The very first PCB I assembled was populated using tweezers but it didn't take long to realise that tweezers are not very efficient for a number of reasons:

- There's not enough space around a component in the tape to get the tips of the tweezers in and pick up the part.

- If the components are densely packed on the board the tweezer tips get in the way of placing them

- Trying to release the component without disturbing it's placement is remarkably hard when you have to move your placement hand to release the component.

I'd watched Mike from Mikeselectricstuff use a piece of tube with a blunt needle to pick and place parts with the vacuum supplied by sucking on the end of the tube. Although somewhat awkward to use, this setup was enough to convince me that it was worth investing more into a proper vacuum pickup pen of some sort.

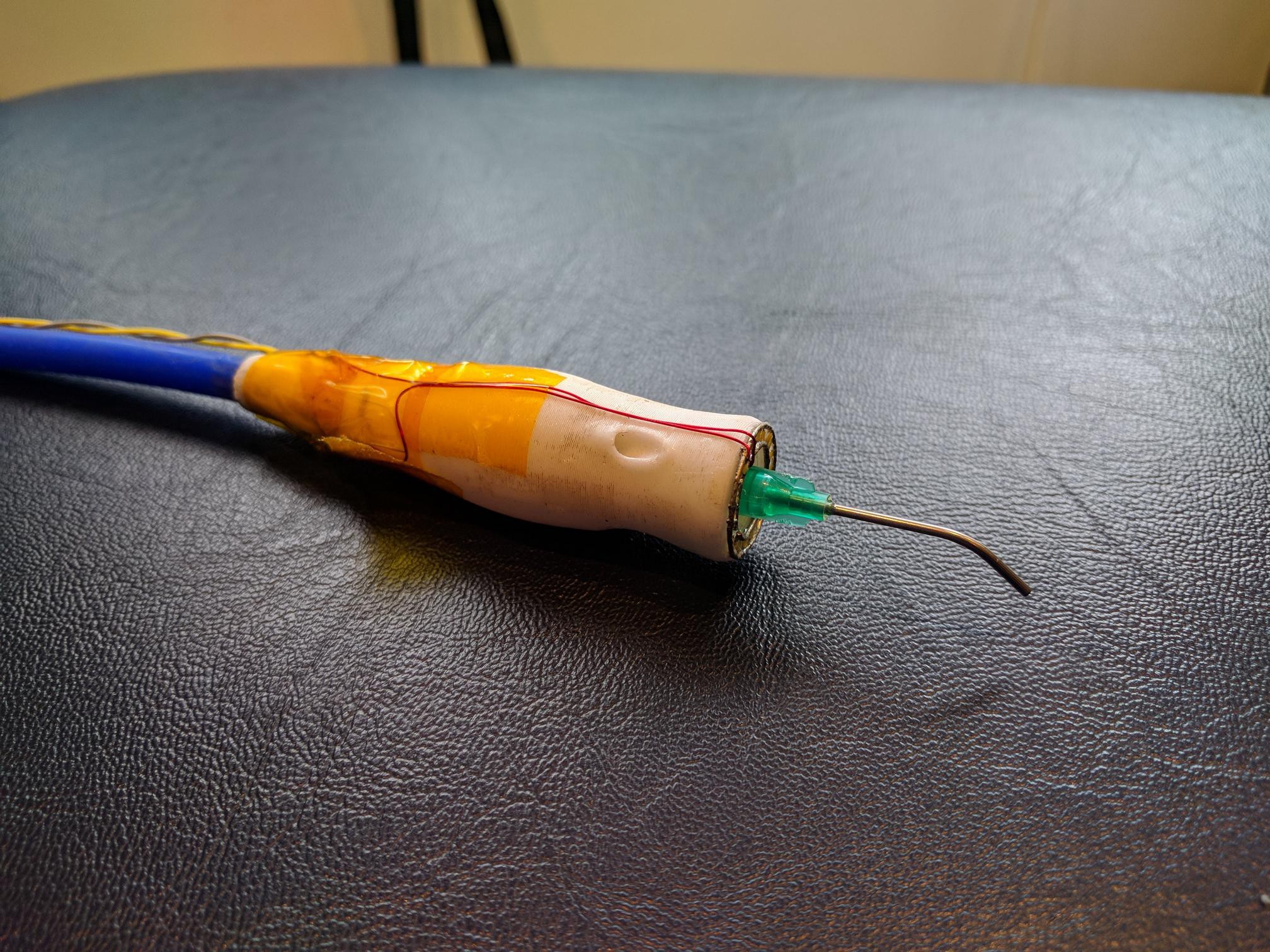

My first vacuum pick up pen looked like this although to begin with it didn't have the light ring. This is still a very simple setup, essentially this is a tube with a hose at one end and a needle at the other with a hole allowing you to control the amount of vacuum. The tube runs to a small, dc, vacuum pump that runs continuously. To pick a part up you would cover the hole with your finger creating a vacuum at the tip of the needle. One you have placed the part, removing your finger from the hole allows air in breaking the vacuum at the needle and releasing the part. This was a massive improvement over the tube-in-the-mouth setup but there were a couple of drawbacks:

- Once again, releasing the part meant moving the placing hand, this could easily disturb the part as it was being released.

