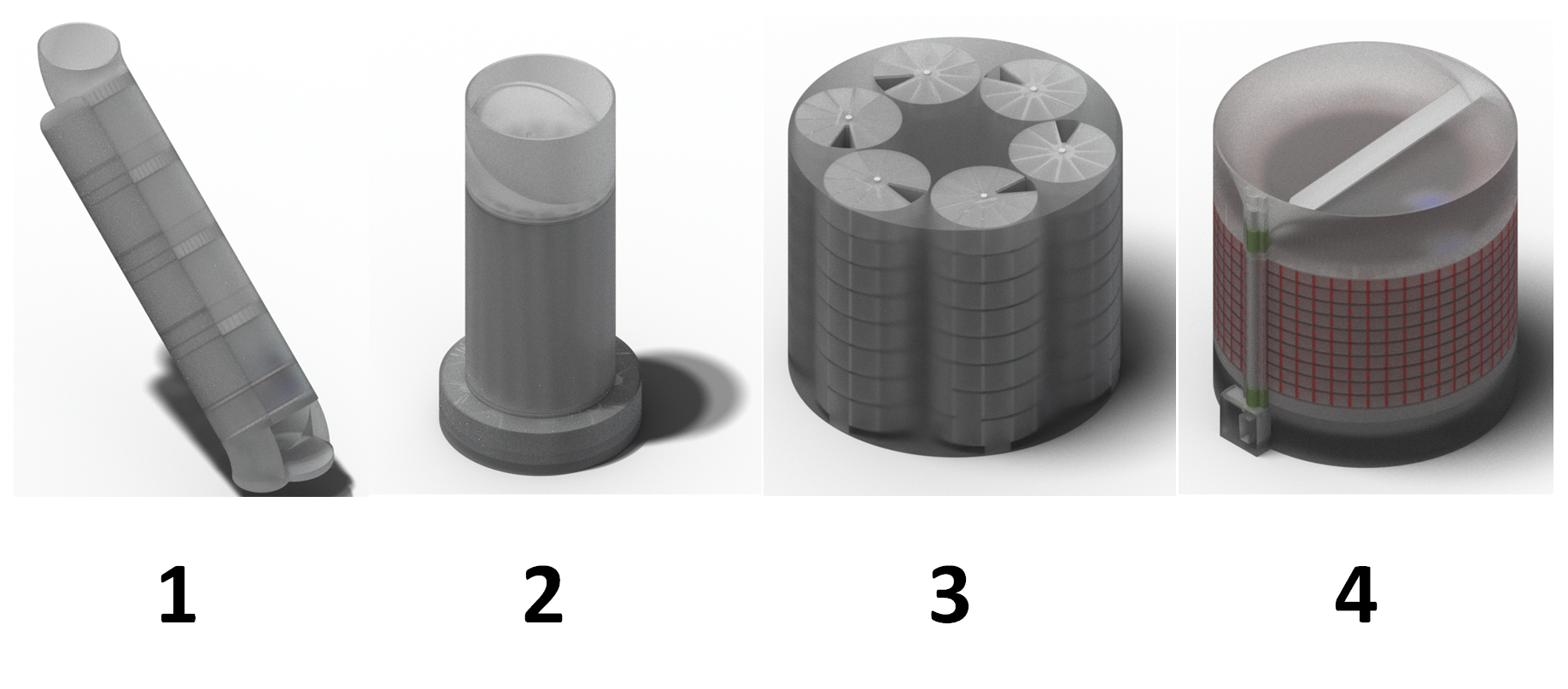

Up to this point, four virtual prototypes have been made.

- Rotating Plate

- Tube

- Cascading Container

- Stacked Container

I've learned a lot making these prototypes - more than I can possibly write about. Let my try to give a general outline of what the machine should do.

