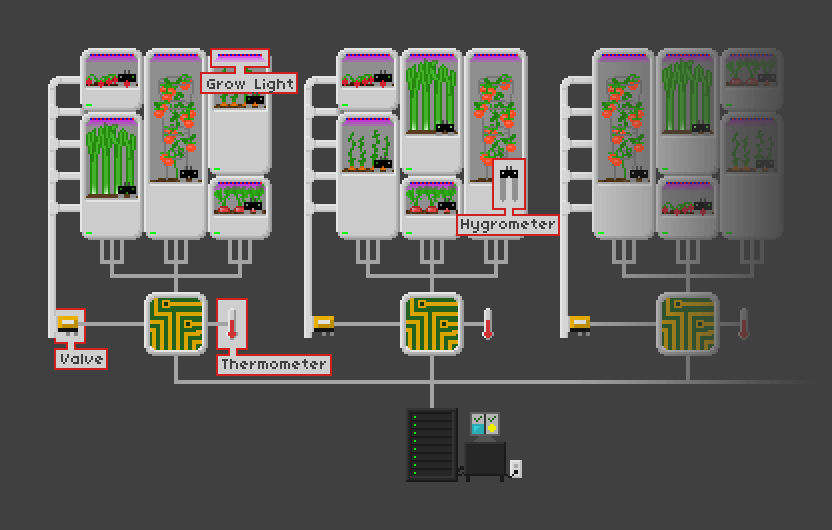

An image depicting the organizational structure I plan of having: I've thought a bit about the organizational structure of the project. I've come to the following conclusions:

I've thought a bit about the organizational structure of the project. I've come to the following conclusions:

- Modules should not "think on their own", but rather do the following things when the controller requests them:

- Enable/disable grow lights

- Give Hygrometer readings

- Change status indicators

- Report their unique ID, module size (!), plant type (?)

- Plumbing should be handled by the controller. It should control the valves based on the reported hygrometer status. It is probably a good idea to do one of the following:

- Have a valve for each module, directly controlled. Better precision in plant watering.

- Have a valve for each module, directly controlled. However, the valve power would run through the module, ensuring water doesn't flow unless a module is present. The controller can only turn all on or off. (Makes controllers easier, but probably not worth price of extra valves - 1. probably a better idea)

- Have a valve for each module, controlled by the module. The controller would probably tell the module whether it should water itself. The controller won't have to control so much with this approach.

- Have a valve for each section. In this case, missing modules would mean water leaks, but this can be averted by asking all positions for their modules (and the modules' sizes) and simply waiting until every position is populated. This might require dummy modules that don't permit water from entering to plug the water connection.

- Have a valve for each section. Figure out a way to (mechanically) shut off water flow if no module is present. Although this may be more preferable than 3., this would likely bulk up the frame more than I'd want. Some kind of lever connected to a spring pushing it to close the silicone tube

Should 1. - 3. be chosen, a transistor should probably be incorporated into the frame (near the valve) for switching the valve. - Grow Lights

While solutions 1. (controller controls directly), 3. (module controls for controller), or 4. (controller controls all directly) above could be applied to this (2. and 5. are pointless because no power is lost should a module not be attached.), I'm tending to 3. or 4. The reason it might be nice to control LED strips individually is the different growth cycles of different plants. Different seasons could be simulated for different plants this way.

Should 3. be chosen, a transistor should probably be incorporated into the module for switching the lights. - Thermometers

Probably connected to a microcontroller that can communicate directly with the section controller.

alpha_ninja

alpha_ninja

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.