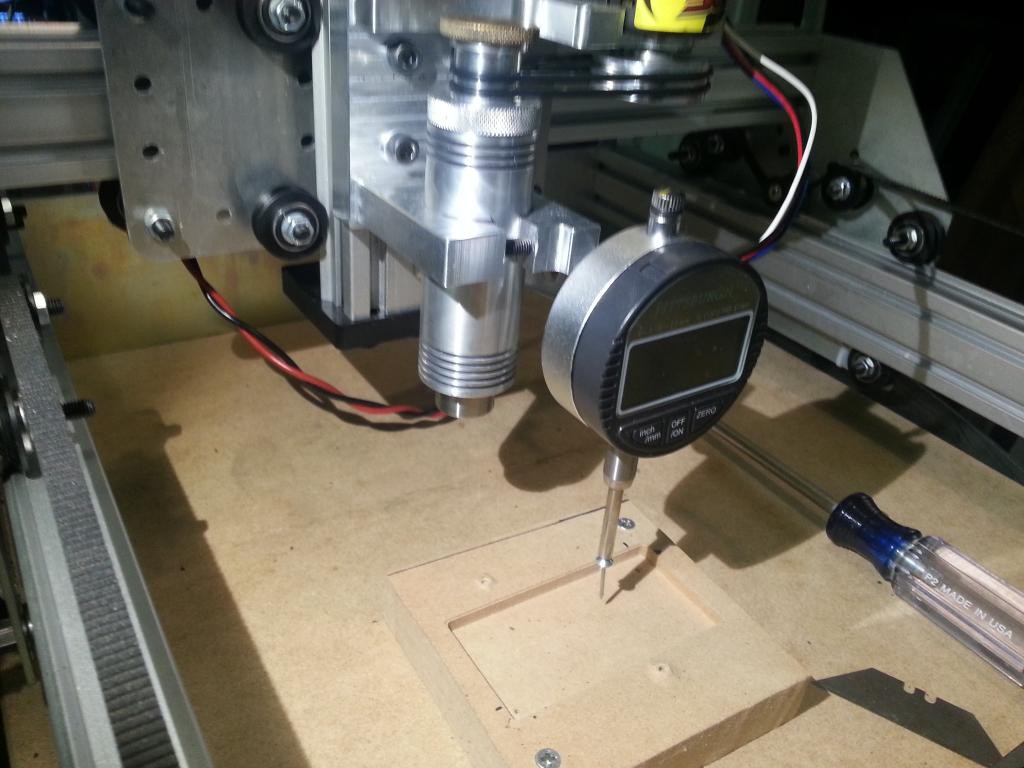

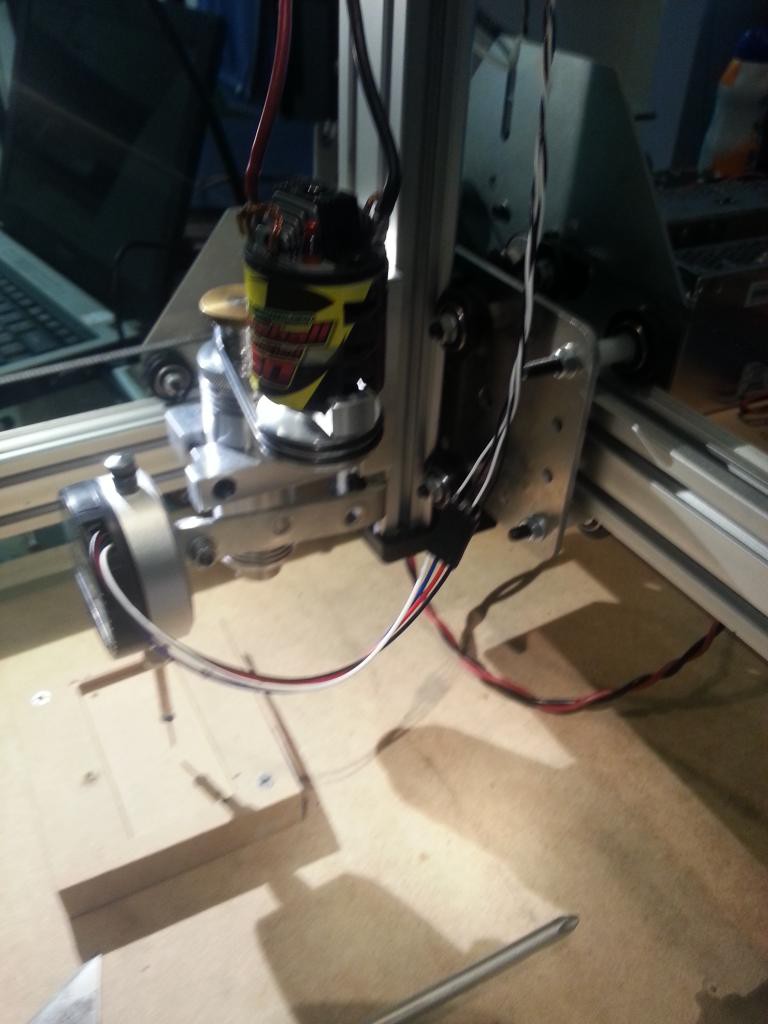

Problem: When using my CNC router to engrave or route circuit boards, I always tend to run in to problems with the work piece not being completely flat or parallel with machine axes. This leads to changes in the depth of cut which are typically quite shallow for these operations. This causes the copper layer to not be cut all the way through for circuit boards, or if engraving plastic, will cause the plastic to melt if the depth of cut increases too much. Solution:

