Ladies, if you joined HackaDay and learned to sew like a man, you wouldnt have to put up with that nonsense. It isnt a challenge, its just a statement of fact. The companies that make these things are run by men, and designers these days are predominantly still male. Not that they act like it, but thats IMO.

It's gone from abilities with no rights to rights with no abilities - only a small percentage of the population has the skills and its because of education. It just isnt taught anymore instead of being taught to all, and has become sophisticated by industry. You're being ripped off by the system, not supported by it.

Equal Rights, fine. Liberation, fine. Chauvinism in any form I dislike, and I will always pick at those seams when I encounter them. Here's what I found.

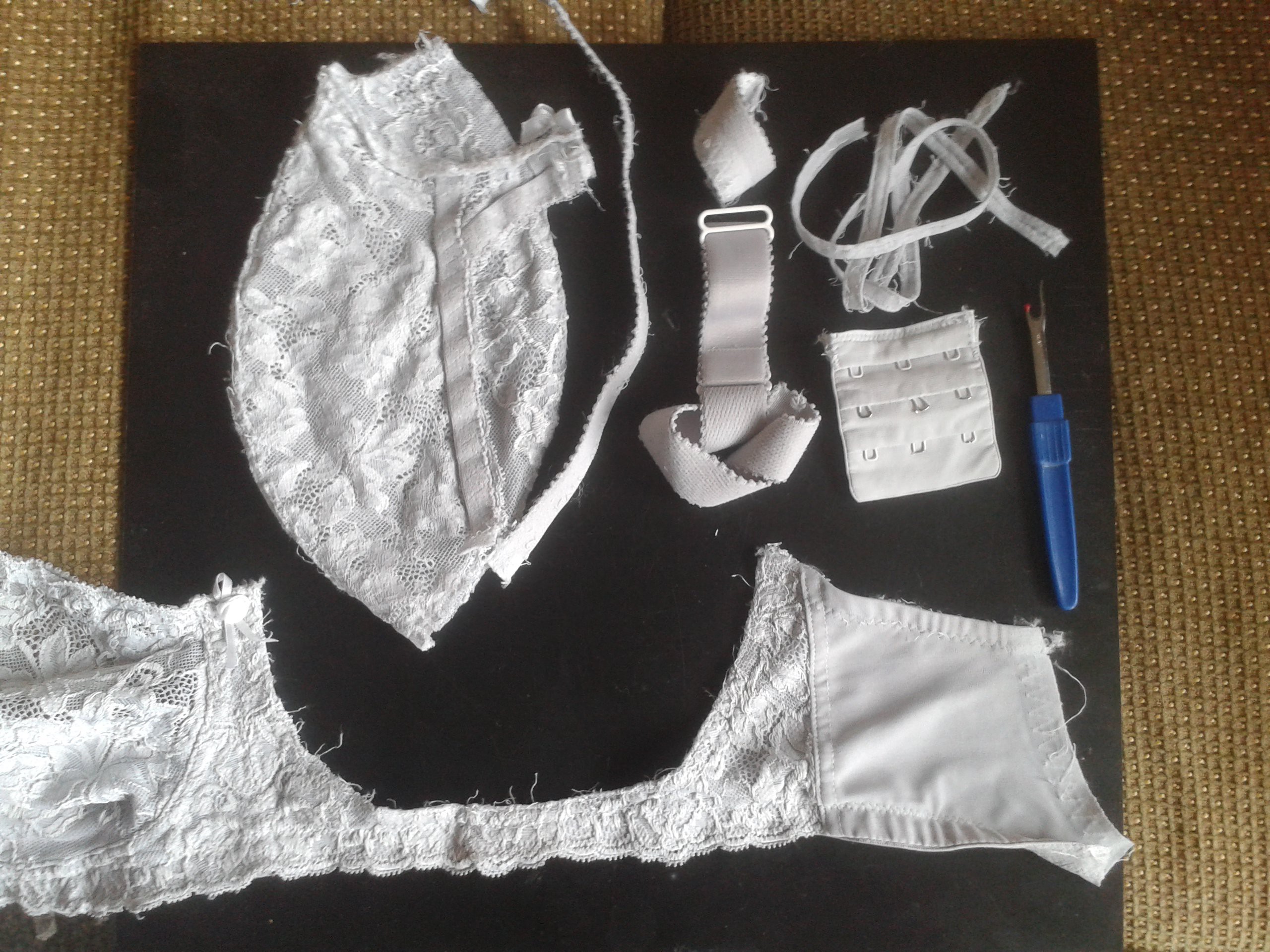

10 minutes with an old bra that Bea had destroyed the clasps on revealed the secrets I wanted to know. A seam ripper is the tool for this, just find an edge and carefully slice the major seams. Modern clothing is componentised and made in batches of parts on numerous machines, each setup for that part.

The sophistication here is obvious. Bra sizes have two metrics, bust and cup. This is done to calculate how far round the harness has to go, and how deep the cups need to be without a lot of detailed measurements, and adjustments are made by the shoulder straps, which would otherwise.

In order to mass-produce them, normal dress metrics are used, and the cup is calculated by adjusting the length of the curves forming the oval it folds into. This bra didnt fit quite well enough anyway, so I have adjusted the curve to fit her new bust measurement. This does change over time, luckily not by much now she's an adult. It should be stable by now.

The parts cut out after printing and templating them. The harness is folded in half, and the upper and lower cup parts separated. The fabric I found in my favourite Haberdashery, C&H Fabrics in Chichester.

The lace is a stretch polyester, and the backing is poly-cotton. I havent included any upholstery or bones. Those things are a menace, I wind up taking my washing machine apart to recover them, and they dont seem to do anything functional here.

All the strains in the fabric are taken up by elastic interfaced directly to the edge. There's a panel covering the side that also secures the edge of the lace so it doesnt tear as the panel stretches.

It's all done with a zig-zag stitch so that the threads can expand with the elastic, but the fabric only goes so far anyway.

