What a journey this has been! And it's only just getting started!

As I said below, I have my first batch of PCBs back! Work got in the way a little bit and I've not had an opportunity to get them soldered up, that is, until now.

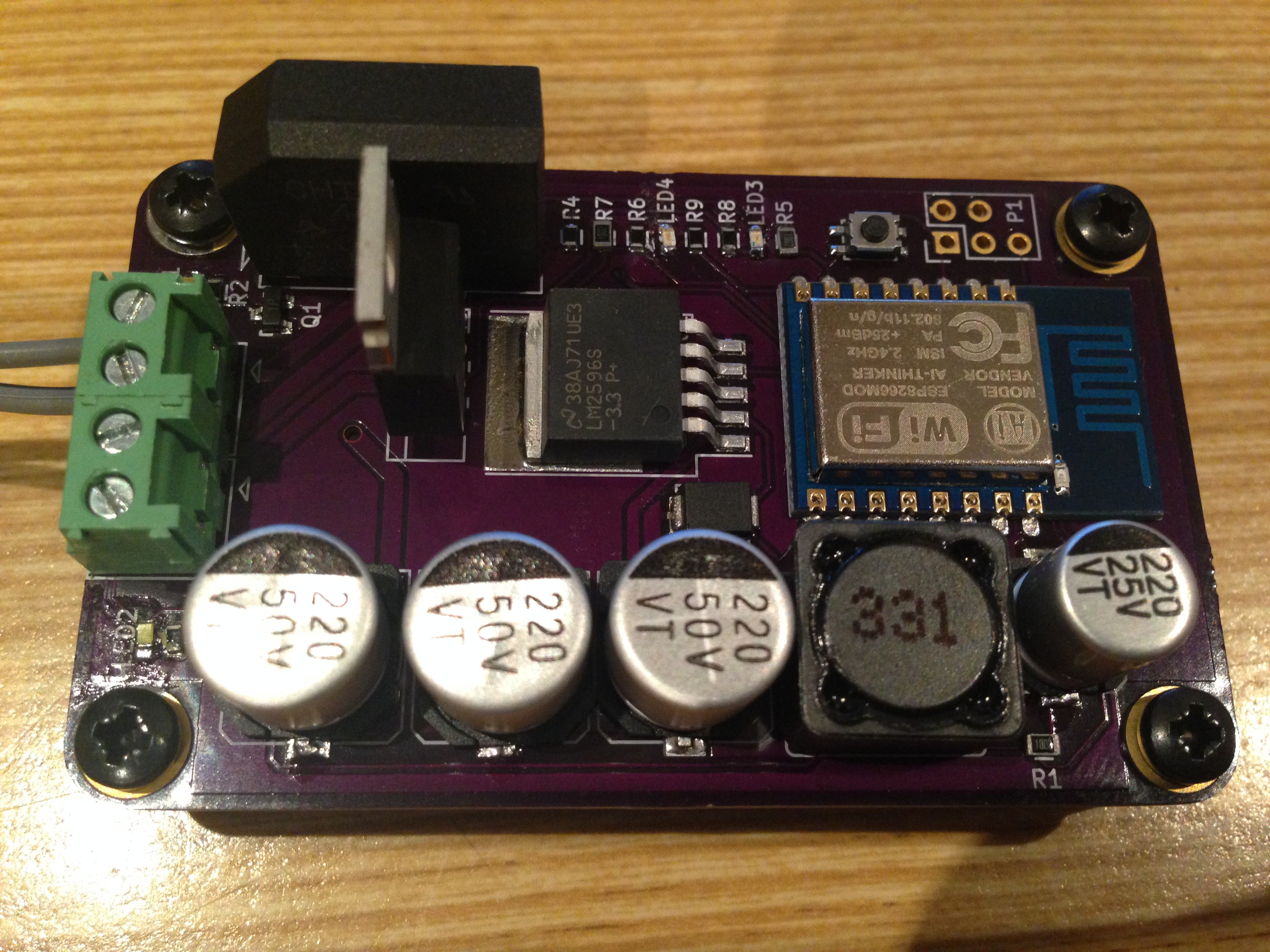

Here it is! It works! (mostly)

The road to getting to this point has been a little bit rocky! Lets take a bit of a step back in time to before the board was all soldered up. First up, I have learnt an important lesson about solder paste. When they say it has a shelf life, they are right. When they say to get good quality paste, listen! The stuff I have is pretty terrible. The first few boards I made up went alright. Spreading the paste on this board a few months later is horrible. I guess it is time for some new stuff.

Here is the board in its pre-soldered, but post populated state:

To me, everything looked great. There probably should have been a little more solder paste in spots, and I did touch them up a bit, but I thought it'd be fine. Onwards and upwards! I threw it into my brand new Zallus reflow oven. I've tested a few boards with a couple of smaller parts on them, and it's been working great. I think it might have been more luck than good management, because throwing my board in didn't quite go to plan. I think my reflow profile was a little bit on the low temp side, or my solder paste truly is an abomination. Anyway, the oven went ding, I pulled it out and the bigger parts hadn't fully reflowed. The controller did its job beautifully, just the bag of meat behind the controls hadn't set it up right. I knew that I wasn't supposed to reflow a board that has already gone through the oven, but I don't really have any other options. I rebuilt the profile with settings that (should) work, and powered on! I put the board through the oven again and bingo, all the solder melted properly.

I soldered the few through hole parts in, wired in my lab power supply, held my breath and turned it on... None of the LEDs lit up. I should at least see LED4, the power indicator. The power supply showed that it was pulling current, so I measured voltages, power was getting to the LED properly, so that meant that all the components in-between were working fine. I then plugged up my programmer board, installed the latest NodeMCU, and switched on the indicator lights, LED1 and LED2. Power, but no lights. I then switched on the main LED output. LED3 didn't light up but I had power at the output terminal. By this stage I had figured out what I had done wrong. I had misread the silkscreen and put every one of the LEDs on backwards. 'Double face palm!' as Dave says.

After a fiddly job of pulling the LEDs off and hand soldering new ones on in the correct direction, they all worked! Next up, I tested the little button which will hopefully reset all the wifi settings. Unfortunately, I screwed up here. The schematic has the ground symbol not connected to the other leg of R5. Doh. Looks like a bit of a bodge is needed. I scraped off some of the solder mask just above the resistor and dumped a bunch of solder in it. Problem solved! I think I probably could have used the internal pull-down resistor in hindsight .. I'll give that a shot on the next board. You can see the bodge on the resistor to the left of LED3.

So far, everything seems to be in order. I haven't tested AC in yet, nor have I plugged an actual LED globe into it. It is getting late, and I think it is a job for another day.

My next task is to get this firmware sorted. What I thought was going to be the easiest part is giving me a bunch of grief. Oh well. I'll also get my laser cutter and 3D printer out soon so that I can build up a case. If I do get these made in any kind of volume, I don't think 3d printing is the way to go. I can either stack multiple layers of perspex together, or get them manufactured somehow. Injection molding perhaps?

We aren't too far away from having something I can set up and test in place! Thanks for reading!

Matt

Matt

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.