Digital Dial Indicator CNC Surface Probe

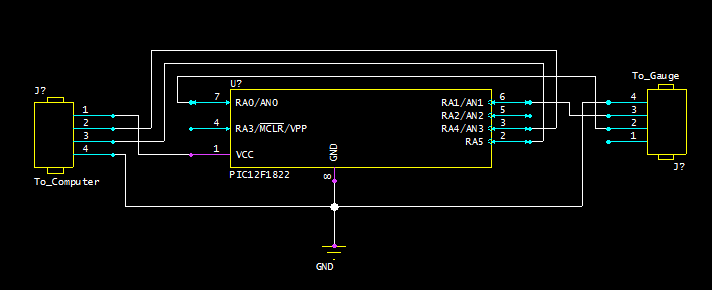

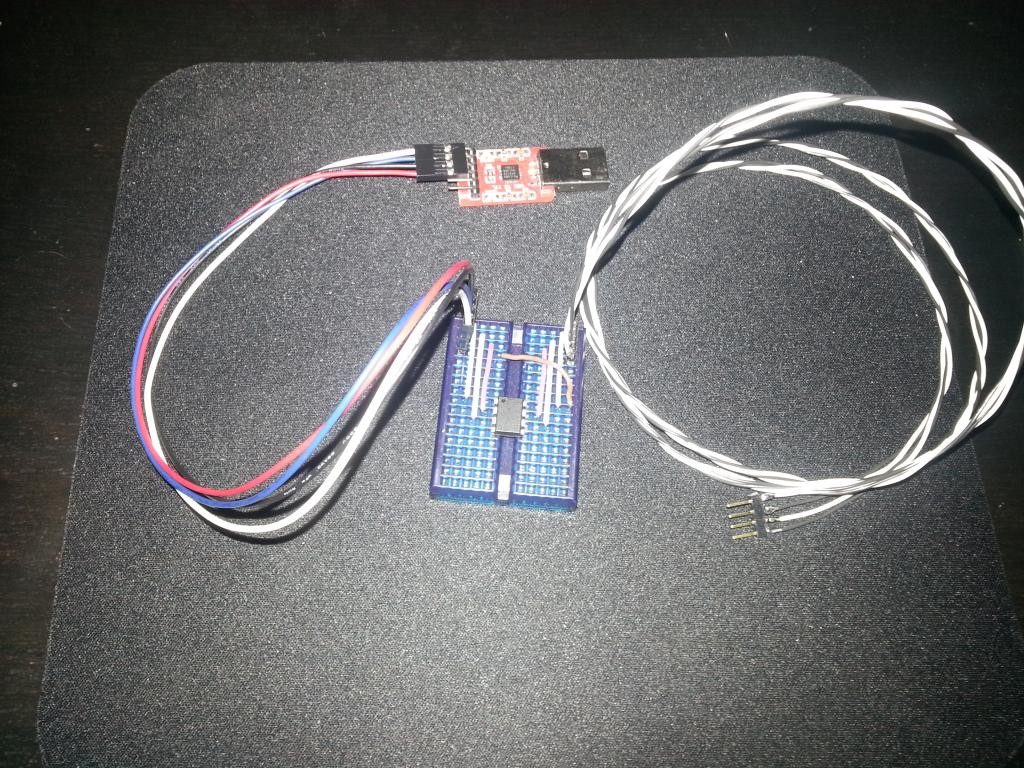

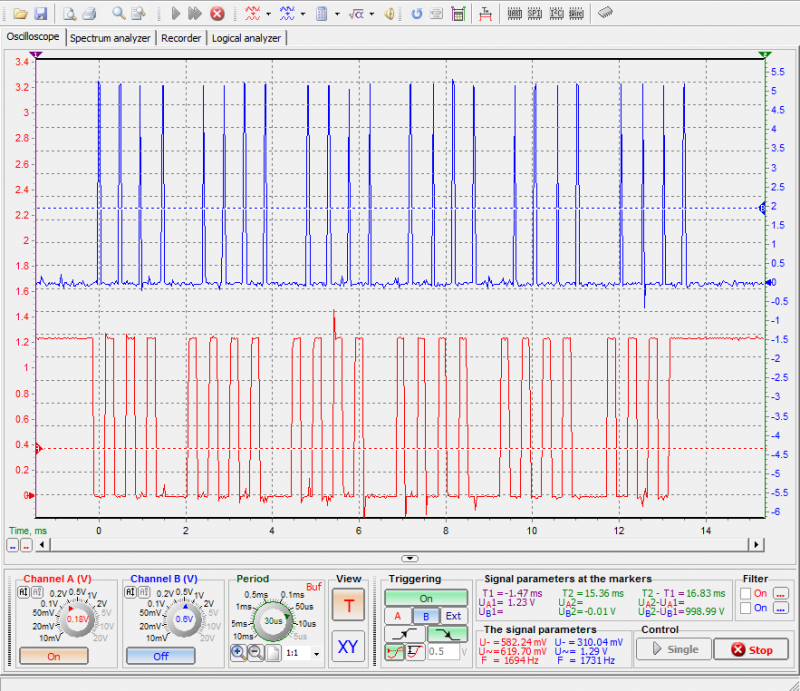

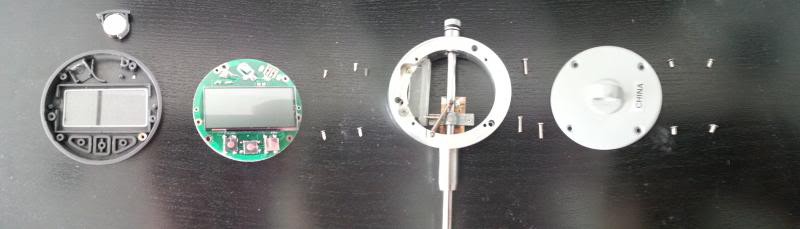

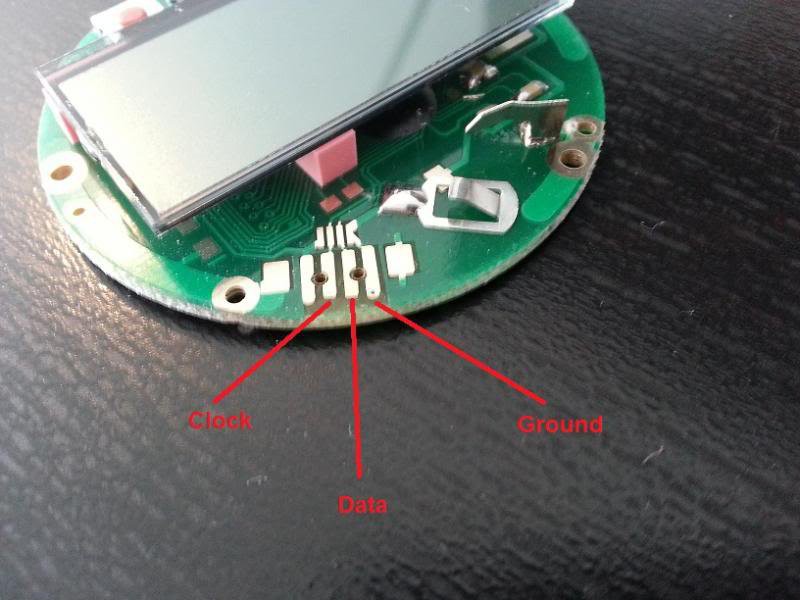