- That thick blue silicone tube was too stiff and could make it difficult to place parts very accurately.

One advantage of this system is that by partially covering the hole you could regulate the amount of vacuum at the needle. With practice it was possible to have just the right amount of vacuum to pick up parts, place them and have them release from the needle once they were stuck in the solder paste without any movement of the finger.

I probably assembled over 100 PCBs with this setup, I added the light ring which was a huge improvement. I find that 0603 parts are really pretty easy to handle provided you have enough, and even, light. The LED ring provides light in exactly the right place and without any shadows.

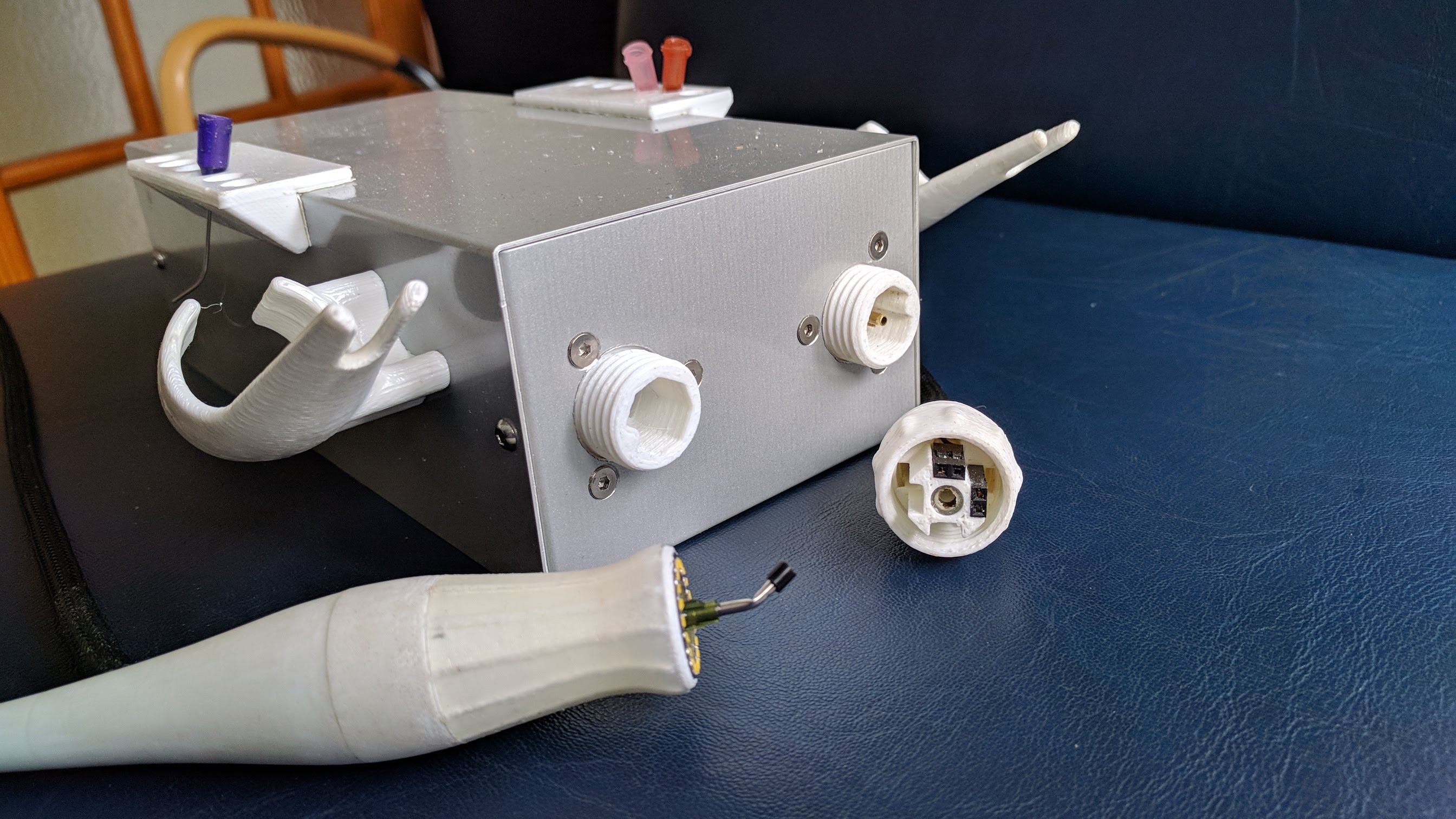

After a few months of using this system I wanted to try and improve it again. This iteration has a solenoid valve integrated into the pen body. The solenoid is controlled by a foot switch so finally I can place a part and release it without needing to move the placing hand at all. The pen is also larger in diameter and has a moulded silicone cushion to make it more comfortable to use for longer periods of time. The umbilical contains the wires for the solenoid and the LED ring which is now a proper PCB, having the umbilical enter half way up the pen reduces the amount it affects positioning the pen. I have various sizes of needle for the pen but typically I only use two, the one shown in the picture for larger parts and chips and a longer but thinner one for passives.

The vacuum pump is housed in this box which also houses a PWM speed controller and connectors for the pen (on the right) and the foot switch (on the left) as well as holders for the pen and spare needles.

Idris

Idris

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.