I uploaded a video where I ramble about my intentions of building this robot.

I mention some of the parts I plan to use with the robot and give a general overview of my plans.

Here are a couple of photos of the two tread sections I've built so far.

The structure closest to the camera was made from expanded PVC (ePVC). The other structure was my first prototype and it was made from foam board. Foam board was used to see if the planned geometry would work correctly. Before making the second prototype, I changed the design of the motor mount in order to increase its strength and stiffness.

Below is a closeup of the ePVC motor mount.

I used two thicknesses of 3mm ePVC in some parts of the motor mount. Since making the above prototype, I've purchased some 6mm ePVC which I plan to use in future prototypes.

I used two thicknesses of 3mm ePVC in some parts of the motor mount. Since making the above prototype, I've purchased some 6mm ePVC which I plan to use in future prototypes.

Vex wheels and sprockets use a square drive hole. To mount the Vex sprocket to the motor's 6mm shaft, I drilled out the center of the sprocket and then drilled a hole from the side of the sprocket to the center hole. I added a 4-40 machine screw with a nut to the sprocket to act as a set screw.

To reinforce the sprocket, I added Polymorph to the open areas on one side of the sprocket.

The set screw is positioned so it doesn't interfere with the tread. The nut embedded in the Polymorph is necessary since the plastic alone would soon strip and not provide anything for the set screw to push against as it clamps down on the "D" shaped drive shaft.

The set screw is positioned so it doesn't interfere with the tread. The nut embedded in the Polymorph is necessary since the plastic alone would soon strip and not provide anything for the set screw to push against as it clamps down on the "D" shaped drive shaft.

Here's a photo of the sprocket secured to the motor with the treads installed.

The Polymorph helps the sprocket hold its shape as the set screw is tightened.

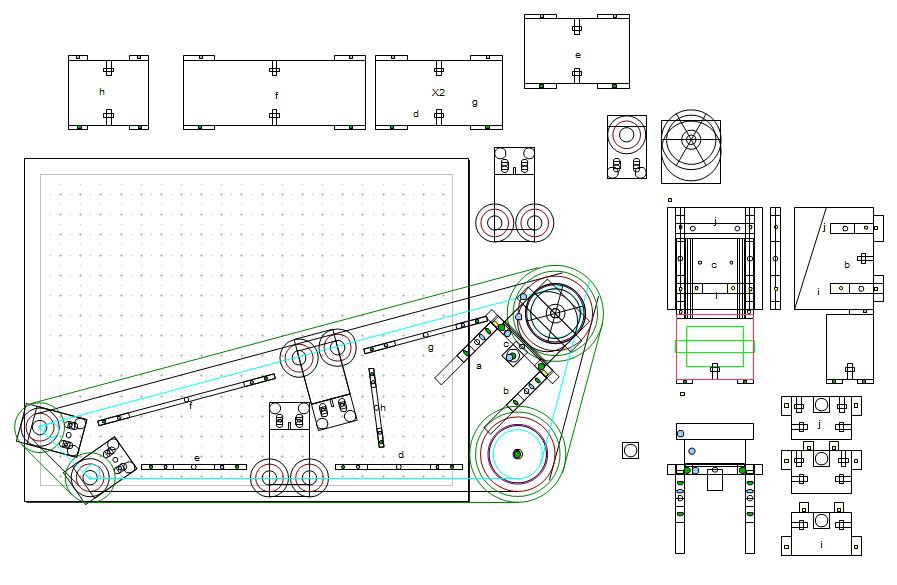

I drew the parts with OpenOffice's Draw program. Here are most of the pieces before they were laid out to fit on a sheet of paper.

After the parts were arranged to fit on a sheet of paper and printed, they were cut out and glued to the ePVC. I used a Dremel with a saw wheel to rough cut the shapes. I used a milling bit in a drill press to cut the slots. I finished the pieces with a belt sander and X-acto knife. Cutting the pieces this way was very labor intensive.

I have a CNC router which is currently not operational. I think I will spend some time getting the CNC router working before continuing to build this robot.

I also plan to modify the design a bit. The rollers farthest from the motor need more support than the ePVC frame provides. I will likely reinforce this area with some aluminum L-bracket material. I also intend to add bearings to the unpowered sprocket.

Besides the changes I plan to make, I also have large sections of the robot I haven't begun to design. I have some thoughts about how to articulate the tread structures but I haven't tried any of my plans out in the real world yet.

I would really like to get the basic hardware finished relatively soon so I can begin working on the code to control the motors and tread movement. I have a feeling getting this robot to climb stairs autonomously will be a very big challenge.

Duane Degn

Duane Degn

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.