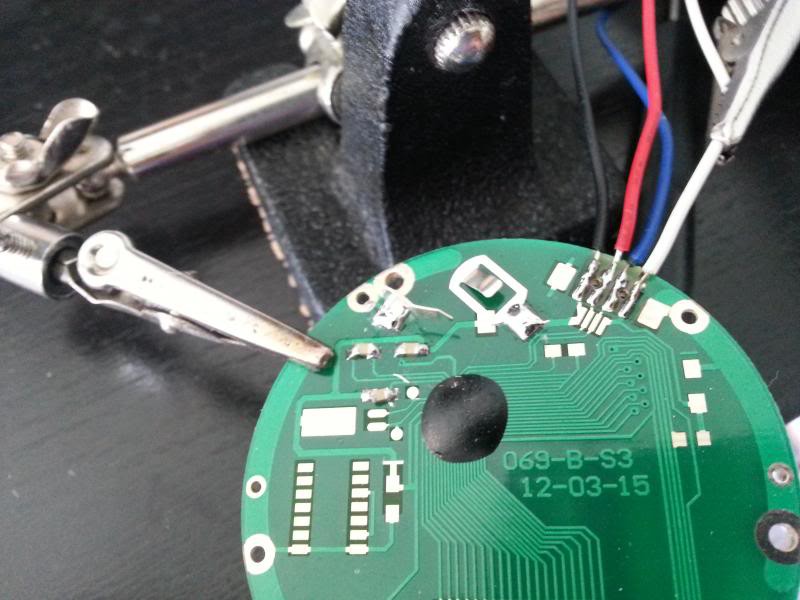

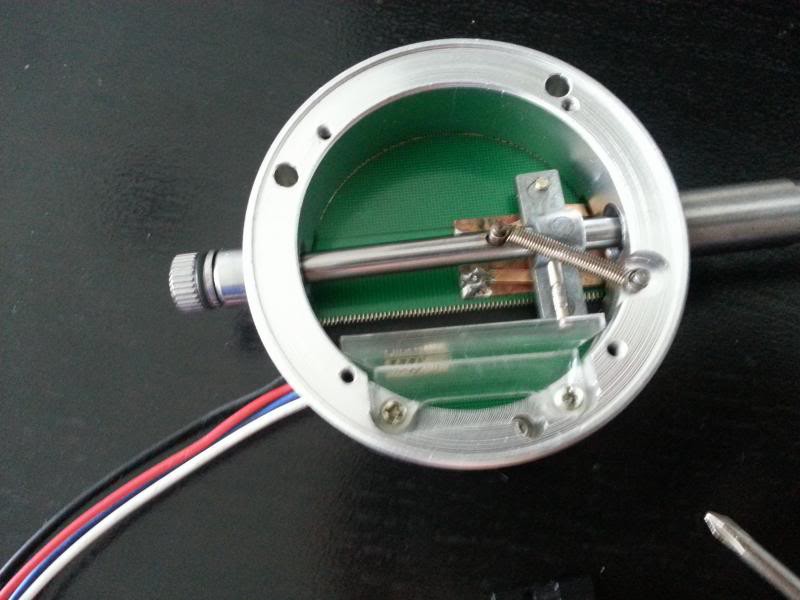

Using a cheap digital dial indicator interfaced with CNC machine to map 2D surface. Progress: Almost Done

Justin R.

Justin R.

BDM

BDM

George Gardner

George Gardner

Rowanon

Rowanon

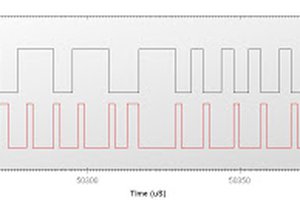

I have got this working up, but i am getting non linear data due to inductive noise in the system.

Dial didn't get reset though values received are started from zero in the middle of process. Any solution?