Introduction

Our initial method of creating fingers for robot and prosthetic hands was very simple and it didn't require any complex tools (silicone sheets were stitched onto the rigid phalanges with simple needles). The main disadvantages of this method are: 1) the process isn't automated, 2) the aesthetic aspect of the finger is not optimal (i.e., it doesn't feel like a product), 3) the finger cannot easily accommodate extra parts (e.g., sensing elements or other electronics). For these reasons we searched different fabrication methods for developing hands based on flexure joints.

Recently Ma et al [1] proposed a new methodology that is called hybrid deposition manufacturing (HDM). HDM combines additive manufacturing (AM) with multi-material deposition and embedded components in order to produce robotic, mechatronic, and other articulated mechanisms.

Design

Using the HDM approach for our prosthetic fingers we can embed inside them a wide range of electronics, like force sensors, flex sensors or even NFC tags that will facilitate interactions with other electronic devices. Of course the new design has the disadvantage that it requires more complex tools and is slightly more expensive.

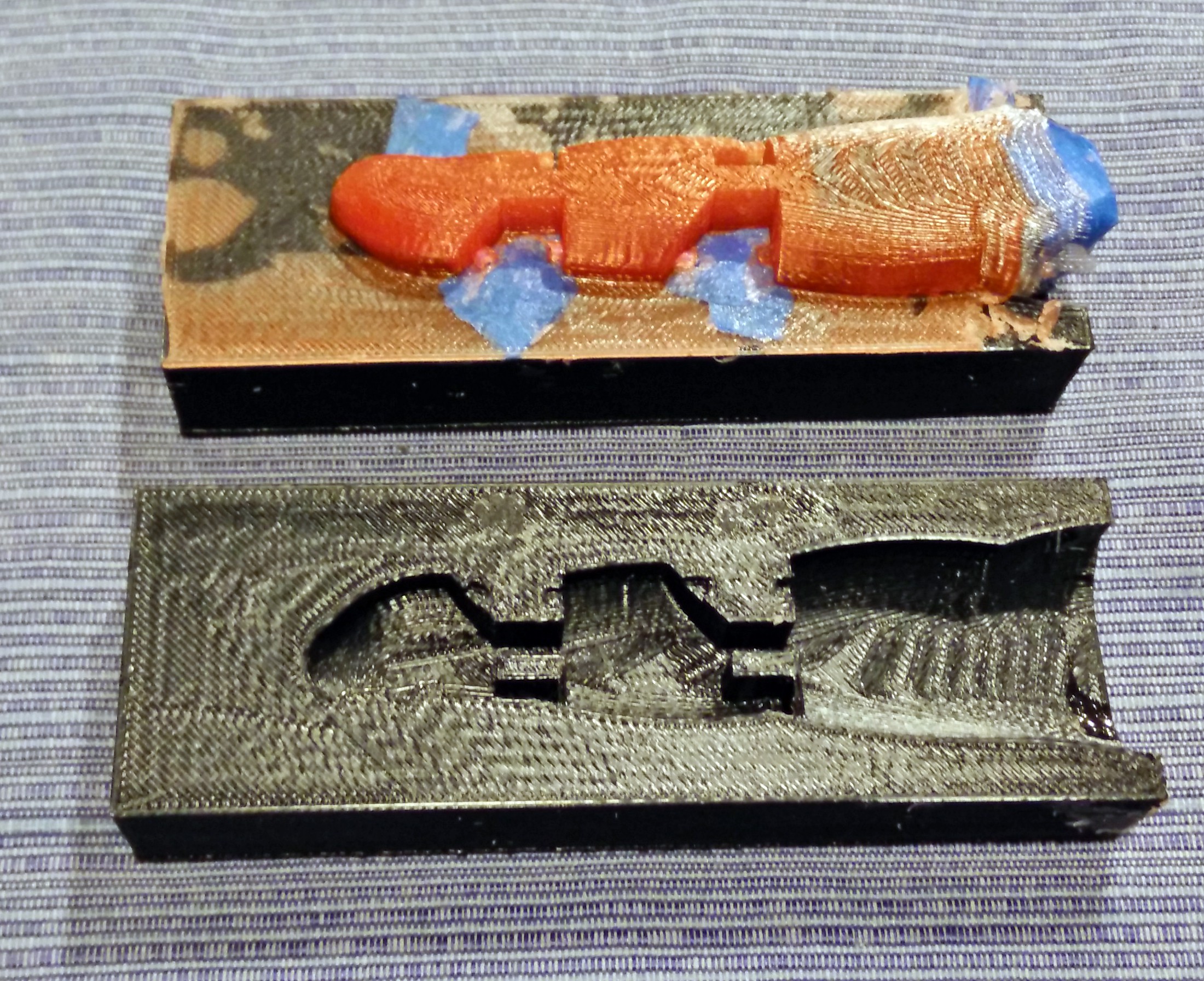

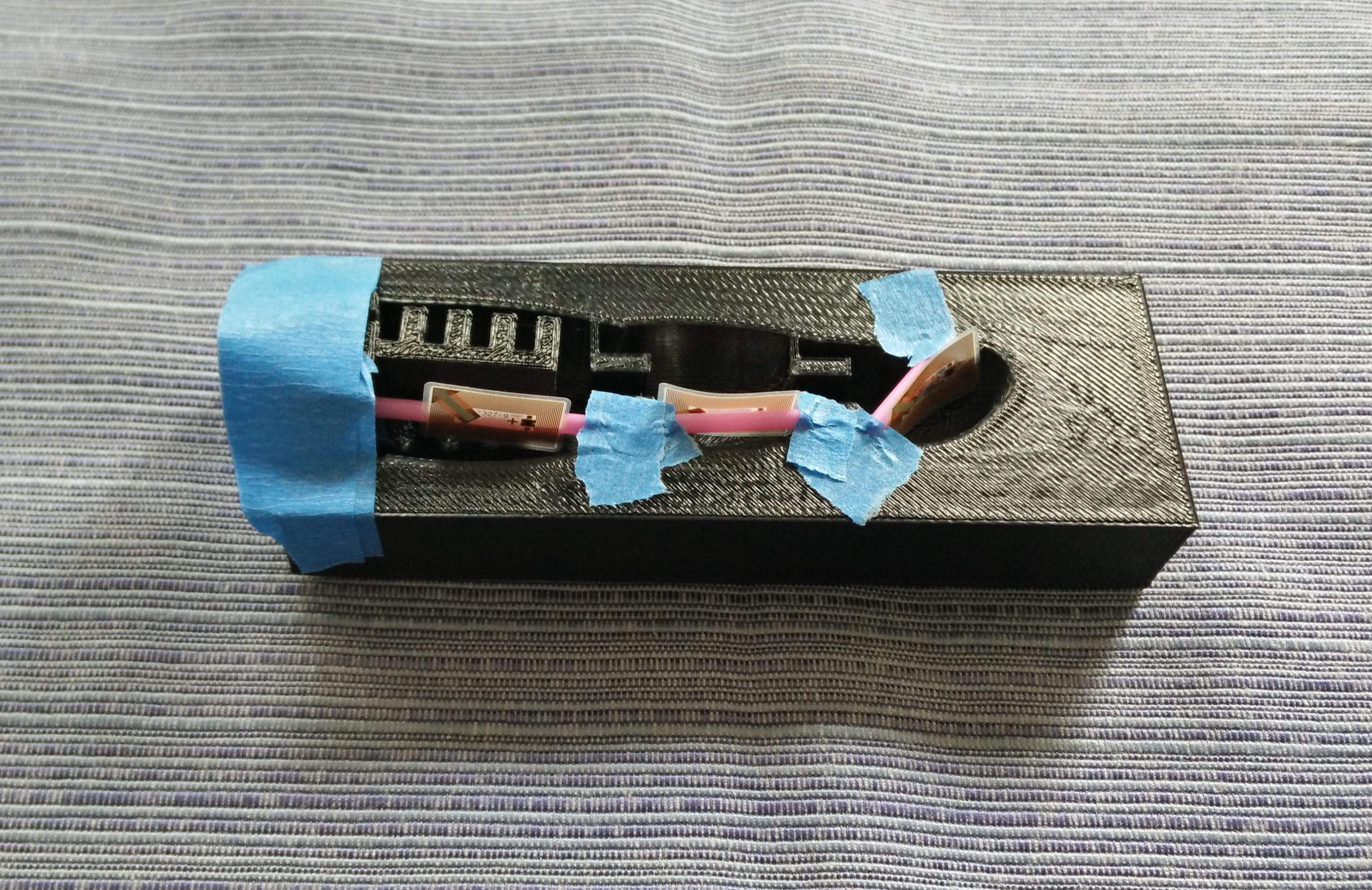

Figure 1. The mold and the 3D printed finger base.

Figure 2. The mold opened. The new finger design is also depicted.