Now the sun's up I can see to thread that bloody sewing machine. More later :-)

After a lot of screwing around with pins its nice to get in front of a machine and let that do all the hard work. Follow the seams around, removing the pins as you go. I'm going to put bias strips on all the seams. Normally these would be finished by rolling them inside and over-stitching, or just over-locking the edges of the hem together. Thats fine with outer clothing, but this needs to be flat and tidy inside and out.

A lot of tidying up in fact.

I have some metallic gold thread, I might use that to give the seams detail and finish the edges.

Pinning in the panels that the straps attach to. These have to be sturdy, two layers and elastic brought up into a triangle and a cross to take the strain from the straps.

Next time I'll use the plain zig-zag stitch, that looks a bit untidy. Good job its a prototype...

Mmm sexy knees. It still has pins in it... XD

After a bit of a tidy up and adding the fittings, not so bad.

Handy tip if you have to attach hooks and eyes or even buttons and have a sewing machine. Take the footplate off the feed arm so you can see where to put the needle through the eye of the part and use the buttonhole endstitch, its the same width as the diagonals between 4-hole buttons too. ;-)

Finally the Bias strip, which is a pain in the ass unless you buy it, or a biasing roller for the machine. I've done that by rolling the edge of the fabric and pinning it into a tube before stitching it over the seam. Once in place I ran a pair of snips round under the edge and snipped off the excess nice and tidy.

The biasing roller takes a strip of fabric and rolls it up, feeds it under the foot and then a special double needle and thread sews it to make parallel seams. I'll get one, they arent expensive and thats why professionally made stuff looks that tidy. Kind of cheating ;-)

This would need to be done carefully anyway to take a bra-wire. These are really only needed for smaller cup sizes, I've discovered after some research.

Just the straps to do now, simple tubes hemmed up and attached to the front, with elastic tails. I've decided, as I already know the dimensions, not to bother with adjustments - I'll just fit it and pin it while she is wearing it to get those right, and sew them in last of all.

According to the women I have managed to get advice from, a good bra should not need much elastic, and fit like a glove rather than stretch to fit anyway. Other than the cup on the old one, this is identical and should fit perfectly.

Morning.Star

Morning.Star