- Accept Pills

- Separate, catalog and verify if necessary

- With as much automation and as little required dexterity as possible

- Store Pills

- Pills can either be stored in an orderly manor or in bunches; in containers or tubes

- Dispense Pills

- Separate, verify if necessary

- Verify pills have been taken

- Easy to use/take pills

| # | 1 | 2 | 3 | 4 |

| Name | Rotating Plate | Tube | Cascading Container | Stacked Container |

| Accept Pills | TBD, Requires verification | TBD, Does not require verification | TBD, Requires verification | TBD, Requires verification |

| Store Pills | Stored in containers, Not orderly | Stored in tubes, Tube must match pill type, Orderly | Stored in container, Orderly | Stored in container, Orderly |

| Dispense Pills | Rotating plate, Plates must match pill type | Reciprocating plate (Probably), Plate must match pill type | Rotate storage mechanism | Rotate storage mechanism |

| Notes | Simple but requires mechanism changes | Simple but requires mechanism changes | Complex | Complex |

In working with these designs, I've (probably) narrowed it down to two choices: the tubes (#2) and the stacked containers (#4). I'm not sure I can properly explain the design decisions, but I believe these mechanisms represent the best choice for two competing strategies.

If we assume that people buy this device, bring it home, and use it with their existing medication, a stacked container (#4) is best. If we go with the ink-jet model where people buy "cartridges" from a pharmacy or online. the tube (#2) is best.

I envision the stacked containers (#4) to be quite complex, but versatile (able to accept pills from prescription bottles). Pills need to be separated, verified, and added to a container. Dosage data also needs to be imputed. Pills will then be dispensed and verified again.

Using concept #2 (the tubes) bypasses a lot of steps. Pills will be put in the tubes at the factory/pharmacy and verified. Placing a cartridge (tube) in the machine would be easy, and the dispense mechanism would be built into the individual tube (haven't figured that out yet, but I envision something similar to a pen or mechanical pencil). The dosage data could be pre-loaded onto the tube (NFC). The machine would only have to keep track of the tubes and activate the dispense mechanisms at the correct time - a considerably simpler process.

Now, the question remains - #2 or #4?

dthunes

dthunes

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Or gravity drop the tablet with a slot exactly one pill height and use swipe arms to remove the tablet. More useful for managing several tubes at once. After the swipe, another tablet drops into the ready position

Are you sure? yes | no

For self-dispensing in the tubes, think Pez dispenser. Gravity drop (or spring-loaded) and a simple mechanism to push out the bottom tablet.

Are you sure? yes | no

Thanks for the ideas. I thought of a similar idea, but I couldn't figure out a mechanism I liked (that was small). If you have a good idea, please send me a sketch.

I was trying to go cheap and simple, and after trying a few different types, I came up with a system that uses a strip of spring steel to push the pill. I'll need to prototype and make sure it works, and also see if I can use plastic instead of steel.

I'll do a write up soon.

Are you sure? yes | no

What are you using for actuation? The mechanism would be quite dependent on that. A Pez dispenser just uses a spring loaded lifter and a tab that pushes the candy out when you tip the head. Just a cam basically.

So, from the bottom, instead of the top, you use a light spring to push the pills down and at the bottom you have a C shaped part on a hinge. You pull on one end of the C and the other end pushes. If it has a spring return you just need to bump it to dispense a pill.

Or a strip of spring steel like you suggest. If attempt to shorten its length by pinching it, it will bulge. If you restrict the bulge, it will apply the push where you want it. So, say fix the strip on one end and have the other end sticking out to be bumped. When that end is bumped, it bulges in the center pushing out your pill.

Lots of options really.

This would require pills to be the same size/shape unless you have specific dispensers for each pill. My vision of your device would probably come up with a standard for the dispenser and put the burden of making the cartridges on the pill manufacturer or pharmacy to package them for use in your dispenser.

Are you sure? yes | no

Thanks for the ideas! I've done a lot of virtual prototyping, and will be 3D printing two concepts (this week).

I'm still experimenting with actuation methods - looking at motors, linear actuators, lever assemblies, solenoids, magnetic coupling, etc. Unfortunately, I have to figure out what the dispensing mechanism is before advancing too far.

I agree with the need for a standard dispenser, which will probably push the design closer to a PEZ mechanism. I think the mechanism will also require some sort of seal to keep the pills from absorbing the air moisture.

Unfortunately my digital concept renderings didn't turn out, so I won't be able to share much until I get the physical prototypes in-hand.

Are you sure? yes | no