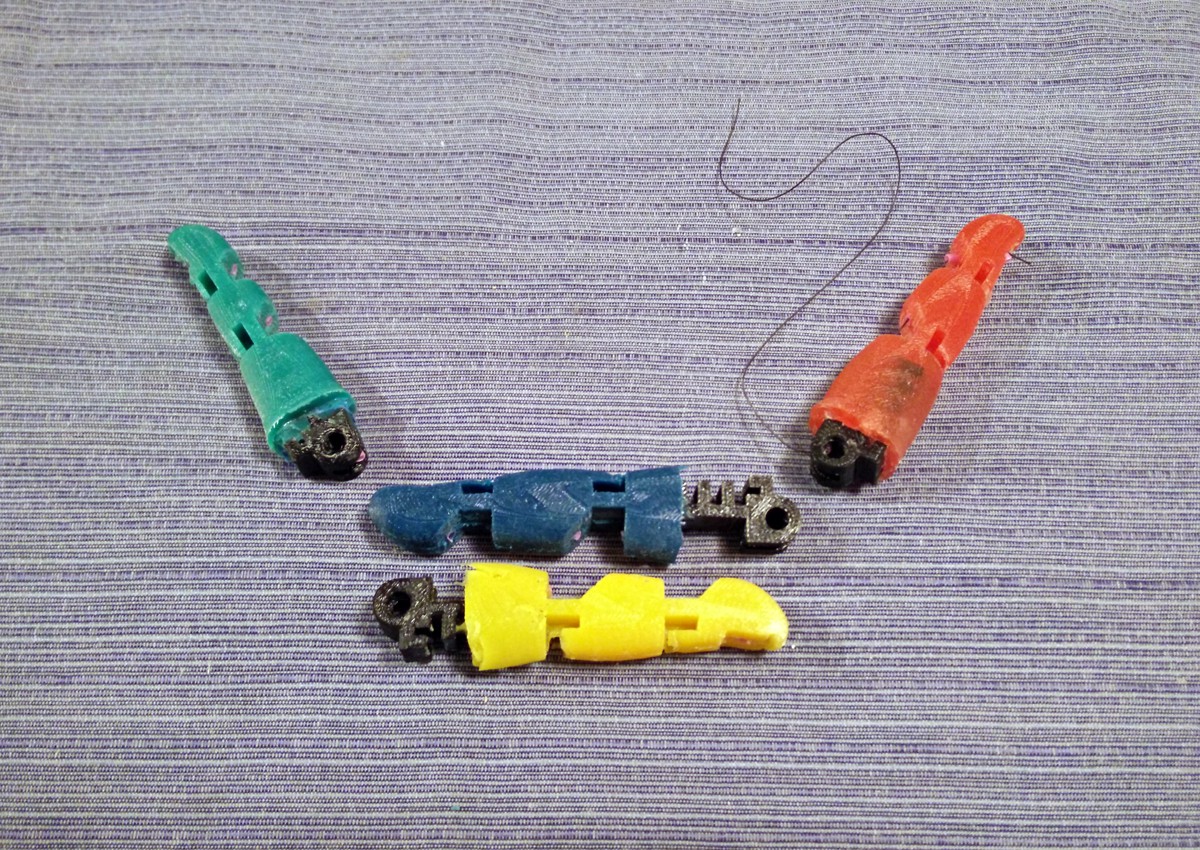

Figures 3. Fingers created with the HDM technique using different colors. As it can be noticed the proximal is now a pin joint, in order to reduce the effect of the torsional forces in the finger configuration and the out of plane motion of the finger.

The proposed design can be based on the human hand model. For now we use a ready model in SolidWorks. In the future we plan to use a 3D scanner (e.g., kinect, project soli, etc.) to reconstruct the intact hand of amputee, derive the mirror hand and build a personalized prosthesis.

To use this new design in SolidWorks, you can download the files form here. When you open the .sldASM files, SolidWorks will ask for the missing parts. These parts can be found in the following 3D model. A future direction of ours is to make the HDM design parametric and migrate it to FreeCAD, as we did for the initial design.

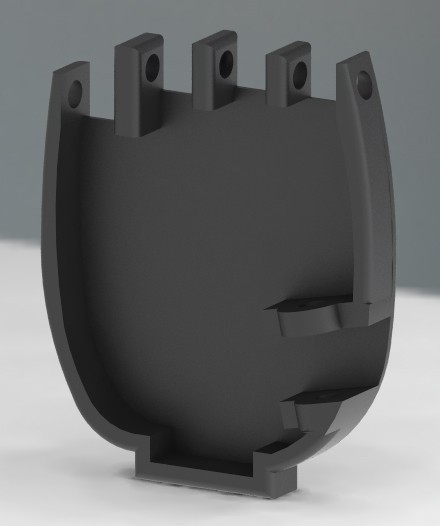

It must be noted that the new fingers are completely modular. We want amputees to constantly use our hands and we hope that they will break them. We expect that the most frequent damages will happen to the fingers that can be easily replaced. After all the design is so affordable that each user may have several spare parts. In the following figure we present a preliminary design of the new palm, that will accommodate the new HDM fingers (the differential mechanism has not been incorporated yet).

Figure 4. A preliminary version of the HDM design palm.

