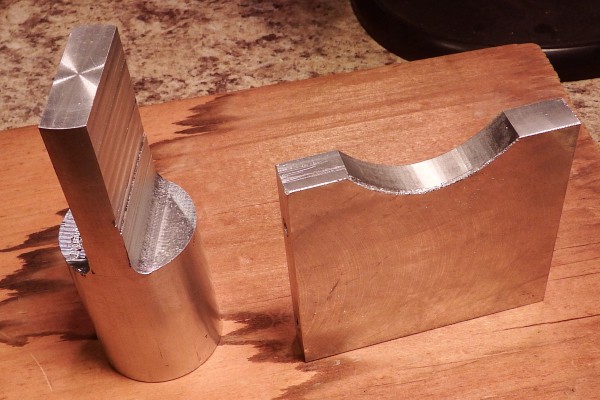

Here's a sneak peek at the the secret system.

The whole purpose of this Hackaday prize entry is based on these two pieces.

How are they used? What are they for?

All will be revealed in a couple of weeks.

Updated resonance program

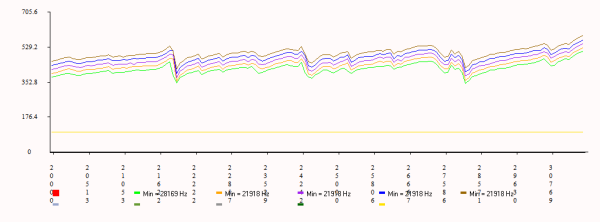

The next big project step is to get a tuned horn, so I spent some time updating ResonanceFinder to make this task easier.

The new version keeps and displays the previous 10 sweeps - now it's easier to see how the response changes during the tuning process. I also added some minor improvements and organized the directory better.

(The X-axis labels are messed up. That's apparently a bug in the graph library I'm using - I'll look into it later.)

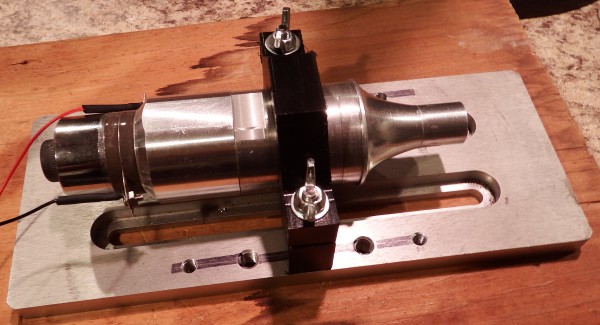

CNC mount for Transducer Horn

For proper resonance, a horn needs to be 1/2 wavelength long. Knowing the frequency of the transducer (28 KHz) and the speed of sound in Aluminum (5100 m/s) that comes out to about 91 mm of length.

In practice you always make the horn longer than needed and repeatedly shorten it while measuring the response. This usually involves many chucking and unchucking steps as you switch between lathe end-cuts and measurements.

The horn has a node 1/4 of the way along its length which doesn't vibrate during the measurement process. It occurred to me that I might be able to clamp the horn at that point and measure the resonance while mounted on a CNC mill, so I made up a mounting clamp.

If this works it will greatly reduce the effort needed to tune the horns. Testing/horn tuning starts tomorrow.

Updated resonance circuit

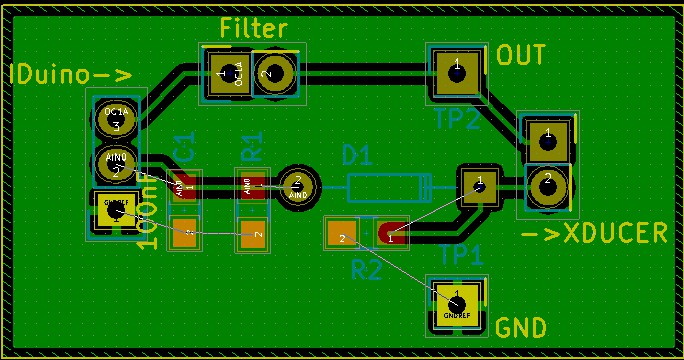

I added some convenience features to the interface circuit that sits between the Arduino and transducer, captured the schematic and made a board layout (and did some reorganization and administrivia).

The tuning circuit isn't worth having a board made, but I routed the PCB just in case someone doesn't want to hand-wire one. See below.

All files will be available on GitHub after the contest: source programs, CAD files for mounts and holders, circuit schematics and board layouts, and documentation.

(I'd make everything available now, but I'm putting off tasks that doesn't directly contribute to the prize until afterwards.)

Miscellaneous

Someone at my hackerspace makes mass flow controllers for a living... and gave me one! (Woot!)

This is/was the final piece of the system I was looking for. All that's left is putting things together and getting them to work.

Thanks Dave! You're awesome!

Peter Walsh

Peter Walsh

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

I'm looking forward to this so much. This is awesome.

Are you sure? yes | no