Materials and Tools Required

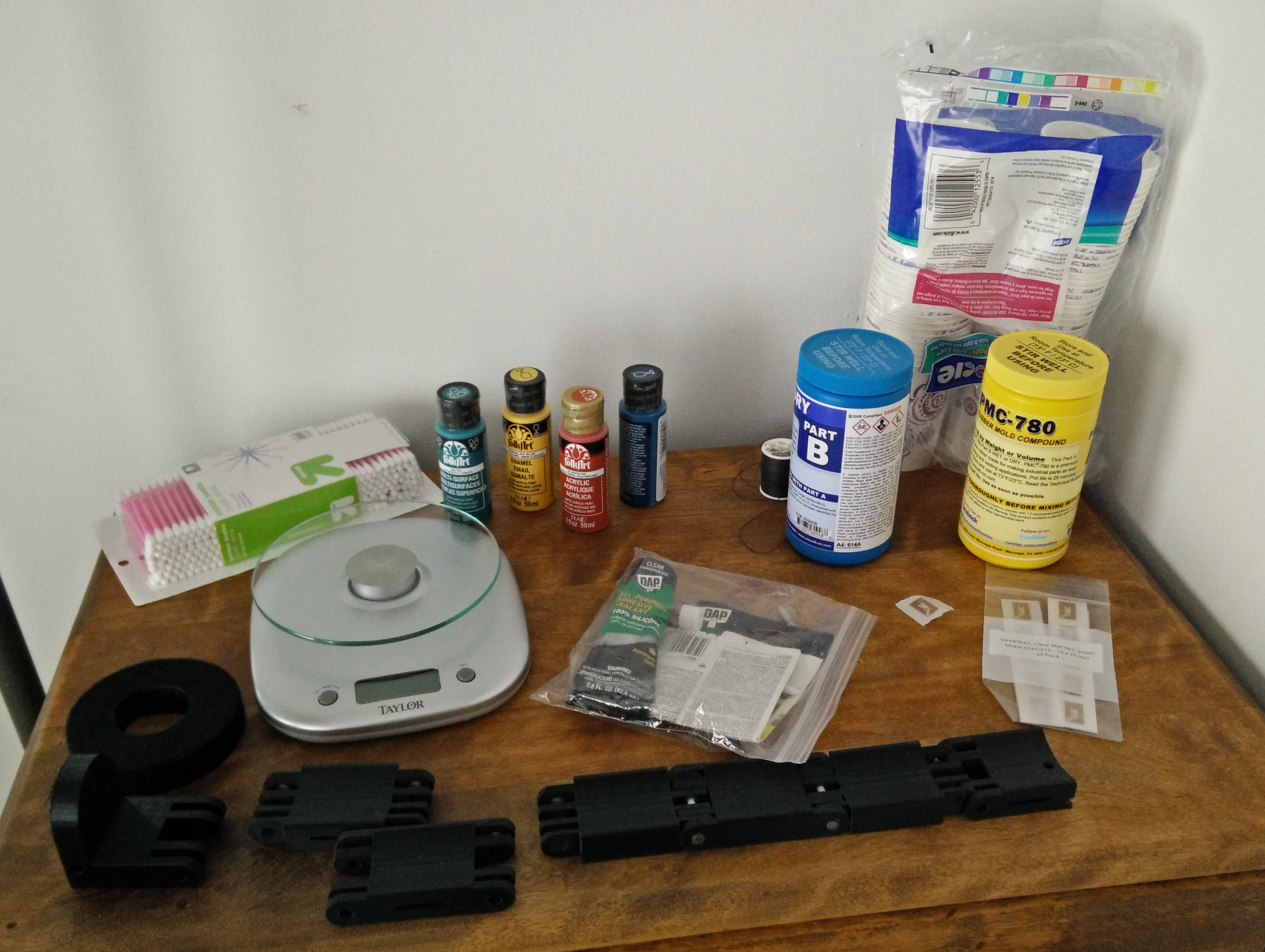

As depicted the build of materials are:

* paint of the desired color

* liquid polyurethane (PMC 780)

* cotton swabs

* paper tape

* NFC tags

The necessary tools are:

* a weighting scale

* a vacuum chamber

* plastic cups to mix the two liquid silicone parts.

The prices of the different hand components can be found here. The NFC tags cost 15.50$ (for 25 tags).

Figure 5. Some of the tools required for the replication of the HDM based prosthetic fingers. A weighting scale, the NFC tags, paints of different colors, cottons swabs (that are used for the tubes), packages of polyurethane (PMC 780) and plastic cups are depicted.

NFC Ready Fingers

As we have already mentioned, with the HDM process we are able to embed inside the finger various electronics like a set of NFC tags. We had the idea to do this, when we read a Hackaday article regarding near field communications.

Figure 6. The left part of the mold, the 3D printed finger base, the low-friction tubes and the NFC tags are depicted. One NFC tag is used for each phalanx of the finger.

The NFC ready fingers can be programmed to interact with various electronic (NFC ready) devices. For example the amputee may touch his smartphone with the index finger of the prosthetic hand to open a specific application or with the middle finger to tune the radio to his favorite station. More details on how to program NFC applications for android based devices can be found here.

Experiments

The new finger design performing unconstrained flexion, can be found at the following video:

Exemplar applications of the NFC ready fingers, can be found at the following video:

References[1] Raymond R. Ma, Joseph T. Belter and Aaron M. Dollar, "Hybrid Deposition Manufacturing: Design Strategies for Multi-Material Mechanisms via 3D-Printing and Material Deposition", Journal of Mechanisms and Robotics, 2015.

OpenBionics

OpenBionics

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.